High-efficiency and high-speed dispersing machine

A high-speed dispersing machine, high-efficiency technology, applied in the direction of mixers, mixer accessories, mixers with rotating containers, etc., can solve the problems of poor dispersion equipment and achieve the effect of improving the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

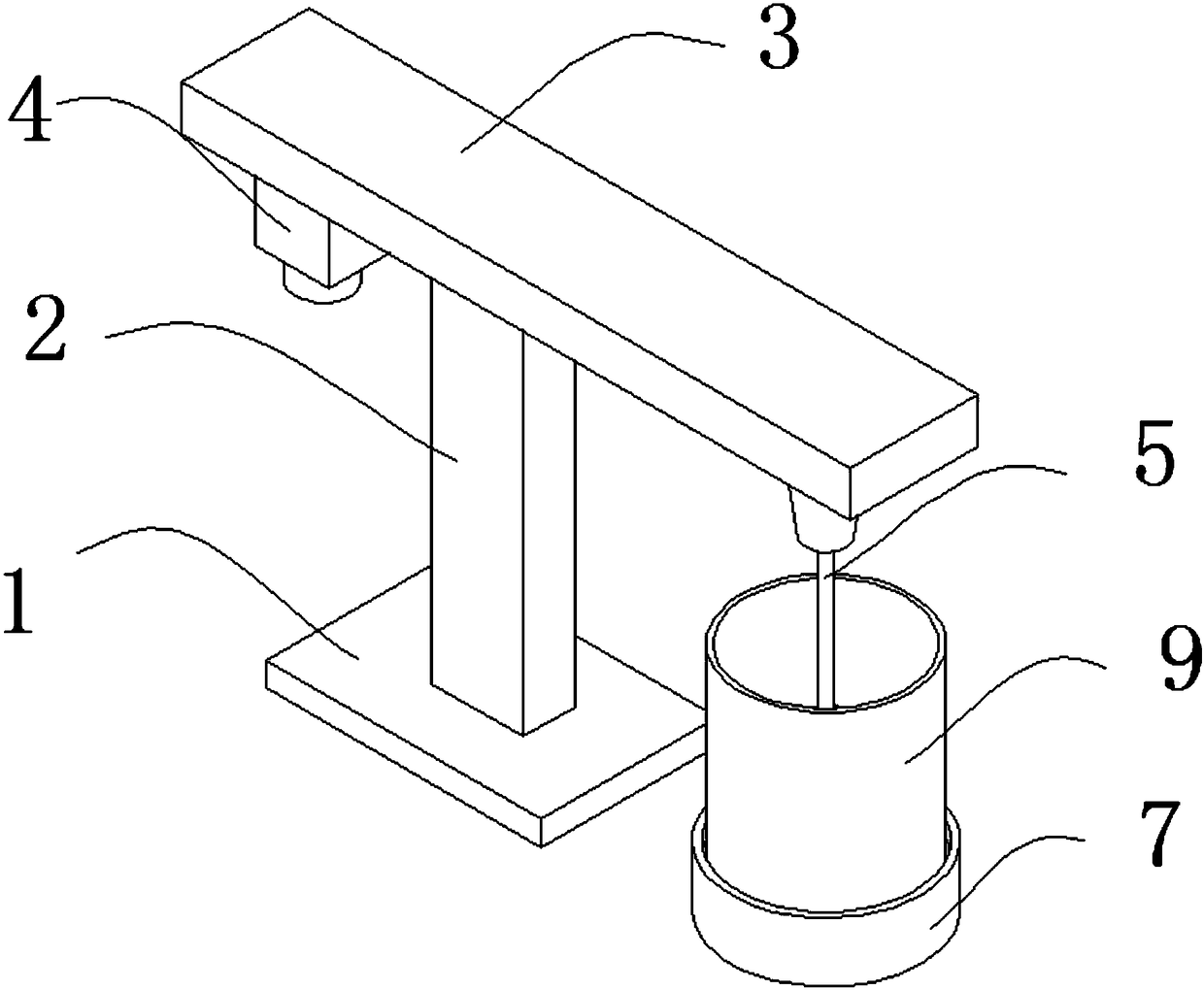

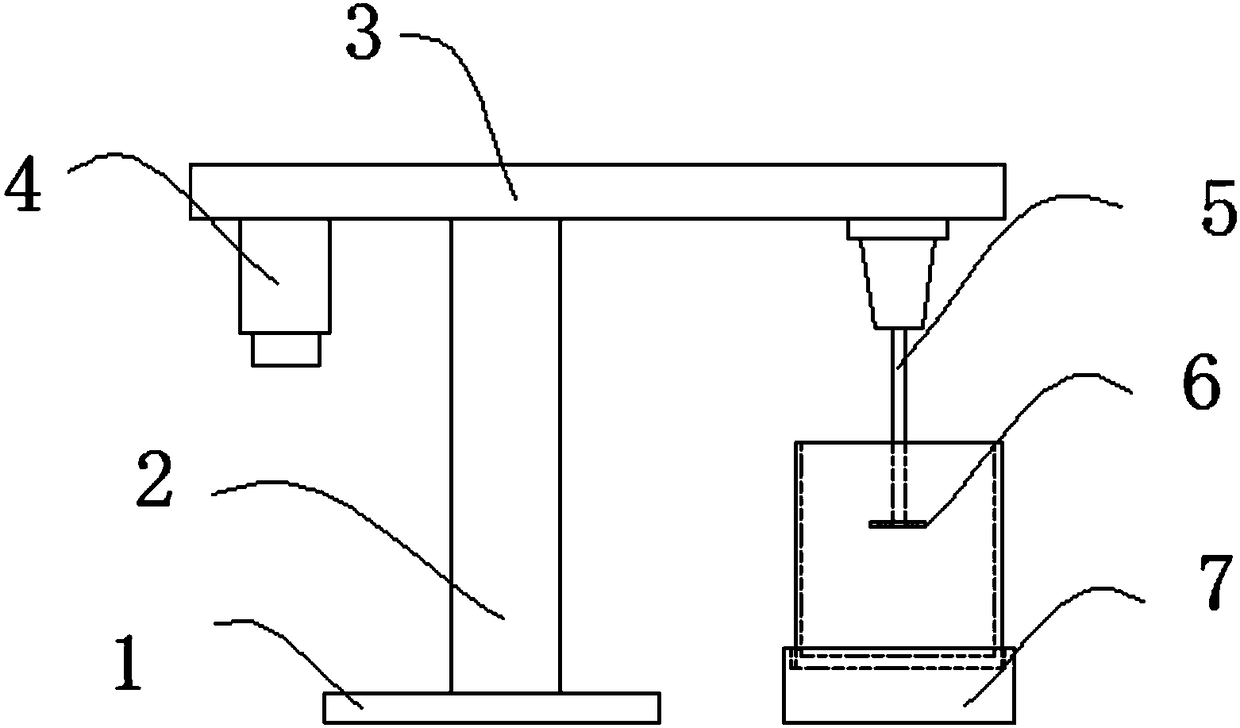

[0026] combined with Figure 1-Figure 4 , a high-efficiency high-speed dispersing machine of the present invention includes a base 1, a pillar 2, a horizontal frame 3, a first motor 4, a rotating shaft 5, a dispersion disc 6 and a belt transmission mechanism (not shown in the figure), and the bottom of the pillar 2 is fixed on On the base 1, the horizontal frame 3 is installed on the top of the pillar 2, the tops of the first motor 4 and the rotating shaft 5 are respectively arranged at both ends of the horizontal frame 3, the belt transmission mechanism is arranged in the horizontal frame 3, and the first motor 4 passes through the belt transmission mechanism. 4 is connected with the rotating shaft 5, and the dispersion disc 6 is fixed on the bottom of the rotating shaft 5;

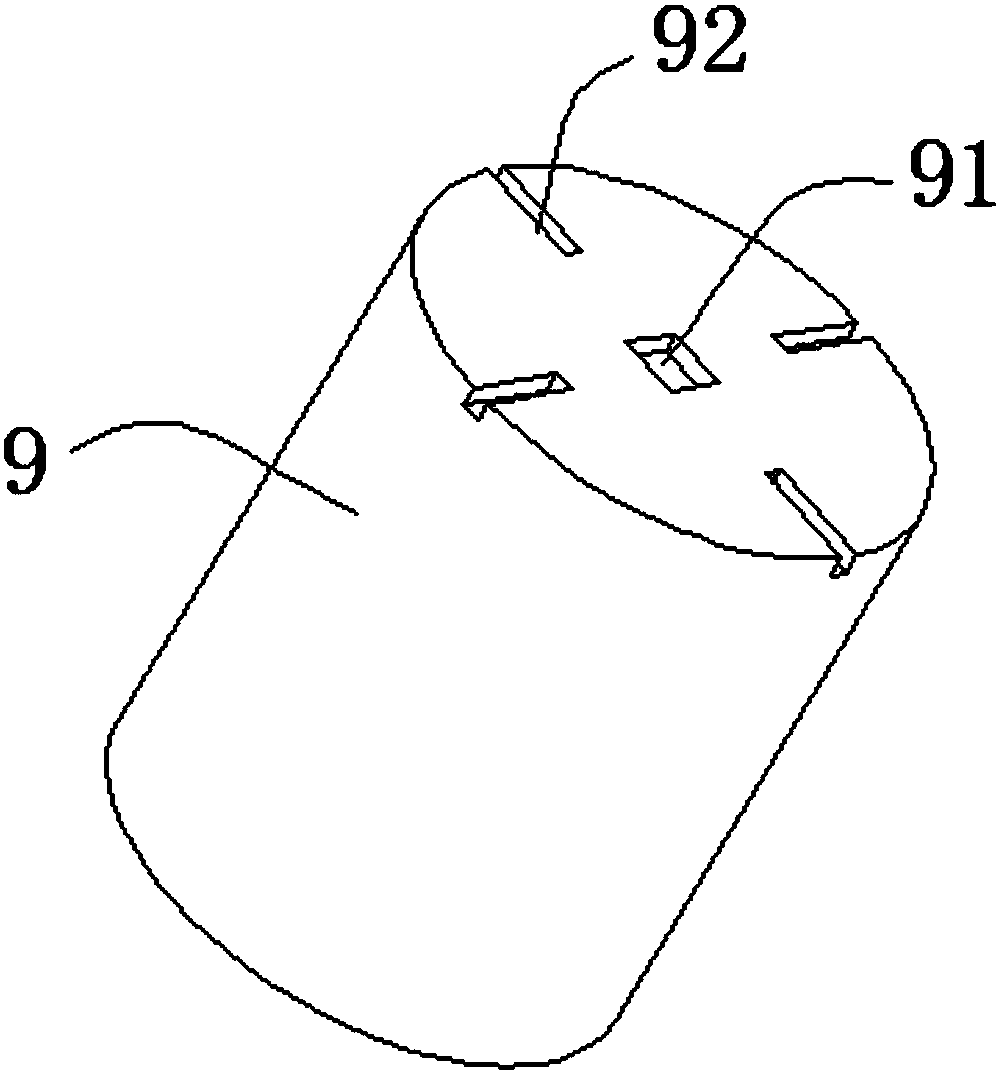

[0027] Also include a base 7, a second motor (not shown), a circular fixed disc 8 and a cylinder 9, the base 7 is arranged below the dispersion disc 6, and the second motor is installed in the base 7, T...

Embodiment 2

[0033] combined with Figure 1-Figure 6 , the difference from Embodiment 1 is that, further, a lifting device is provided under the base 7, and the lifting device includes a shearing lifting frame 10, an electric push rod 11 and a plug joint 12, and the shearing type One end of the bottom of the lifting frame 10 is connected to the electric push rod 11 , and the other end is connected to the plug joint 12 , and the top of the shearing type lifting frame 10 is connected to the bottom of the base 7 .

[0034] Further, a sunken groove 13 is opened under the base 7 , and the lifting device is arranged in the sunken groove 13 .

[0035] Further, the dispersing disc 6 includes at least two, which are respectively fixed on the rotating shaft 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com