Pt-Pd bimetallic catalyst for NO oxidation and preparation method of Pt-Pd bimetallic catalyst

A bimetallic catalyst, precious metal technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as failure to meet regulatory requirements, achieve outstanding NO oxidation capacity, wide conversion temperature window, and easy steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

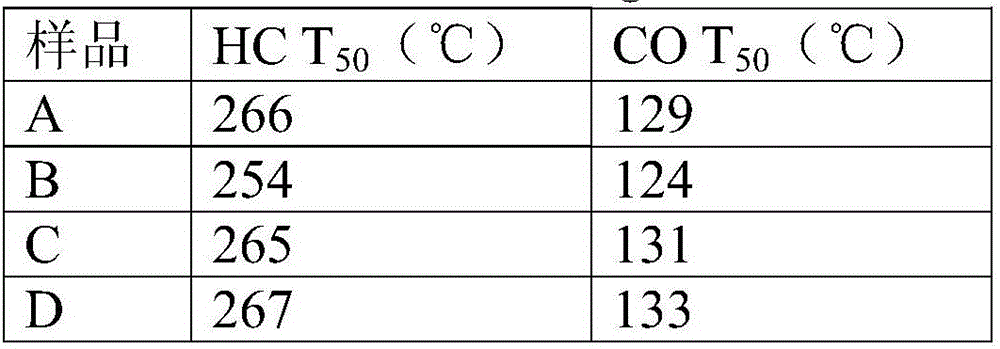

Embodiment 1

[0018] Example 1: A Pt-Pd bimetallic catalyst for NO oxidation, the catalyst carrier is cordierite honeycomb ceramic, the volume is 1.101 liters, and the pore density is 400 mesh / square foot; the coating contains manganese-aluminum composite oxide And molecular sieve, the coating amount is 120 g / L; the coating amount of the precious metal used is 1.4 g / L, and the mass ratio of the precious metal Pt to the precious metal Pd is 3:1.

[0019] The preparation method includes the following steps:

[0020] (1) Preparation of manganese-aluminum composite oxide by equal volume impregnation method: Manganese-aluminum composite oxide is prepared by equal volume impregnation method. Weigh 588 grams of alumina powder, weigh 39 grams of manganese nitrate and dissolve it to prepare an aqueous solution with saturated adsorption capacity of the alumina used, then add the manganese nitrate solution dropwise to the alumina powder and continue stirring for 6 hours; Then it was allowed to stand and a...

Embodiment 2

[0025] The specific preparation method is basically the same as that of Example 1, except that in the manganese-aluminum composite oxide used, the mass ratio of manganese element to alumina is 1:24 to obtain catalyst B.

Embodiment 3

[0027] The specific preparation method is basically the same as that of Example 1, except that in the manganese-aluminum composite oxide used, the mass ratio of manganese element to alumina is 3:47, to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com