Preparing method of perfluoroalkylpolyether oil-based magnetofluid

A technology of perfluoropolyether oil and magnetic fluid, which is applied in the direction of magnetic liquid, organic material/organic magnetic material, etc., can solve the problems that the dispersion effect of magnetic fluid cannot be optimal, and the particles and carrier liquid cannot be dissolved together. Achieve the effect of improving the dispersion effect and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

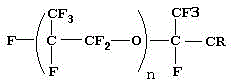

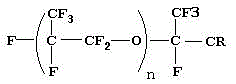

Method used

Image

Examples

Embodiment 1

[0026] FeCl 2 and ferric salt FeCl 3 According to the molar ratio of 1:2, add the alcohol emulsion prepared by 12g of the first surfactant (where R=OOH) at the reaction temperature of 80°C, then add the precipitant ammonia water 100ML, react for 1h, add hydrochloric acid to adjust the pH To 4, after alternate cleaning with distilled water and alcohol, remove the upper liquid under the action of a magnetic field, add 50mL transition solution C 5 h 2 f 10 , the magnetic particles are dissolved in the transition liquid, and then remove excess water and other impurities under the action of a magnetic field, take a small amount of liquid to measure the content of the magnetic particles, and finally add 20g of perfluoropolyether oil and the second surfactant R=OH, Perfluoropolyether oil-based magnetic fluid was obtained after heating and dispersing at 150°C.

Embodiment 2

[0028] FeCl 2 and ferric salt FeCl 3 According to the molar ratio of 1:2, add the alcohol emulsion prepared by 12g of the first surfactant (where R=OOH) at the reaction temperature of 80°C, then add the precipitant ammonia water 100ML, react for 1h, add hydrochloric acid to adjust the pH To 4, after alternate cleaning with distilled water and alcohol, remove the upper liquid under the action of a magnetic field, add 50mL transition solution C 4 f 9 OC 2 h 5 , the magnetic particles are dissolved in the transition liquid, and then excess water and other impurities are removed under the action of a magnetic field, a small amount of liquid is taken to measure the content of the magnetic particles, and finally 20g of perfluoropolyether oil and the second surfactant R=NH are added 2 , Perfluoropolyether oil-based magnetic fluid was obtained after heating and dispersing at 150°C.

Embodiment 3

[0030] FeCl 2 and ferric salt FeCl 3 According to the molar ratio of 1:2, add the alcohol emulsion prepared by 12g of the first surfactant (where R=OOH) at the reaction temperature of 80°C, then add the precipitant ammonia water 100ML, react for 1h, add hydrochloric acid to adjust the pH To 4, after alternate cleaning with distilled water and alcohol, remove the upper liquid under the action of a magnetic field, and add an appropriate transition solution C 6 f 14 , the magnetic particles are dissolved in the transition liquid, and then remove excess water and other impurities under the action of a magnetic field, take a small amount of liquid to measure the content of the magnetic particles, and finally add 20g of perfluoropolyether oil and the second surfactant R=CH 2 OH, perfluoropolyether oil-based magnetic fluid was prepared after heating and dispersing at 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com