Method for preparing hydro-demetalization catalyst

A hydrodemetallization and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve carrier distribution dispersion, poor mechanical strength, preparation process Complexity and other issues, to achieve high activity and activity stability, improve activity stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

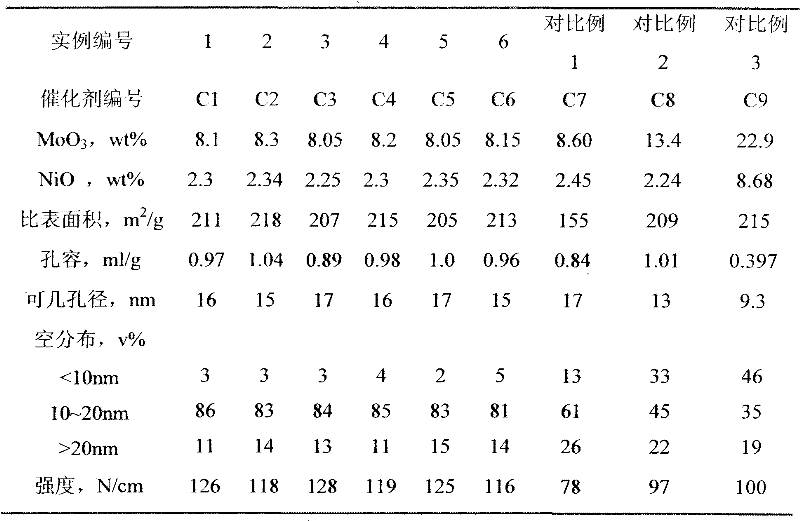

example 1

[0025] Weigh 30 g of the first pseudo-boehmite dry rubber powder (produced by Shenyang Catalyst Factory, with an alumina dry basis content of 65%) with a pore volume of 0.5 to 0.8 ml / g, and the second one with a pore volume of 0.85 to 1.5 ml / g. A kind of pseudo-boehmite dry rubber powder (produced by Shandong Qilu Petrochemical Company, with an alumina dry basis content of 70%) 70g is mixed evenly, and 1.5g concentration of 65% by weight is added to the above-mentioned mixed pseudo-boehmite dry rubber powder. Nitric acid, 2g of safflower powder and 75g of deionized water are fully kneaded, extruded into a clover-shaped strip with a diameter of 1.8mm on a screw extruder, dried at 120°C for 3 hours, and the dried shaped product is roasted at a temperature of 700°C After 3 hours, an alumina support was obtained. Weigh 100 grams of the above-mentioned alumina carrier, add 150ml Mo-Ni-NH 3 solution (with MoO 3 12.0 wt%, NiO3.0 wt%) impregnated for 2 hours, filtered off excess sol...

example 2

[0027]With example 1, just the first kind of pseudo-boehmite dry rubber powder (production of Shenyang Catalyst Factory, alumina dry basis content 65%) charging amount is 5g, the second kind of pseudo-boehmite dry rubber powder (Shandong Qilu Petroleum Co., Ltd. Produced by a chemical company, with an alumina dry basis content of 70%), the feed amount is 95g, and the dry catalyst is roasted for 3 hours in a mixed atmosphere with a water vapor content of 50V% at 650°C to obtain the hydrodemetallization catalyst C2 of the present invention.

example 3

[0029] With example 1, just the first kind of pseudo-boehmite dry rubber powder (production of Shenyang Catalyst Factory, alumina dry basis content 65%) charging amount is 50g, the second kind of pseudo-boehmite dry rubber powder (Shandong Qilu Petroleum Co., Ltd. Produced by a chemical company, with an alumina dry basis content of 70%), the feed amount is 50g, and the dry catalyst is roasted for 3 hours in a mixed atmosphere with a water vapor content of 40V% at 550°C to obtain the hydrodemetallization catalyst C3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com