Pyrazole strongly acidic ionic liquid catalyst and application thereof

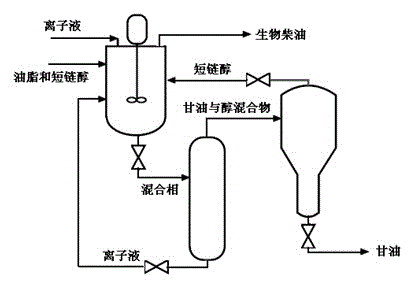

An ionic liquid and catalyst technology, applied in the field of green renewable energy, can solve the problems of increasing cost, limited acidity of ionic liquid, restricting large-scale application, etc., and achieve the effects of increasing acid density, shortening reaction time, and reducing application cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

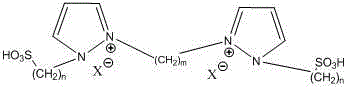

[0026] Embodiment 1: This pyrazole strongly acidic ionic liquid catalyst is bispyrazole butane sulfonic acid ionic liquid catalyst, and its chemical structural formula is as follows:

[0027] where X is HSO 4 - , m=4; n=4.

[0028] The synthetic method of this ionic liquid catalyst is as follows:

[0029] 1) Dissolve 0.55mol pyrazole and 0.5mol sodium hydroxide in 50ml ethanol solvent, stir and react at 70°C for 10h, cool and filter, wash the filter residue three times with ether (50ml×3), and dry it in a vacuum oven at 50°C for 5h to obtain pyrazole Sodium azole intermediate.

[0030] 2) Dissolve 0.5 mol sodium pyrazole and 0.25 mol 1,4-dibromobutane in 50 ml ethanol, mix well, stir and reflux for 10 h, filter, wash the filtrate three times with ether, and vacuum dry to obtain bispyrazole intermediate.

[0031] 3) 0.5 mol of 1,4-butane sultone was added to the toluene solution of bispyrazole, mixed and stirred for 8 hours, and the toluene was removed by rotary evaporati...

Embodiment 2

[0034] Embodiment 2: this pyrazole strong acid ionic liquid catalyst is dihydrogen phosphate bispyrazole butane sulfonic acid ionic liquid catalyst, and chemical structural formula is as follows:

[0035] where X is H 2 PO 4 - , m=3; n=4.

[0036] The synthetic method of this ionic liquid catalyst is as follows:

[0037] 1) Dissolve 0.55mol pyrazole and 0.5mol sodium hydroxide in 50ml ethanol solvent, stir and react at 70°C for 10h, cool and filter, wash the filter residue three times with ether (50ml×3), and dry it in a vacuum oven at 50°C for 5h to obtain pyrazole Sodium azole intermediate.

[0038] 2) Dissolve 0.5mol sodium pyrazole and 0.25mol 1,3-dibromopropane in 50ml ethanol, mix well, stir and reflux for 10h, filter, wash the filtrate three times with ether, and vacuum dry to obtain bispyrazole intermediate.

[0039] 3) 0.5 mol of 1,4-butane sultone was added to the toluene solution of bispyrazole, mixed and stirred for 8 hours, and the toluene was removed by rota...

Embodiment 3

[0042] Embodiment 3: this pyrazole strongly acidic ionic liquid catalyst is bispyrazole propane sulfonic acid ionic liquid catalyst, and the chemical structural formula is as follows:

[0043] , where X is Cl - , m=4; n=3.

[0044] The synthetic method of this ionic liquid catalyst is as follows:

[0045] 1) Dissolve 0.55mol pyrazole and 0.5mol sodium hydroxide in 50ml ethanol solvent, stir and react at 70°C for 10h, cool and filter, wash the filter residue three times with ether (50ml×3), and dry it in a vacuum oven at 50°C for 5h to obtain pyrazole Sodium azole intermediate.

[0046] 2) Dissolve 0.5 mol sodium pyrazole and 0.25 mol 1,4-dibromobutane in 50 ml ethanol, mix well, stir and reflux for 10 h, filter, wash the filtrate three times with ether, and vacuum dry to obtain bispyrazole intermediate.

[0047] 3) 0.5 mol of 1,3-propane sultone was added to the toluene solution of bispyrazole, mixed and stirred for 8 hours, and the toluene was removed by rotary evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com