Nano Cerium-zirconium base compound oxide and preparation process thereof

A composite oxide, cerium zirconium technology, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve the problems of high cost and complicated operation steps, and achieve high storage/release capacity and oxygen storage capacity. High, small grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

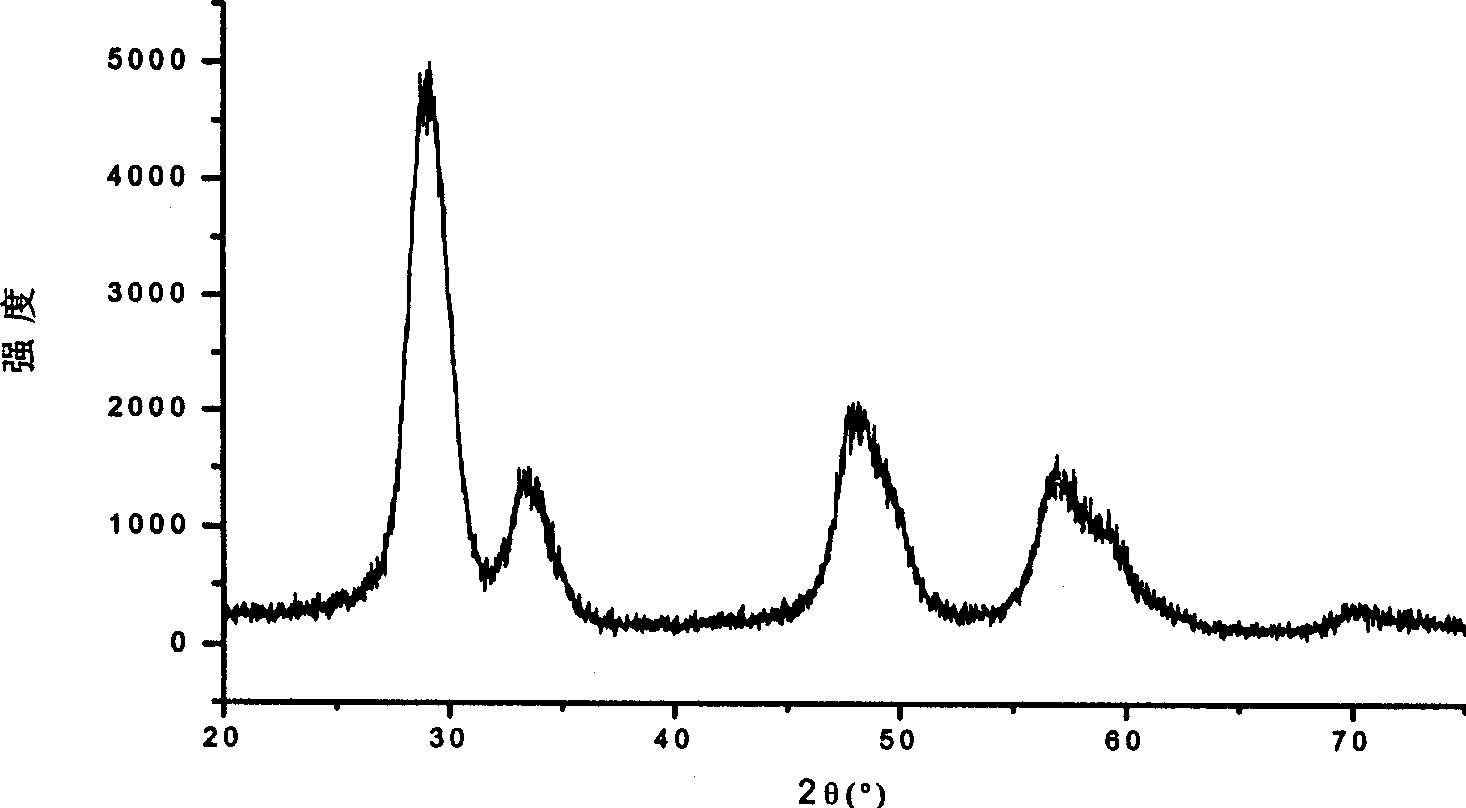

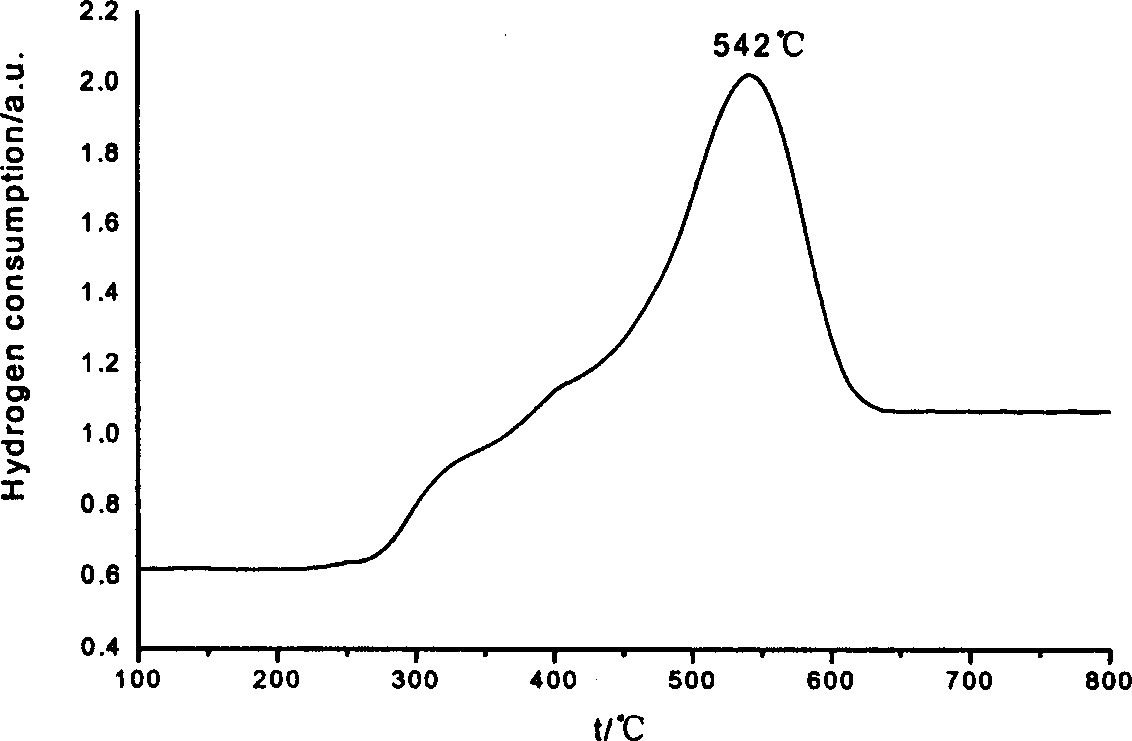

Embodiment 1

[0026] Take 24.8gZr(NO 3 ) 4 ·5H 2 O, 25.1gCe(NO 3 ) 3 ·6H 2 O and 100ml of deionized water are heated and dissolved to make solution (I), and 60ml of ammonia water is dissolved in 60ml of water to make solution (II). Put a little ammonia water at the bottom of the flask in advance, control the pH value at 9.5-10.5, and stir vigorously At the same time, solution (I) and solution (II) were added dropwise to the flask to form a purple precipitate, which was stirred at room temperature for 0.5-1 hour and then aged for 24 hours, and the precipitated hydroxide after static aging was suction-filtered and heated at 110°C After drying, bake at 550°C for 5 hours to obtain a single cerium-zirconium composite oxide with a specific surface area of 68.6m 2 / g, after calcination at 900℃ for 6 hours, the specific surface area is 21.4m 2 / g.

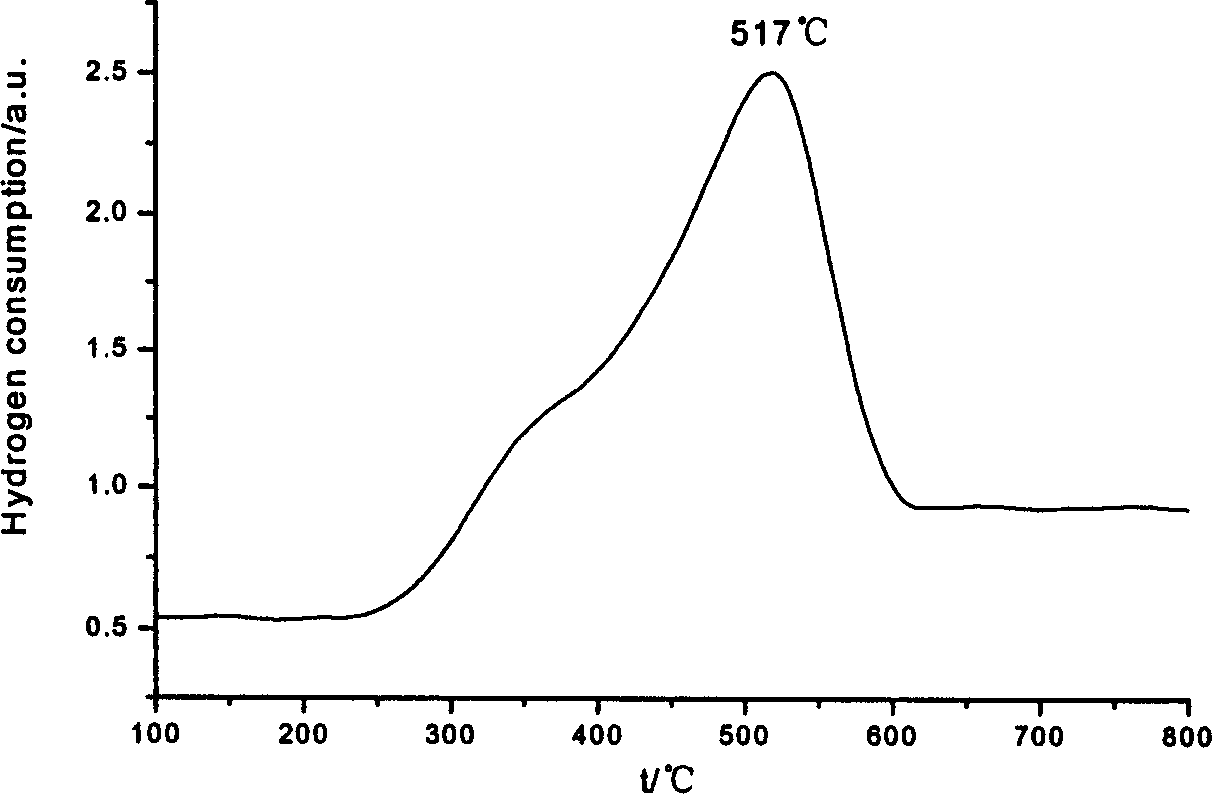

Embodiment 2

[0028] Take 24.8g Zr(NO 3 ) 4 ·5H 2 O, 25.1g Ce(NO 3 ) 3 ·6H 2O and 100ml deionized water are heated and dissolved to make solution (I), get 15ml hydrogen peroxide and 60ml ammonia water and dissolve in 60ml water to make solution (II), put a little ammonia water in advance at the bottom of the flask, control the pH value at 9.5-10.5, Stir vigorously and add solution (I) and solution (II) dropwise to the flask at the same time to form a yellow precipitate. Stir at room temperature for 0.5-1 hour and then age statically for 24 hours. Suction filter the precipitated hydroxide after static aging , after being dried at 110°C, and then calcined at 550°C for 5 hours, a single cerium-zirconium composite oxide can be obtained with a specific surface area of 107.4 m 2 / g, after calcination at 900℃ for 6 hours, the specific surface area is 32.2m 2 / g.

Embodiment 3

[0030] Take 24.8g Zr(NO 3 ) 4 ·5H 2 O, 25.1g Ce(NO 3 ) 3 ·6H 2 O, 4.8gLa(NO 3 ) 3 ·nH 2 O and 100ml deionized water are heated and dissolved to make solution (I), get 15ml hydrogen peroxide and 60ml ammonia water and dissolve in 60ml water to make solution (II), put a little ammonia water in advance at the bottom of the flask, control the pH value at 9.5-10.5, Add solution (I) and solution (II) dropwise under vigorous stirring to form a yellow precipitate, stir at room temperature for 0.5-1 hour and then age it statically for 24 hours, filter the precipitated hydroxide after static aging, and pass through 110 After drying at 550°C for 5 hours, cerium-zirconium-lanthanum composite oxide can be obtained with a specific surface area of 92.4m 2 / g, after calcination at 900℃ for 6 hours, the specific surface area is 38.2m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com