Preparation method of hydrophobic MIL-101 chromium organometallic skeleton material

A technology of organic framework and chromium metal, which is applied in the field of preparation of hydrophobic MIL-101 chromium metal organic framework material, can solve the problems of poor moisture resistance and achieve the effect of weakening binding force, good adsorption performance and large adsorption accommodation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

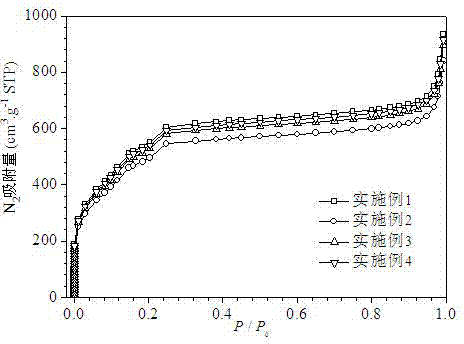

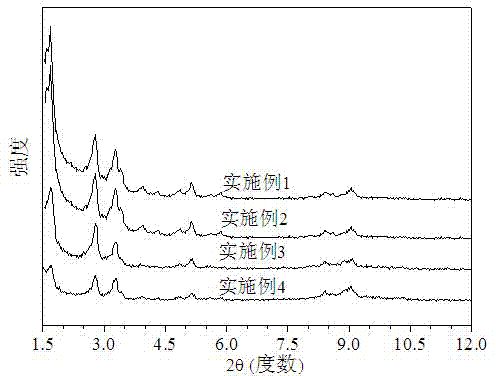

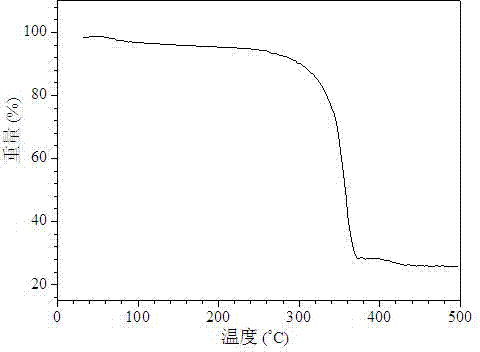

[0041] 1.20gCr(NO 3 ) 3 9H 2 O and 0.65g of 1,4-naphthalene dicarboxylic acid were dissolved in 27mL of water, 0.026g of hydrofluoric acid and 0.090g of acetic acid were added, and placed on a magnetic stirrer and stirred for 30min to make the mixed solution uniform to obtain a precursor solution; Put it into a stainless steel high-pressure reaction kettle, seal it and put it into a temperature-programmed furnace for hydrothermal reaction. The temperature-raising program is set as follows: heat the solution from room temperature to 210°C at 5°C / min, react at a constant temperature at 210°C for 10 hours, and then heat it at 0.4°C The cooling rate of ℃ / min lowers the temperature of the reaction solution to 35°C; after the reaction, the precipitate is obtained, and the precipitate is washed with deionized water, dimethylformamide and ethanol for 2 to 3 times respectively, and the temperature of the reaction solution is 3000r / min Centrifuge for 25 minutes, filter, and dry the lo...

Embodiment 2

[0043] 1.50gCr(NO 3 ) 3 9H 2 O and 0.54g of 1,4-naphthalene dicarboxylic acid were dissolved in 22.5mL of water, 0.025g of hydrofluoric acid and 0.075g of acetic acid were added, and placed on a magnetic stirrer and stirred for 50min to make the mixed solution uniform to obtain a precursor solution; then the precursor solution Put it into a stainless steel high-pressure reactor, seal it, and put it into a temperature-programmed furnace for hydrothermal reaction. The temperature-rising program is set as follows: heat the solution from room temperature to 220°C at 5°C / min, react at a constant temperature at 220°C for 12 hours, and then The cooling rate of 0.4°C / min reduces the temperature of the reaction solution to 35°C; after the reaction, the precipitate is obtained, and the precipitate is washed with deionized water, dimethylformamide and ethanol for 2 to 3 times respectively, and the speed is 5000r / min Centrifuge for 30 minutes, filter, and dry the lower layer product at ...

Embodiment 3

[0045] 1.20gCr(NO 3 ) 3 9H 2 O and 0.52g of 1,4-naphthalene dicarboxylic acid were dissolved in 21.6mL of water, 0.024g of hydrofluoric acid and 0.072g of acetic acid were added, and placed on a magnetic stirrer and stirred for 40min to make the mixed solution uniform to obtain a precursor solution; then the precursor solution Put it into a stainless steel high-pressure reactor, seal it, and put it into a temperature-programmed furnace for hydrothermal reaction. The temperature-rising program is set as follows: heat the solution from room temperature to 220°C at 5°C / min, react at a constant temperature at 220°C for 10 hours, and then The cooling rate of 0.4°C / min lowers the temperature of the reaction solution to 35°C; after the reaction, the precipitate is obtained, and the precipitate is washed with deionized water, dimethylformamide and ethanol for 2 to 3 times respectively, and the speed is 4000r / min Centrifuge for 35 minutes, filter, and dry the lower layer product at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com