Catalyst for synthesizing ethylbenzene through ethylene and benzene liquid phase method and preparation and application of catalyst

A technology for synthesizing ethylbenzene and catalysts, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic performance, low strong acid density, side reactions, etc., and achieve high catalytic activity and catalytic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

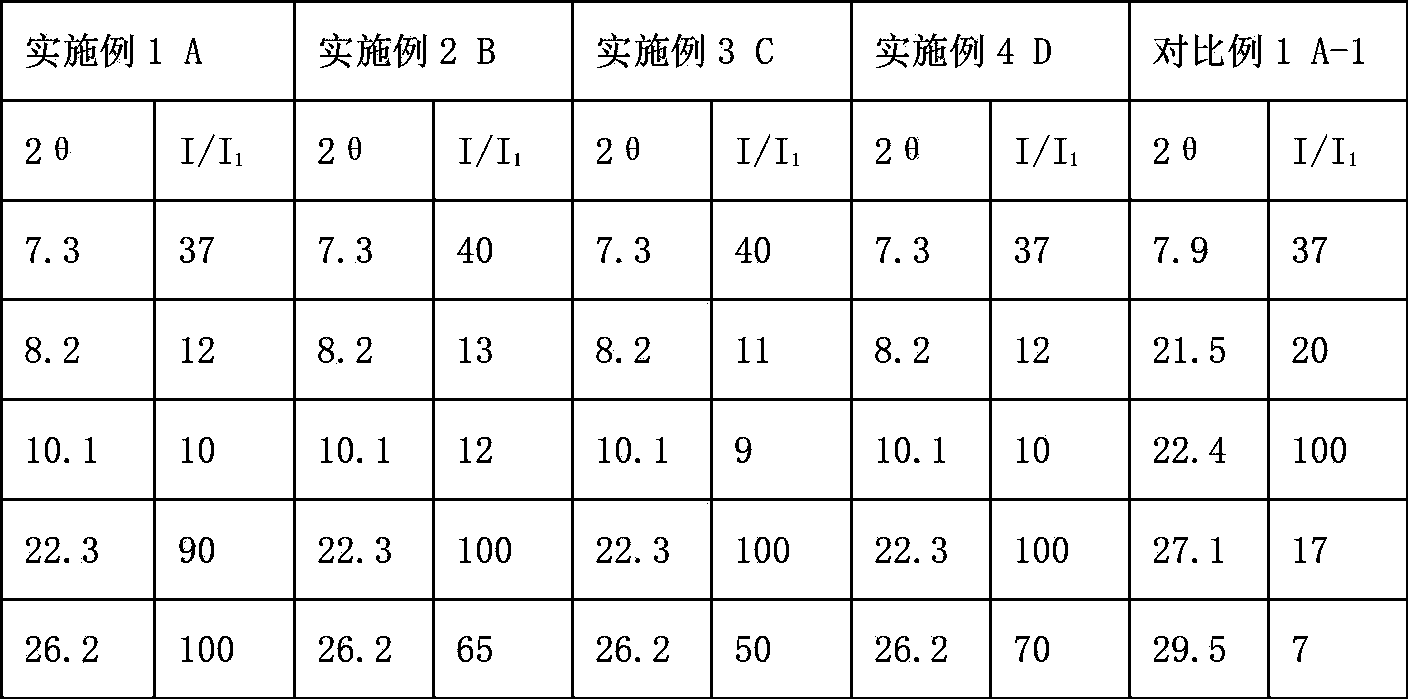

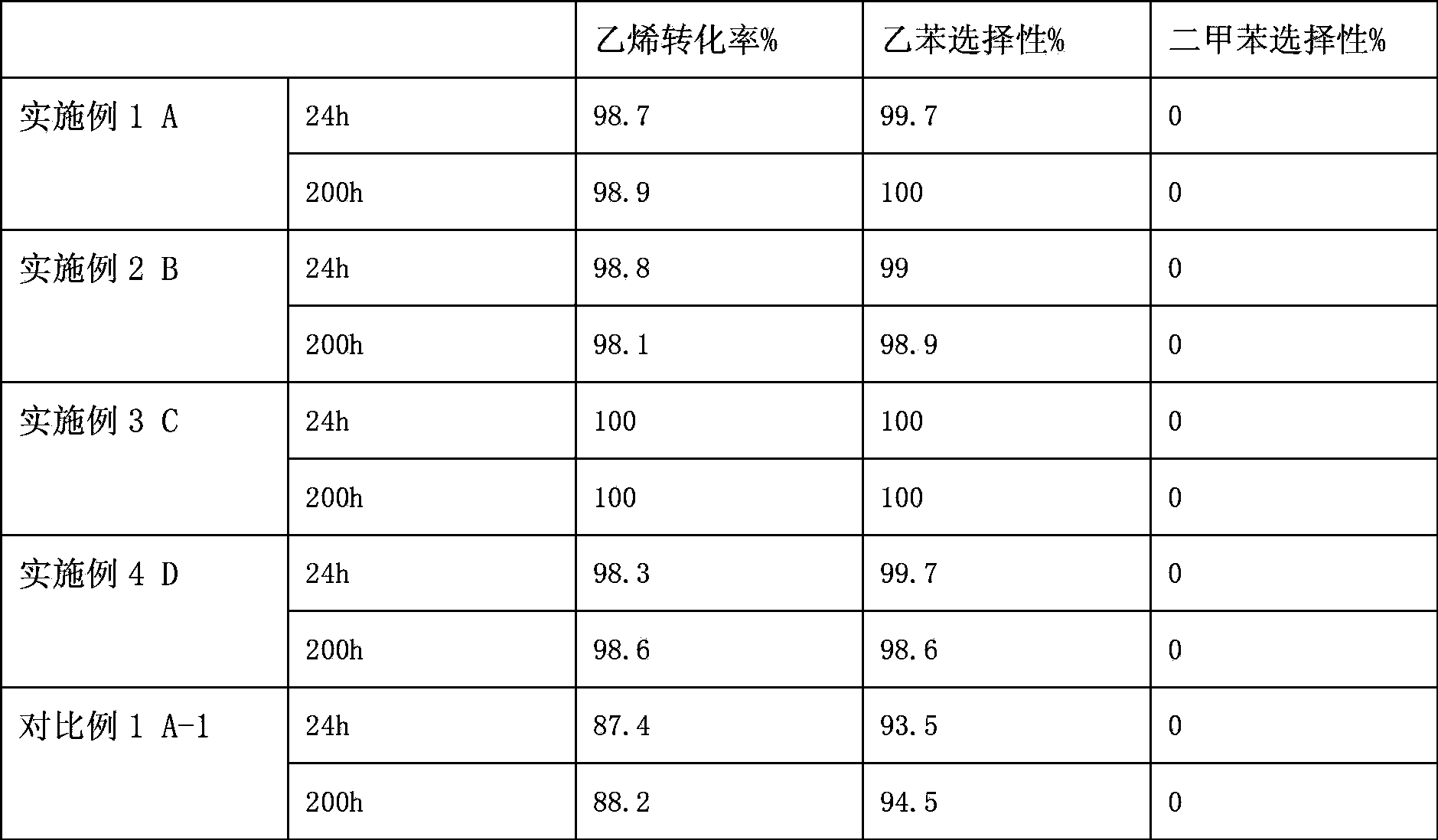

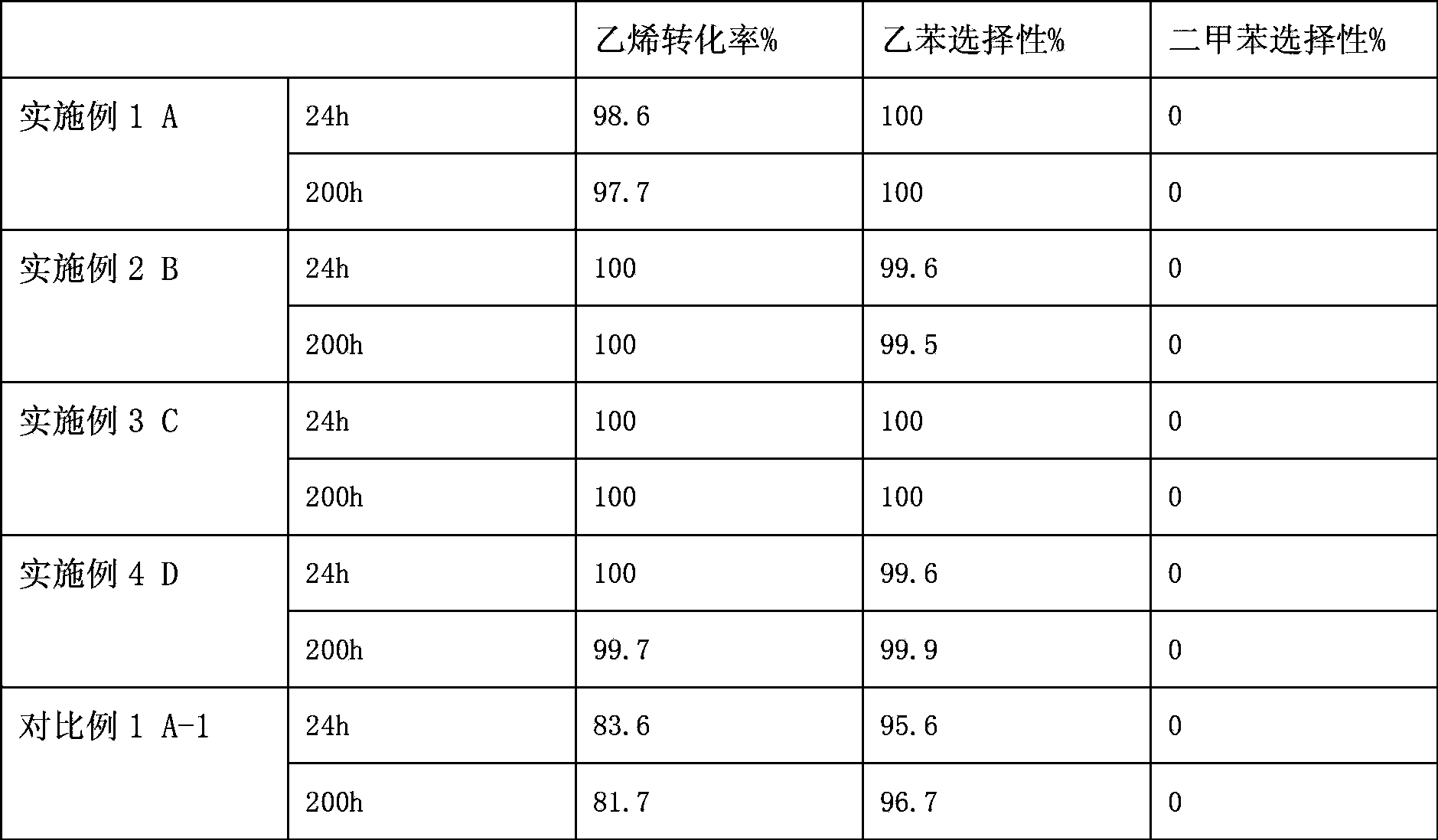

Embodiment 1

[0017] At 40°C, dissolve 100 grams of MCM-49, 1.2 grams of sodium hydroxide, and 50 grams of tetraethylammonium bromide in 108 ml of deionized water, add 100 grams of silica sol under stirring, and continue stirring for 10 minutes to make it uniform sol-gel. Move it into a crystallization kettle and crystallize at 140°C. After 96 hours, the obtained product was filtered and washed with distilled water until pH=10. Then it was dried at 110°C for 12 hours and calcined at 560°C for 4 hours to obtain MCM-49-β molecular sieve. The obtained molecular sieve was then ion-exchanged in a 20% (wt) ammonium nitrate solution, then dried at 110°C for 12 hours, and calcined at 560°C for 4 hours to obtain molecular sieve material A.

Embodiment 2

[0019] At 20°C, dissolve 100 grams of MCM-49, 7 grams of sodium hydroxide, and 300 grams of tetraethylammonium bromide in 500 ml of deionized water, add 300 grams of silica sol under stirring, and continue stirring for 5 minutes to make it uniform sol-gel. Move it into a crystallization kettle and crystallize at 150°C. After 48 hours, the crystallization was completed, and the obtained product was filtered and washed with distilled water until pH=10. Then it was dried at 110°C for 12 hours and calcined at 580°C for 4 hours to obtain MCM-49-β molecular sieve. The obtained molecular sieve was then ion-exchanged in an ammonium nitrate solution with a concentration of 15% (wt), then dried at 110°C for 12 hours, and calcined at 580°C for 4 hours to obtain molecular sieve material B.

Embodiment 3

[0021] At 60°C, dissolve 100 grams of MCM-49, 12 grams of sodium hydroxide, and 380 grams of tetraethylammonium bromide in 550 ml of deionized water, add 250 grams of silica sol under stirring, and continue stirring for 10 minutes to make it uniform sol-gel. Move it into a crystallization kettle and crystallize at 150°C. After 48 hours, the obtained product was filtered and washed with distilled water until pH=10. Then it was dried at 110°C for 12 hours and calcined at 580°C for 4 hours to obtain MCM-49-β molecular sieve. The obtained molecular sieve was then ion-exchanged in an ammonium nitrate solution with a concentration of 10% (wt), then dried at 110°C for 12 hours, and calcined at 580°C for 4 hours to obtain molecular sieve material C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com