Preparation method of small-crystal-grain SAPO-34 molecular sieve

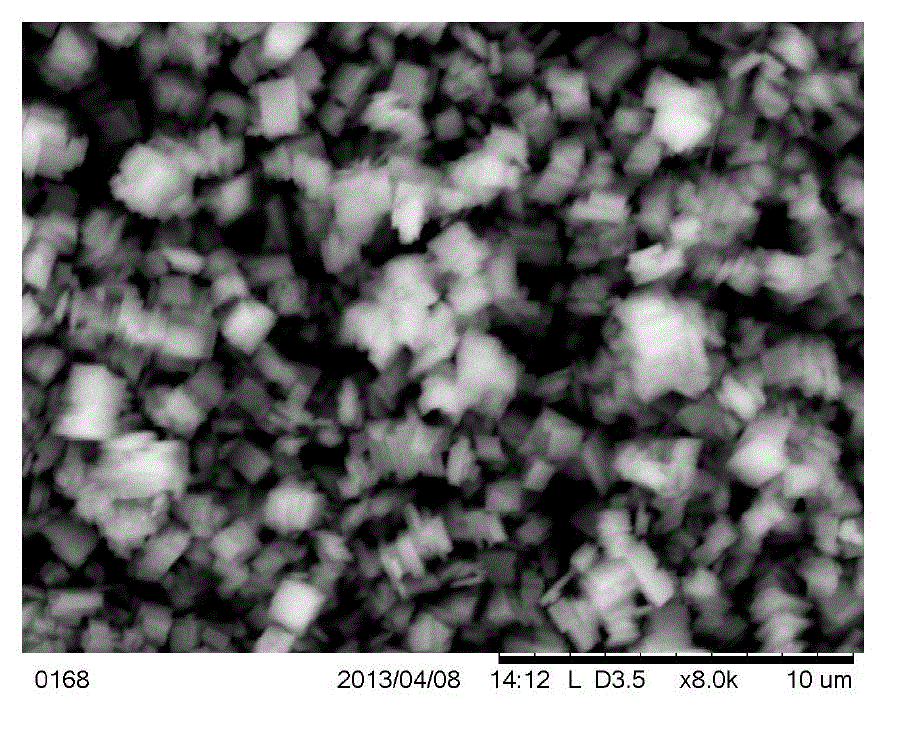

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali exchange phosphate, etc., can solve the problem of lack of further research on the influence of aging time on product properties, and achieve excellent catalytic effect and uniform dispersion , the effect of small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

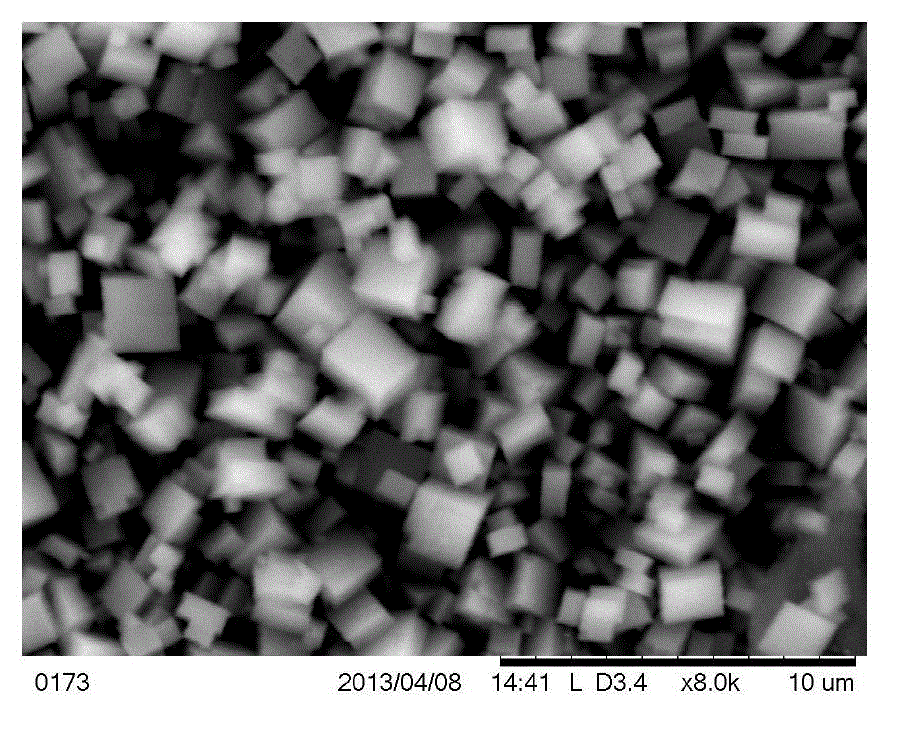

[0023] A kind of preparation method of small-grain SAPO-34 molecular sieve adopts dynamic hydrothermal method to synthesize series SAPO-34 molecular sieve, and the steps are as follows:

[0024] ⑴First, add a certain amount of aluminum source (pseudoboehmite, with a content of 65% to 75%) into deionized water under stirring at room temperature, and then add a certain amount of silicon source (neutral silica sol, with a content of 40 %) and stir well. Then slowly add a certain amount of phosphorus source (orthophosphoric acid, the content is 85%), and continue to stir evenly; then slowly add a certain amount of template agent (tetraethylammonium hydroxide aqueous solution, the content is 25%), increase the stirring speed to make solution into a homogeneous gel.

[0025] (2) Stir the homogeneous gel on a homogenizer at 10,000 rpm for 30 minutes, then place it in an oven at different temperatures for aging for a certain period of time;

[0026] (3) Transfer the gel to a dynamic...

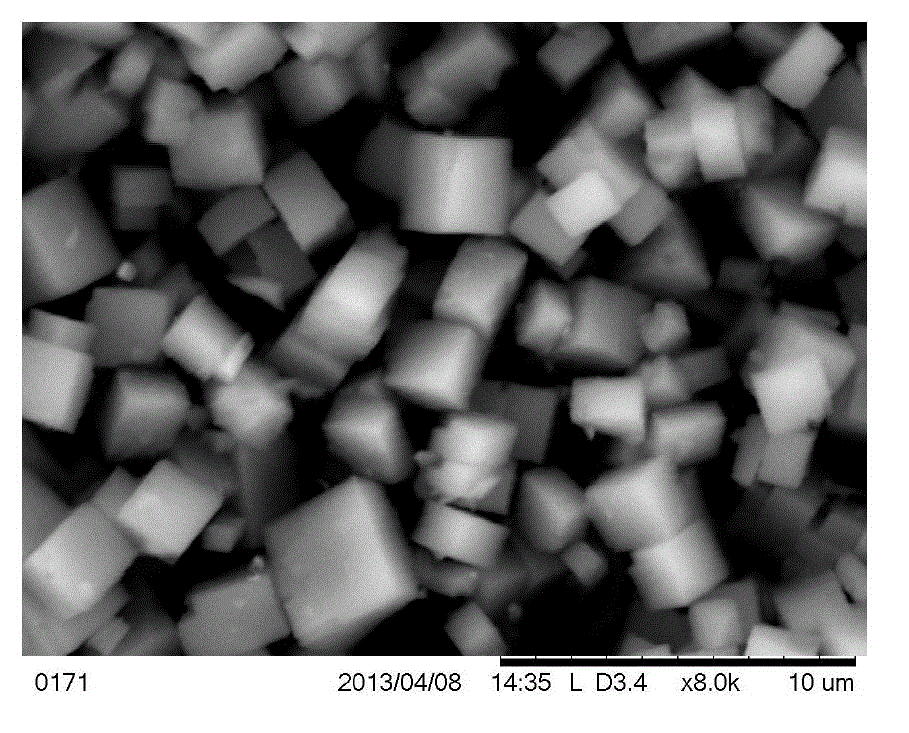

Embodiment 1

[0034] A preparation method of small grain SAPO-34 molecular sieve, the steps are as follows:

[0035] (1) First, add 22.76 grams of pseudoboehmite (65% to 75% content) into 99.83 ml deionized water while stirring at room temperature, then add 3.81 ml neutral silica sol (40% content) and stir well. Slowly add 20.53 milliliters of orthophosphoric acid (content is 85%), continue to stir evenly. Then slowly add 172.79 milliliters of tetraethylammonium hydroxide aqueous solution (content is 25%), increase stirring speed to make the solution into a uniform gel.

[0036] (2) Stir the homogeneous gel on a homogenizer at 10,000 rpm for 30 minutes, then place it in a refrigerator (about 3-5°C) for 18 hours of aging;

[0037] (3) Transfer the gel to a dynamic high-pressure reactor, set a certain speed, and crystallize at 200°C for 28 hours. After the crystallization is complete, cool it quickly with cold water. Finally, the reacted mixture is separated, washed, and dried. The molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com