Nano-zirconia dispersion liquid, preparation method thereof, monomer dispersion liquid obtained based on nano-zirconia dispersion liquid and optical film

A nano-zirconia and dispersion technology, applied in optics, optical components, coatings, etc., can solve the problems of low boiling point of alcohol solvent, complicated preparation process, limitation of modification temperature, etc., and achieve high dispersion content, simple operation, good quality Effects of Modification Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add propylene glycol methyl ether (PGME) solvent to the zirconia aqueous solution, and after mixing evenly, add isooctanoic acid (the addition amount is 5% of the zirconium content), 3-(methacryloyloxy)propyltrimethyl Oxysilane (the addition amount is 10% of the zirconium content) is used to modify the zirconia particles, and then oily dispersion aid BYK-9076 (the addition amount is 5%) is added, and the water is removed by rotary evaporation to obtain nano-zirconia organic PGME type Dispersions.

[0045] In the nano-zirconia organic PGME type dispersion liquid, when the concentration of nano-zirconia is 45wt%, the refractive index is 1.475; when the concentration is 65%, the refractive index is 1.535; when the concentration is 75wt%, the refractive index is 1.565.

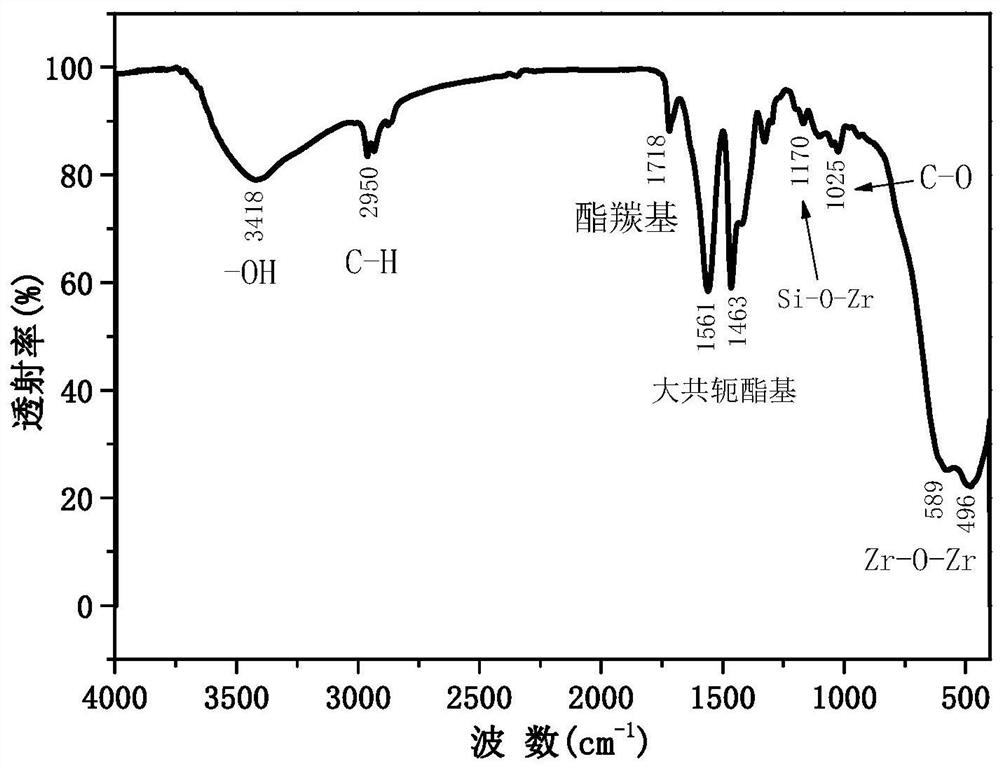

[0046] attached figure 1 Be the infrared spectrogram of embodiment 1, wherein 3418cm -1 The absorption peak is the characteristic absorption peak of the hydroxyl group on the surface of zirconia particles...

Embodiment 2

[0048] The preparation method is the same as in Example 1, the difference is that the amount of isooctanoic acid added is 3% of the zirconium content, the amount of 3-glycidyl etheroxypropyl trimethoxysilane is 5% of the zirconium content, and the oily dispersion aid The amount of the agent BYK-9076 is 10% of the zirconium content, and the nano-zirconia organic PGME type dispersion liquid is obtained.

[0049] In the nano-zirconia organic PGME type dispersion liquid, when the concentration of nano-zirconia is 45wt%, the refractive index is 1.470; when the concentration is 65%, the refractive index is 1.529; when the concentration is 75wt%, the refractive index is 1.558.

Embodiment 3

[0051] The preparation method is the same as in Example 1, except that the amount of isooctanoic acid added is 12% of the zirconium content, and the amount of modifier 3-(methacryloyloxy) propyltrimethoxysilane is 15% of the zirconium content , the amount of the oily dispersing aid BYK-9077 is 15% of the zirconium content, and the nano-zirconia organic PGME type dispersion liquid is obtained.

[0052] In the nano-zirconia organic PGME type dispersion liquid, when the concentration of nano-zirconia is 45wt%, the refractive index is 1.461; when the concentration is 65%, the refractive index is 1.522; when the concentration is 75wt%, the refractive index is 1.552.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com