Cerium zirconium aluminum composite oxides sosoloid with a mesopore structure and method for preparing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

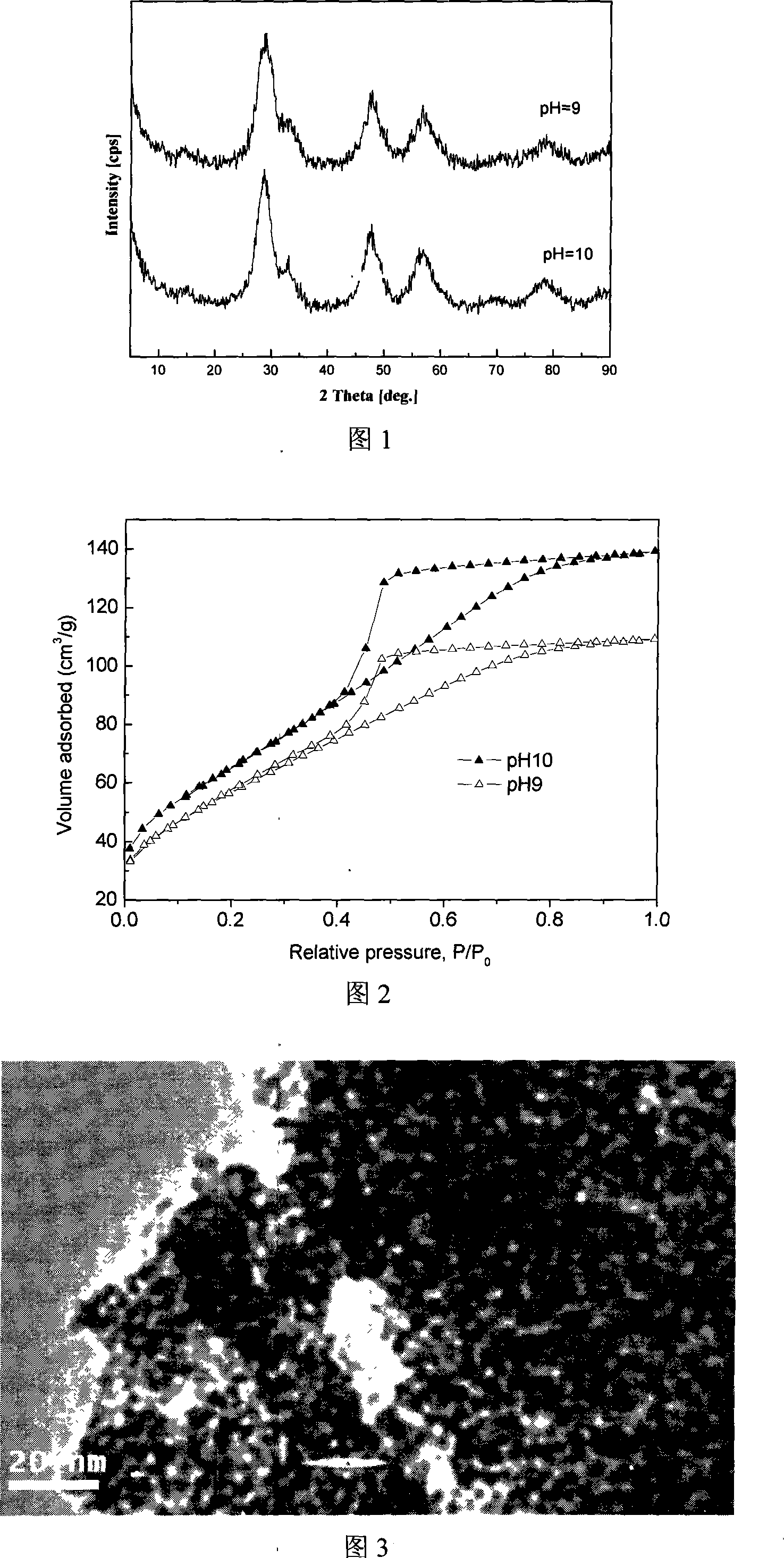

[0014] At room temperature, weigh 6 mmol of CTMACl, dissolve it in 200 mL of deionized water, and stir vigorously for 15 minutes, then add the calculated amount of Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O and Al(NO 3 ) 3 ·6H 2 O (molar ratio 3.5:1.0:0.5), continue to stir for 30 minutes, add 0.2M NaOH solution to a pH value of 10, stir the resulting suspension for 12 hours, age at 90°C for 3 hours, wash with hot water, and suction filter, Mesoporous Ce prepared by drying at 110°C for 6 hours and calcined at 450°C for 4 hours 0.7 Zr 0.2 Al 0.1 o 2 The solid solution, its XRD, nitrogen adsorption and desorption analysis, and TEM analysis are shown in Figure 1-3.

Embodiment 2

[0016] The mixed solution in Example 1 was adjusted to pH 9 with NaOH, and the others were the same as in Example 1. The prepared mesoporous Ce 0.7 Zr 0.2 Al 0.1 o 2 The XRD and nitrogen adsorption-desorption analysis of solid solution samples are shown in Figure 1-2.

Embodiment 3

[0018] Change the mol ratio of Ce / Zr / Al in the reaction solution in Example 1 to 3: 1: 1, and others are the same as Example 1, and prepare mesoporous Ce 0.6 Zr 0.2 Al 0.2 o 2 solid solution samples. Its XRD, nitrogen adsorption, and transmission electron microscope images are similar to those shown in Figures 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com