Coordination polymer porous material MAF-X8 and preparing method and application thereof

A MAF-X8, coordination polymer technology, applied in the field of coordination polymer porous material MAF-X8 and its preparation, can solve the problem of poor thermal stability and chemical stability, poor selectivity or anti-interference ability, adsorption equilibrium time Long and other problems, to achieve the effect of good water stability, short desorption time and low detection line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 Zinc pyrazole benzoate porous material MAF-X8 single crystal preparation

[0033] Ligand H 2 mpba (0.022g, 0.1mmol), Zn (NO 3 ) 2 ·6H 2 O (0.030g, 0.1mmol), N,N-dimethylacetamide (DMA, 0.1mL), ethanol (2.5mL), water (2.5mL) and trimethylbenzene (1.0mL) were added to the hydrothermal reaction In the kettle, it was heated to 120° C. for 3 days to obtain a colorless MAF-X8 single crystal with a yield of 54%.

Embodiment 2

[0034] Example 2 Preparation of a large amount of powder of zinc pyrazole benzoate porous material MAF-X8

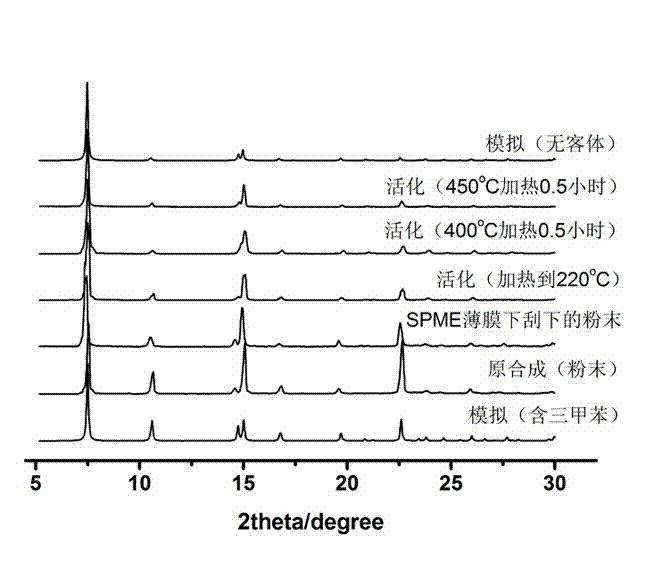

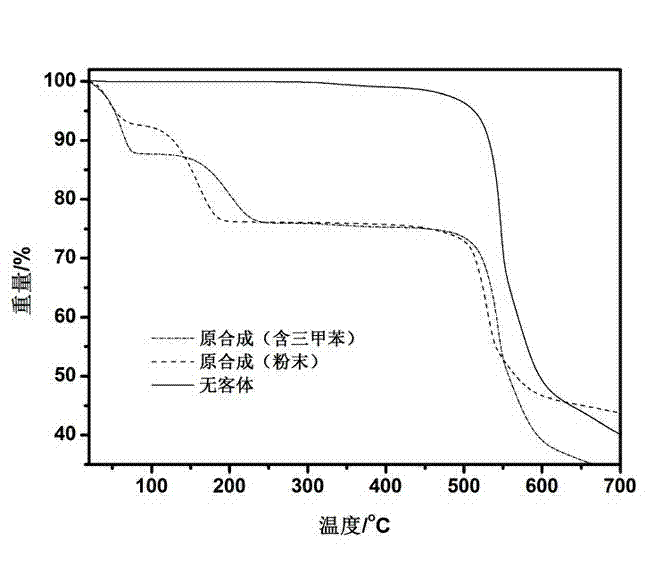

[0035] H 2 mpba (0.0108g, 0.5mmol), Zn (NO 3 ) 2 ·6H 2 O (0.150g, 0.5mmol), DMA (3.0mL), and methanol (9mL) were added together into a hydrothermal reaction kettle, heated to 120°C for 1 day, cooled to room temperature, washed with DMA and methanol to obtain White to pale yellow powder, yield 62%. The obtained powder was heated at 200°C for 30 min under a nitrogen atmosphere to remove the guest molecules, and the guest-free MAF-X8 could be obtained. The X-ray diffraction pattern of the product is shown in figure 2 .

Embodiment 3

[0036] Example 3 Structural Characterization of MAF-X8 Containing Guest Molecules and No Guest

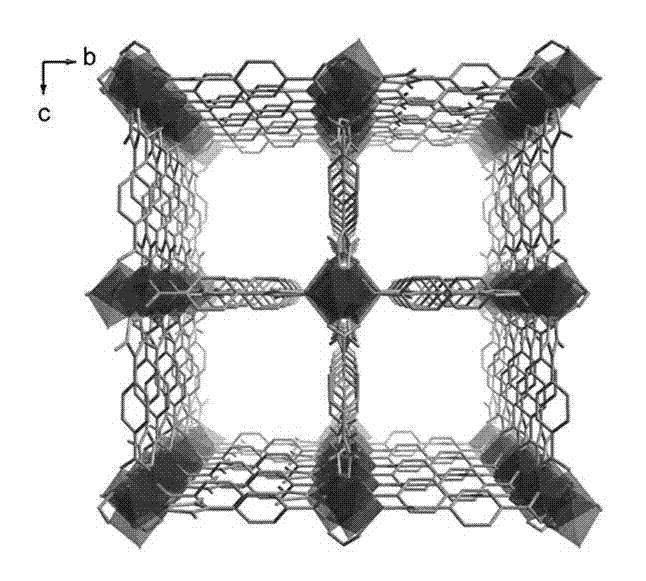

[0037] Single crystal X-ray diffraction data were collected on a Bruker Smart APEX CCD diffractometer, graphite monochromator, with X-rays, data were collected in ω-scan mode, and absorption correction was performed using the SADABS program. The direct method is used for analysis, and then the coordinates of all non-hydrogen atoms are obtained by the difference Fourier function method and the least square method, and finally the structure is corrected by the least square method. The organic hydrogen atoms of the compound are obtained by the theoretical hydrogenation method, and the hydrogen of the guest water molecule is found by the difference Fourier map. The calculation work is done on the PC using SHELXTL program. The detailed crystal determination data are shown in Table 1. structure see figure 1 .

[0038] Table 1

[0039]

[0040]

[0041] [a] R 1 =∑||F o |-|F ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com