Flame-retardant bismaleimide resin composition and preparation method thereof

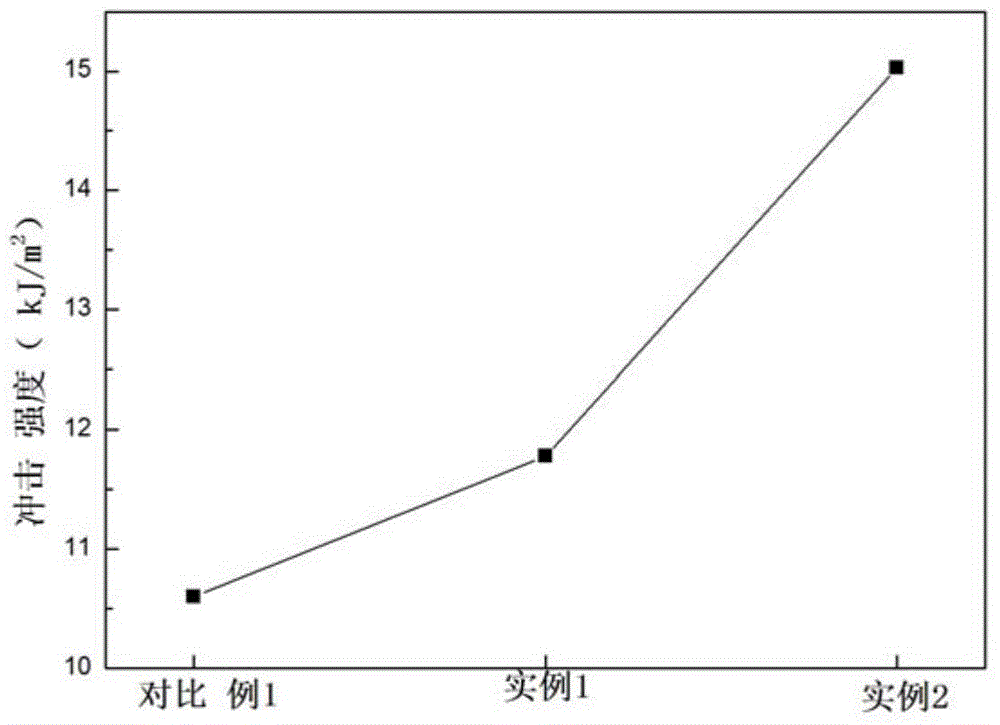

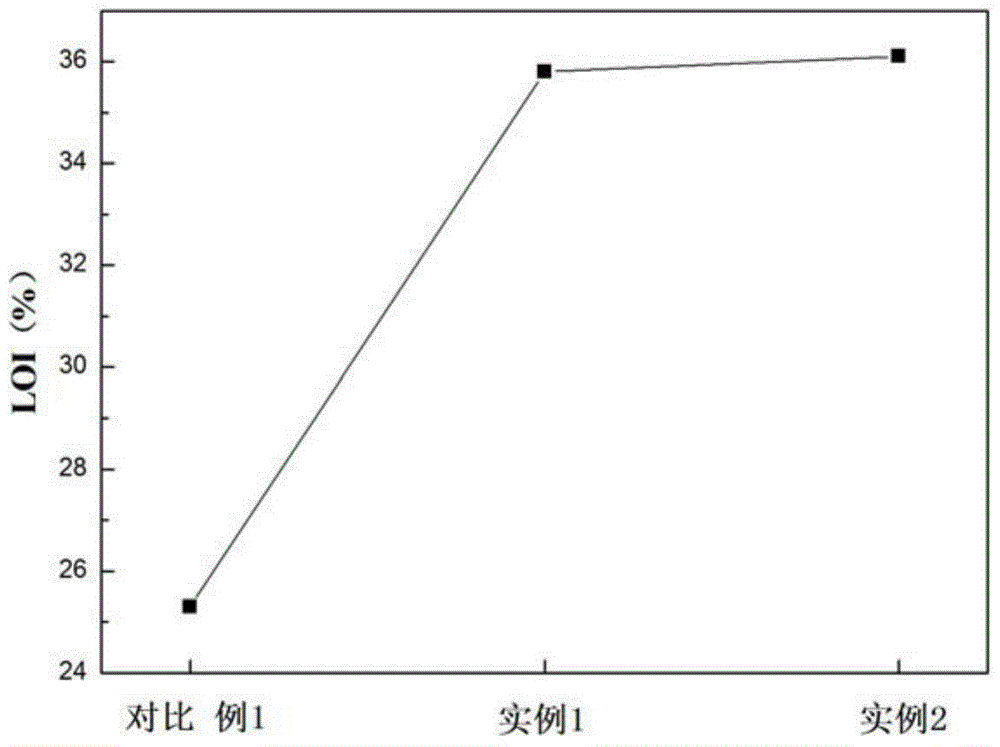

A technology of bismaleimide resin and maleimide resin, applied in the field of bismaleimide resin composition and its preparation, flame retardant resin composition and its preparation, can solve the mechanical properties of resin Damage, environmental pollution and other problems, to achieve the effect of flame retardant performance and thermal stability improvement, improve dispersion effect, impact performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

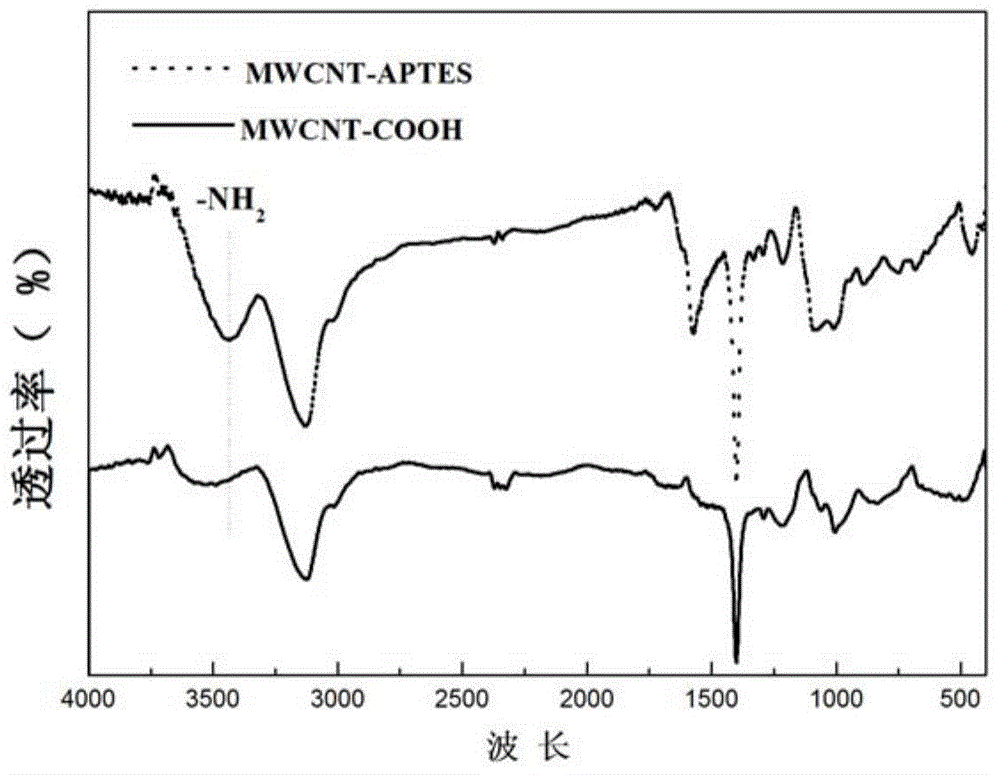

[0030] 1. Surface treatment of carbon nanotubes

[0031] (1) 0.5 parts of carbon nanotubes are refluxed with a mixture of concentrated sulfuric acid and concentrated nitric acid at a weight ratio of 3:1, and carboxyl and hydroxyl polar groups are grafted on the carbon nanotubes to obtain modified carbon nanotubes. Tube;

[0032] The process of the reflux treatment is as follows: Ultrasonic at 50°C and 60Hz for 1 hour, then reflux at 100°C for 2 hours; after acidification, wash with 20 times distilled water, and filter under reduced pressure with a microporous membrane until the filtrate pH value reaches 7;

[0033] (2) Aminating the modified carbon nanotubes obtained in step (1) with 2% ethanol solution of APTES to obtain modified carbon nanotubes grafted with amino groups;

[0034] The process of the amination treatment is as follows: absolute ethanol and deionized water are formulated into a solution with a volume ratio of 95:5, which is used as a solvent, and the acidifie...

Embodiment 2

[0044] 1. Surface treatment of carbon nanotubes

[0045] (1) Reflux the carbon nanotubes with a mixture of concentrated sulfuric acid and concentrated nitric acid in a weight ratio of 3:1, and graft carboxyl and hydroxyl polar groups on the carbon nanotubes to obtain modified carbon nanotubes;

[0046] The process of the reflux treatment is as follows: Ultrasonic at 50°C and 60Hz for 1 hour, then reflux at 100°C for 2 hours; after acidification, wash with 20 times distilled water, and filter under reduced pressure with a microporous membrane until the filtrate pH value reaches 7;

[0047] (2) Aminating the modified carbon nanotubes obtained in step (1) with 2% ethanol solution of APTES to obtain modified carbon nanotubes grafted with amino groups;

[0048] The process of the amination treatment is as follows: absolute ethanol and deionized water are formulated into a solution with a volume ratio of 95:5, which is used as a solvent, and the acidified carbon nanotubes are ultra...

Embodiment 3

[0056] 1. Surface treatment of carbon nanotubes

[0057] (1) Reflux the carbon nanotubes with a mixture of concentrated sulfuric acid and concentrated nitric acid in a weight ratio of 3:1, and graft carboxyl and hydroxyl polar groups on the carbon nanotubes to obtain modified carbon nanotubes;

[0058] The process of the reflux treatment is as follows: Ultrasonic at 50°C and 60Hz for 1 hour, then reflux at 100°C for 2 hours; after acidification, wash with 20 times distilled water, and filter under reduced pressure with a microporous membrane until the filtrate pH value reaches 7;

[0059] (2) Aminating the modified carbon nanotubes obtained in step (1) with 2% ethanol solution of APTES to obtain modified carbon nanotubes grafted with amino groups;

[0060] The process of the amination treatment is as follows: absolute ethanol and deionized water are formulated into a solution with a volume ratio of 95:5, which is used as a solvent, and the acidified carbon nanotubes are ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com