Ceria-zirconia composite oxide-loaded perovskite type catalyst with sulfur resistance and preparation method of catalyst

A composite oxide and perovskite-type technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Structure and other issues, to achieve the effect of improving sulfur resistance, reducing direct contact with sulfur, and strong sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

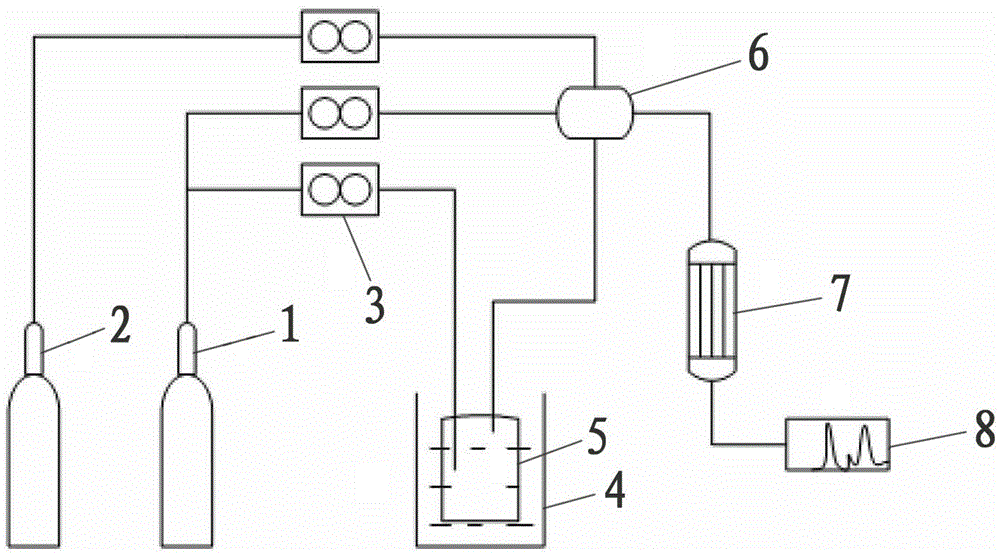

Method used

Image

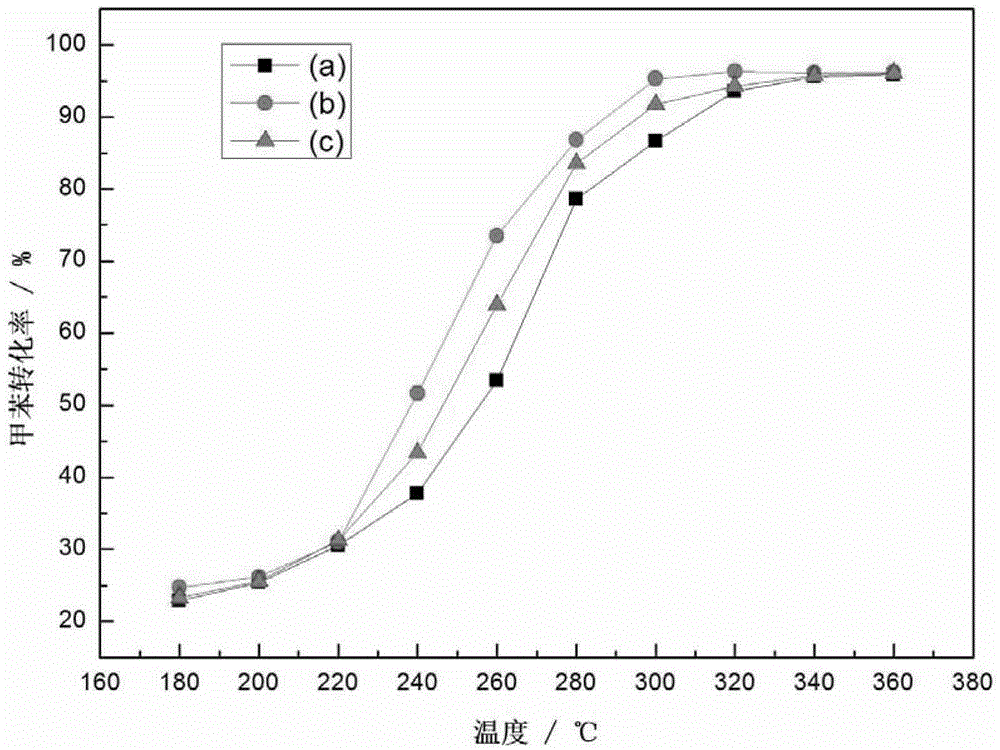

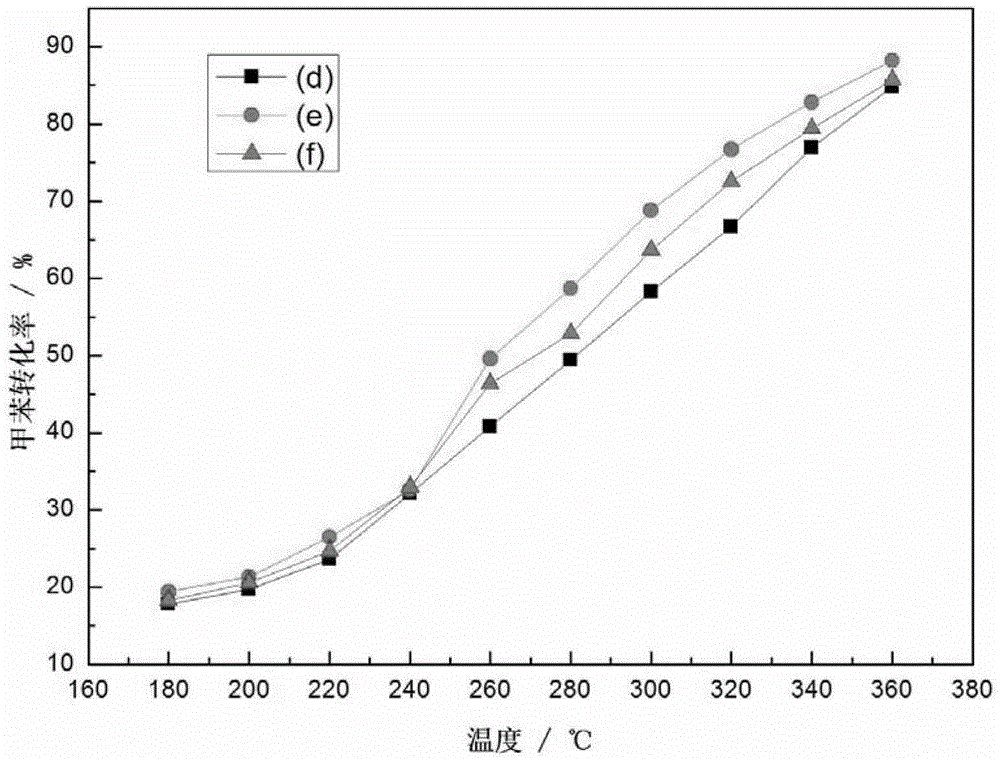

Examples

Embodiment 1

[0034] Embodiment 1: the catalyzer described in this embodiment comprises following composition:

[0035] Active component: Perovskite La 0.9 Sr 0.1 MnO 3 , accounting for 5%wt% of the catalyst;

[0036] Auxiliary agent: Pt, accounting for 0.01wt% of the catalyst;

[0037] Carrier: Ce 0.9 Zr 0.1 o 2 Composite oxides account for 94.99wt% of the catalyst.

[0038] Concrete preparation steps are:

[0039] Step (1): A certain concentration of Ce(NO 3 ) 3 , Zr(NO 3 ) 3 The precursor solution was mixed, and Ce was prepared by co-precipitation method 0.9 Zr 0.1 o 2 composite oxides;

[0040] Step (2): Prepare the deionized aqueous solution of manganese nitrate, strontium nitrate and lanthanum nitrate according to the ratio La:Sr:Mn=0.9:0.1:1, add Ce after mixing 0.9 Zr 0.1 o 2 Composite oxide carrier, stirred evenly, impregnated for 24 hours;

[0041] Step (3): The mixture in step (2) was first dried at 90°C for 12 hours, and then transferred to a muffle furnace fo...

Embodiment 2

[0046] Embodiment 2: the catalyst described in this embodiment, comprises following composition:

[0047] Active component: Perovskite La 0.8 Sr 0.2 MnO 3 , accounting for 14wt% of the catalyst;

[0048] Auxiliary agent: Pt, accounting for 0.05wt% of the catalyst;

[0049] Carrier: Ce 0.7 Zr 0.3 o 2 Composite oxides account for 85.95% of the catalyst.

[0050] Concrete preparation steps are:

[0051] Step (1): Add a certain concentration of Ce(NO 3 ) 3 , Zr(NO 3 ) 3 The precursor solution was mixed, and Ce was prepared by co-precipitation method 0.7 Zr 0.3 o 2 composite oxides;

[0052] Step (2): Prepare the deionized aqueous solution of manganese nitrate, strontium nitrate and lanthanum nitrate according to the ratio La:Sr:Mn=0.8:0.2:1, add Ce after mixing 0.7 Zr 0.3 o 2 Composite oxide carrier, stirred evenly, impregnated for 24 hours;

[0053] Step (3): The mixture in step (2) was first dried at 100°C for 15 hours, and then transferred to a muffle furnace...

Embodiment 3

[0057] Embodiment 3: the catalyst described in this embodiment comprises following composition:

[0058] Active component: Perovskite La 0.6 Sr 0.4 MnO 3 , accounting for 10wt% of the catalyst;

[0059] Auxiliary agent: Pt, accounting for 0.5wt% of the catalyst;

[0060] Carrier: Ce 0.5 Zr 0.5 o 2 Composite oxides account for 89.5wt% of the catalyst.

[0061] Step (1): A certain concentration of Ce(NO 3 ) 3 , Zr(NO 3 ) 3 The precursor solution was mixed, and Ce was prepared by co-precipitation method 0.5 Zr 0.5 o 2 composite oxides;

[0062] Step (2): Prepare the deionized aqueous solution of manganese nitrate, strontium nitrate and lanthanum nitrate in proportion La:Sr:Mn=0.6:0.4:1, mix and add Ce 0.5 Zr 0.5 o 2 Composite oxide carrier, stirred evenly, impregnated for 24 hours;

[0063] Step (3): The mixture in step (2) was first dried at 110°C for 18 hours, and then transferred to a muffle furnace for calcination at 700°C in air for 3 hours to obtain (La 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com