Method for measuring shale adsorption gas quantity and free gas quantity

A gas volume and shale technology, which is applied in the field of shale gas exploration and development, can solve the problems of restricting the efficient development of shale gas, the inability to distinguish the amount of adsorbed gas and free gas, and the unclear law of decline in the production difference of shale wells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

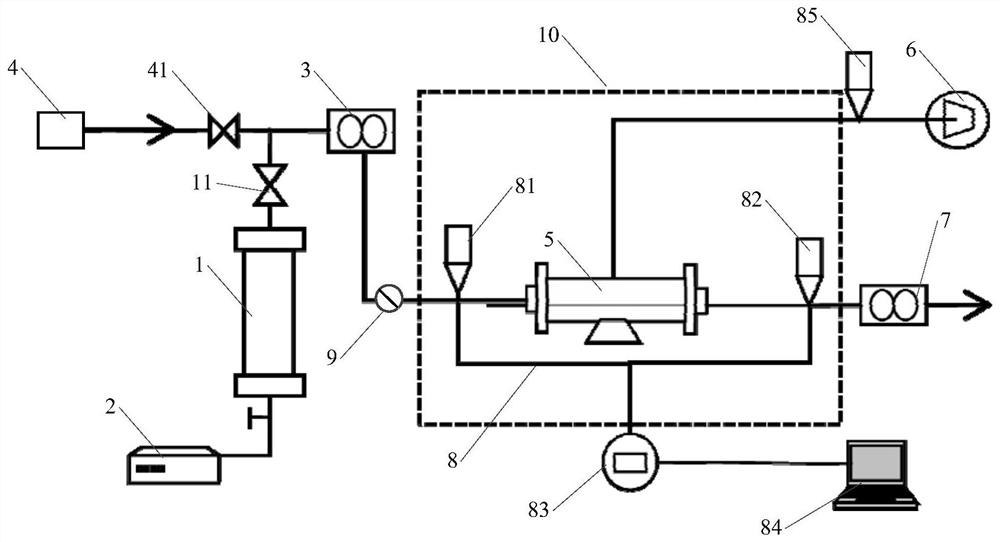

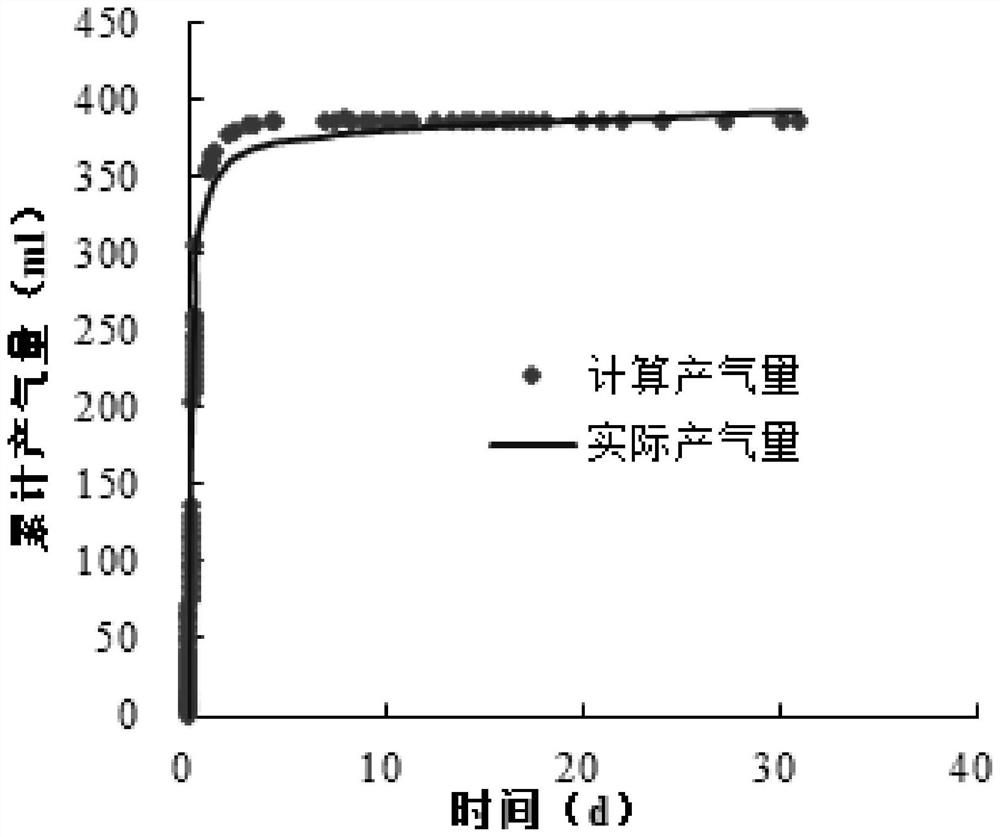

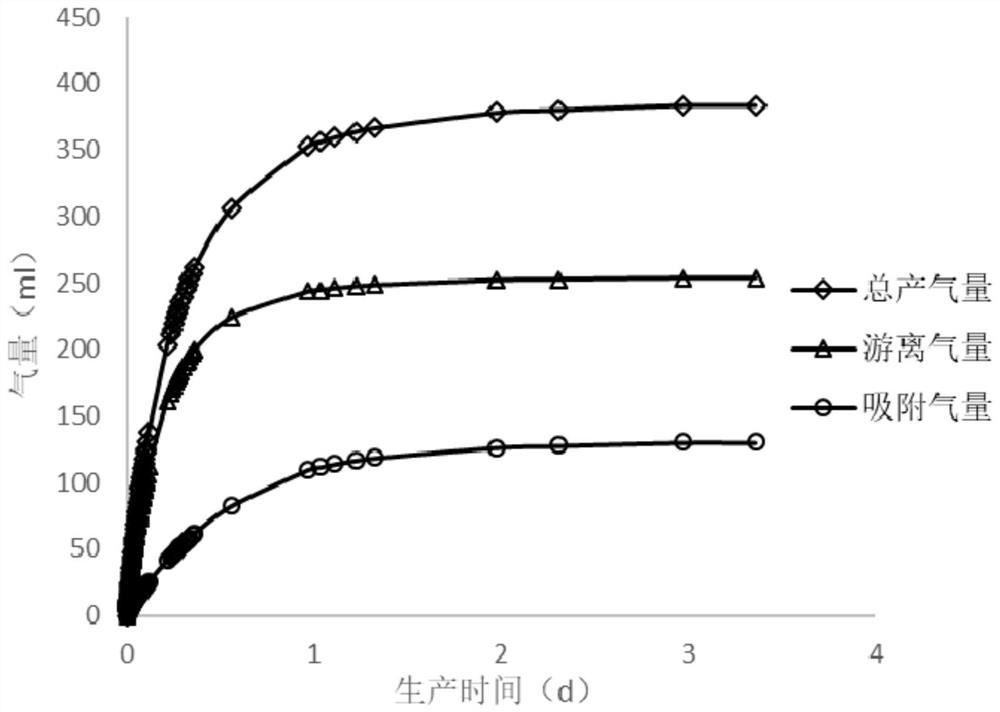

[0105] This embodiment provides a method for measuring the amount of shale adsorbed gas and free gas, using such as figure 1 The shown device comprises the steps of:

[0106] 1) Select shale core samples and measure basic physical parameters, including mass 75.7g, length 5cm, diameter 2.52cm, porosity 0.38, Langmuir volume 2.5m 3 / t and Langmuir pressure 3MPa;

[0107] 2) Conduct depletion development experiments on shale core samples, including:

[0108] Dry the shale core sample at 105°C for 48 hours, cool it to room temperature in a dry environment, put it into the core holder, and increase the confining pressure to 35MPa;

[0109] Turn on the gas source, inject methane gas into the shale core sample, record the pressure at the inlet end of the core holder through the first pressure sensor, and record the pressure at the outlet end of the core holder through the second pressure sensor, the pressure at the outlet end and the pressure at the inlet end reach Turn off the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com