Oxygen storage material for the catalytic purification of car exhaust gas

A technology for catalytic purification and oxygen storage materials, applied in energy. It can solve problems such as the decrease of oxygen storage capacity, and achieve the effects of no decrease in oxygen storage capacity, high oxygen storage capacity, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Specific steps are as follows:

[0018] (1) The molar ratio is (Ce:Zr):Fe=1-x:x, where x=0.1~0.9, Ce:Zr=6:4; weigh 1.00~20.00g of Ce(NO 3 ) 3 .6H 2 O and stoichiometric Zr(NO 3 ) 4 .5H 2 O, add 1.00-20.00g of citric acid, and then add an appropriate amount of deionized water.

[0019] (2) Add 60-100 ml of an appropriate amount of absolute ethanol to the solution of (1) above, and stir for 4-5 hours.

[0020] (3) Stirring was stopped, the above solution was put into a water bath at 75° C., and the solution was evaporated for 4 hours to make the solution a yellow clear liquid.

[0021] (4) Add a few drops of concentrated nitric acid to the above solution, then put it in an oven at 120°C, and dry it for 12 hours to obtain a yellow spherical powder. (5) The powder was fired at 600°C for 5 hours to obtain superfine particles of cerium-zirconium-iron composite oxide (Ce 0.6 Zr 0.4 ) x Fe 1-x o 2 .

Embodiment 2

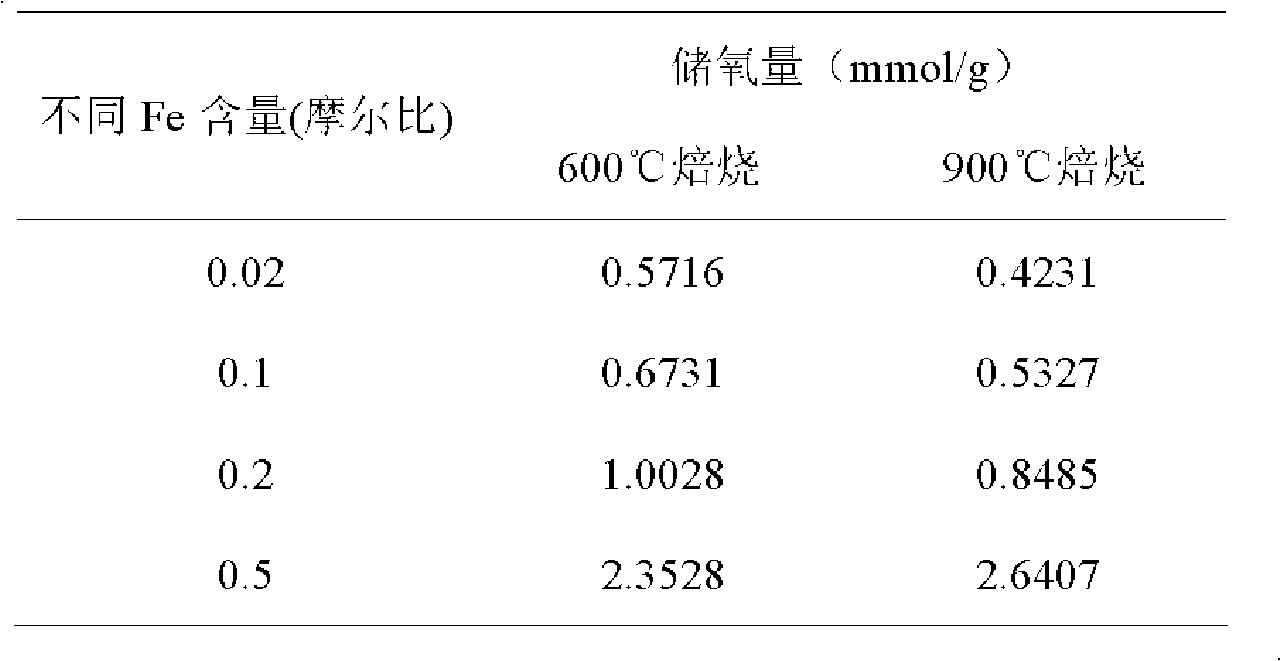

[0022] Embodiment 2: with (Ce 0.6 Zr 0.4 ) 1-x Fe x o 2 In x=0.02, 0.1, 0.2, 0.5 as an example, list their oxygen storage capacity as a comparison, see Table 1.

[0023] Table 1. (Ce 0.6 Zr 0.4 ) x Fe 1-x o 2 Oxygen Storage Capacity Comparison

[0024] Table 1. (Ce 0.6 Zr 0.4 ) x Fe 1-x o 2 Oxygen Storage Capacity Comparison

[0025]

[0026] It can be seen from Table 1 that the cerium-zirconium-iron composite oxide prepared by us, with the increase of iron content, not only the low-temperature oxygen storage capacity increases, but also the oxygen storage capacity does not decrease much after high-temperature calcination. When the addition amount of iron is 0.5, the oxygen storage capacity of the sample is higher than that of the low-temperature roasted one. This shows that the powder we prepared has high anti-aging performance at high temperature, and is suitable as an auxiliary agent for a three-way catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com