Preparation method of banded graphene oxide reinforced nylon composite material

A technology of nylon composite materials and graphene, which is applied in the field of plastic materials, can solve the problems of poor dispersion of graphene and limited improvement of mechanical properties of nylon materials, and achieve the effect of improving mechanical properties, improving mechanical properties, and increasing dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

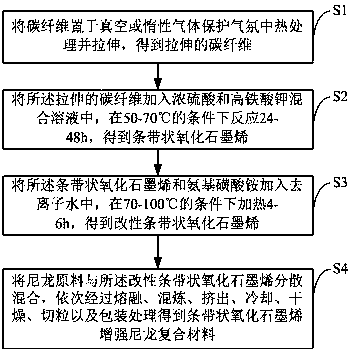

[0022] see figure 1 , figure 1 It is a flowchart of a preparation method of a strip-shaped graphene oxide reinforced nylon composite material of the present invention, as shown in the figure, it includes steps:

[0023] S1, placing the carbon fiber in a vacuum or an inert gas protective atmosphere for heat treatment and stretching to obtain a stretched carbon fiber;

[0024] S2, adding the stretched carbon fiber into a mixed solution of concentrated sulfuric acid and potassium ferrate, and reacting at 50-70°C for 24-48h to obtain striped graphene oxide;

[0025] S3, adding the strip-shaped graphene oxide and ammonium sulfamate into deionized water, and heating at 70-100° C. for 4-6 hours to obtain modified strip-shaped graphene oxide;

[0026] S4. Dispersing and mixing the nylon raw material and the modified strip-shaped graphene oxide, and sequentially melting, kneading, extruding, cooling, drying, pelletizing, and packaging to obtain a strip-shaped graphene oxide-reinforce...

Embodiment 1

[0042]Use Zhongfu Shenying SYT35 carbon fiber without surface treatment and without protective layer, with a carbon content of 95%, and place it in a vacuum at 2500°C for heat treatment for 4 hours, and stretch the heat-treated carbon fiber to 0.5% of its original size. Prepare a mixed solution of 100ml of concentrated sulfuric acid and 10g of potassium ferrate at a low temperature of 3°C, put the above stretched carbon fiber into the mixed solution, react at 50°C for 24 hours, and centrifuge, wash, and dry the reacted product to obtain Strip-shaped graphene oxide, add 100g of the above-mentioned strip-shaped graphene oxide and 10g of ammonium sulfamate into 1L of deionized water, heat at 70°C for 5h, and then undergo centrifugation, water washing, and drying to obtain modified strip-shaped graphene oxide. Graphene, then 100g nylon 66, 1g modified strip-shaped graphene oxide, dispersed and mixed, and then successively undergo remelting, kneading, extrusion, cooling, drying, pel...

Embodiment 2

[0045] Use Zhongfu Shenying SYT35 carbon fiber without surface treatment and without protective layer, with a carbon content of 97%, heat treatment in a vacuum at 2700°C for 5 hours, and stretch the heat-treated carbon fiber to 1% of its original size. Prepare a mixed solution of 100ml of concentrated sulfuric acid and 25g of potassium ferrate at a low temperature of 4°C, put the above stretched carbon fiber into the mixed solution, react at 60°C for 36 hours, and centrifuge, wash and dry the reacted product to obtain Strip-shaped graphene oxide, add 100g of the above-mentioned strip-shaped graphene oxide and 15g of ammonium sulfamate into 1L of deionized water, heat at 80°C for 5h, successively undergo centrifugation, water washing, and drying to obtain modified strip-shaped graphene oxide Graphene, then 100g nylon 66, 2.5g modified strip-shaped graphene oxide, dispersed and mixed, and then successively undergo remelting, kneading, extrusion, cooling, drying, pelletizing and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com