Preparation method of compound nano film

A nano-film and film-forming technology, which is applied in the field of composite nano-film preparation, can solve the problems of disordered distribution, low controllability of conductive polymer thickness, difficulty in forming ultra-thin conductive polymer, etc., and achieve electrochemical activity High, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method is as follows:

[0040] ①Disperse carboxylated graphene oxide quantum dots in N,N-dimethylacetamide, the concentration of graphene oxide quantum dots is 5-7mg / ml, to form a graphene oxide quantum dot dispersion for LB film preparation ;

[0041] ②Add 3,4-ethylenedioxythiophene and ferric toluenesulfonate to absolute ethanol solvent to obtain poly-3,4-ethylenedioxythiophene solution for spin coating. The mass ratio of 3,4 ethylenedioxythiophene to iron toluenesulfonate is 1:4.

[0042] ③ Use a micro-sampler to extract 400-600 μl. ① Add the obtained solution dropwise to the surface of the ultrapure aqueous solution in the LB membrane tank. After N,N-dimethylacetamide volatilizes for 30 minutes, start to press the membrane. Graphite oxide quantum dot ene film has been formed at the / liquid interface;

[0043] ④ Control the sliding barrier of the LB film equipment to compress the graphene oxide film at a speed of 0.5-1 mm / min to a film pressure of ...

Embodiment 2

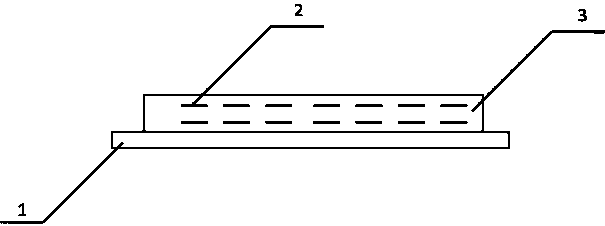

[0047] like figure 1 , the conductive polymer is polypyrrole.

[0048] The preparation process of the composite nanostructure is similar to Embodiment 1.

[0049] Thus, a composite nanofilm structure of polypyrrole-wrapped graphene oxide quantum dots was obtained.

Embodiment 3

[0051] like figure 1 , the conductive polymer is polyaniline.

[0052] The preparation process of the composite nanostructure is similar to Embodiment 1.

[0053] Thus, a composite nanofilm structure of polyaniline-wrapped graphene oxide quantum dots was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com