Hydrous zirconium oxide/strontium alginate composite gel bead, and preparation method application thereof

A technology of hydrated zirconia and composite gel, which is applied in alkali metal oxides/hydroxides, chemical instruments and methods, and combustible gas purification/transformation, etc., can solve the problems of difficult separation and easy loss of hydrated zirconia, and achieve Low price, easy separation, low filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

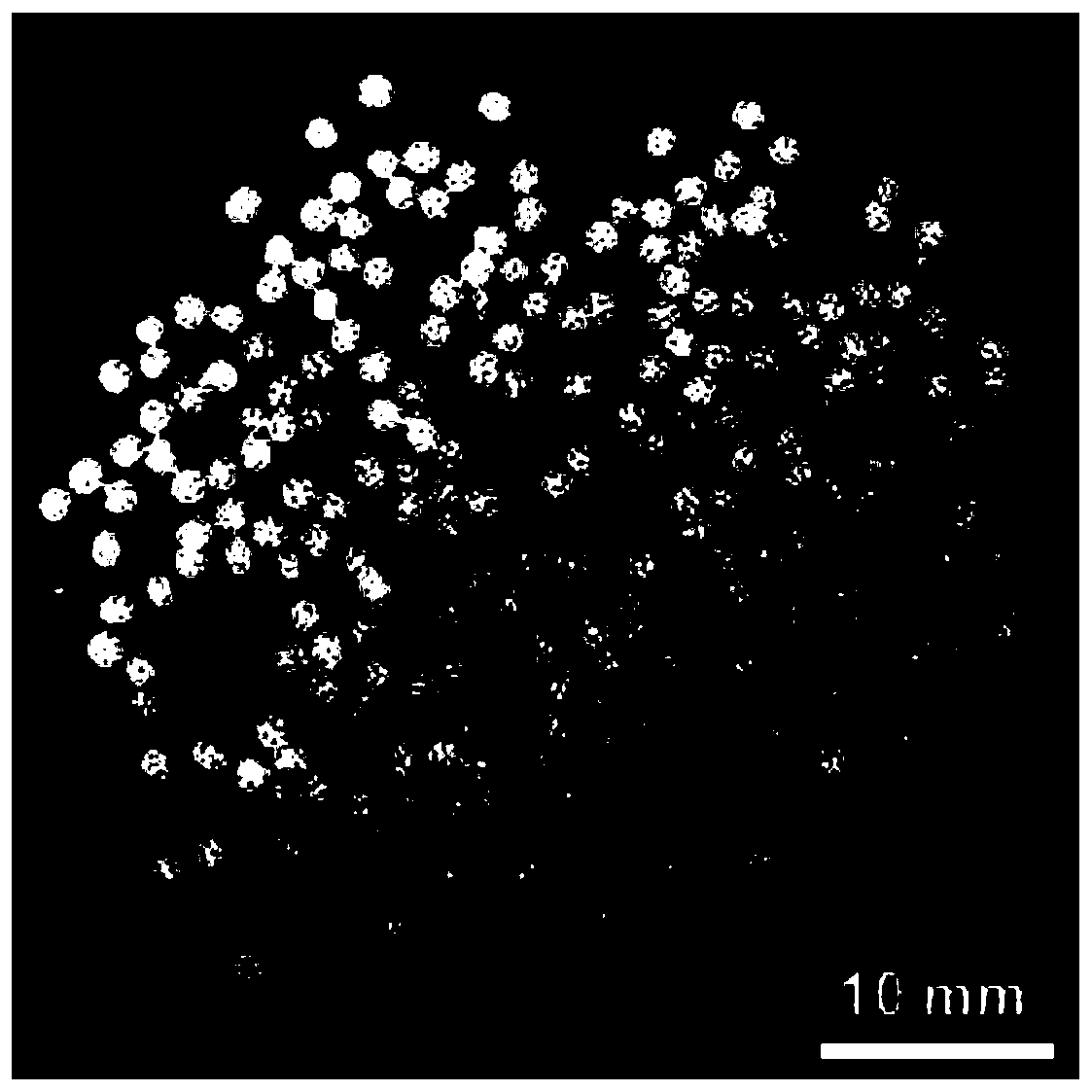

Image

Examples

Embodiment 1

[0053] A preparation method of hydrated zirconia / strontium alginate composite gel beads, comprising the steps of:

[0054] (1) Configure 400mL of ZrCl with a concentration of 0.025mol / L 4 Aqueous solution, in the state of stirring, drop by drop 1mol / L NaOH solution until the pH is 9-10. Continue to react for 10 minutes, stop stirring and let stand for 5 minutes until the white precipitate is complete, pour off the supernatant, add 300 mL of deionized water to wash, repeat the water wash 2 times, fully transfer all the precipitate into a 100 ml volumetric flask, and set the volume to the mark to obtain A hydrated zirconia colloidal dispersion with a concentration of 0.1mol / L.

[0055] (2) Weigh 4.0 g of sodium alginate and dissolve it in water to obtain a 2 wt % sodium alginate solution.

[0056] (3) Take 8mL of the sodium alginate solution prepared in step (2), and 12mL of the hydrated zirconia colloidal dispersion prepared in step (1), stir and mix to obtain the gel bead pr...

Embodiment 2

[0060] A preparation method of hydrated zirconia / strontium alginate composite gel beads, comprising the steps of:

[0061] (1) Prepare 100 mL of zirconium acetate aqueous solution with a concentration of 0.1 mol / L. While stirring, 5 mol / L NaOH solution was added dropwise until the pH was 9-10. Continue to react for 10 minutes, stop stirring and let stand for 5 minutes until the white precipitate is complete, pour off the supernatant, add 100 mL of deionized water to wash, repeat the water wash 2 times, fully transfer all the precipitate into a 100 ml volumetric flask, and set the volume to the mark to obtain A hydrated zirconia colloidal dispersion with a concentration of 0.1mol / L.

[0062] (2) Weigh 4.0 g of sodium alginate and dissolve it in water to obtain a 2 wt % sodium alginate solution.

[0063] (3) Take 8mL of the sodium alginate solution prepared in step (2), and 12mL of the hydrated zirconia colloidal dispersion prepared in step (1), stir and mix to obtain the gel ...

Embodiment 3

[0066] A preparation method of hydrated zirconia / strontium alginate composite gel beads, comprising the steps of:

[0067] (1) Prepare 100 mL of zirconium oxychloride aqueous solution with a concentration of 0.1 mol / L. In the state of stirring, 28wt% concentrated ammonia solution was added dropwise until the pH was 9-10. Continue to react for 10 minutes, stop stirring and let stand for 5 minutes until the white precipitate is complete, pour off the supernatant, add 100 mL of deionized water to wash, repeat the water wash 2 times, fully transfer all the precipitate into a 100 ml volumetric flask, and set the volume to the mark to obtain A hydrated zirconia colloidal dispersion with a concentration of 0.1mol / L.

[0068] (2) Weigh 2.0 g of sodium alginate and dissolve it in water to obtain a 1 wt % sodium alginate solution.

[0069] (3) Take 10mL of the sodium alginate solution prepared in step (2), and 10mL of the hydrated zirconia colloidal dispersion prepared in step (1), st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com