Improved concrete prefabricated slab

A technology for concrete and prefabricated panels, applied in the direction of hydraulic material layered products, building components, layered products, etc., can solve problems such as plate cracking, avoid cracking, high static slurry flow rate, and improve cohesion and the effect of workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

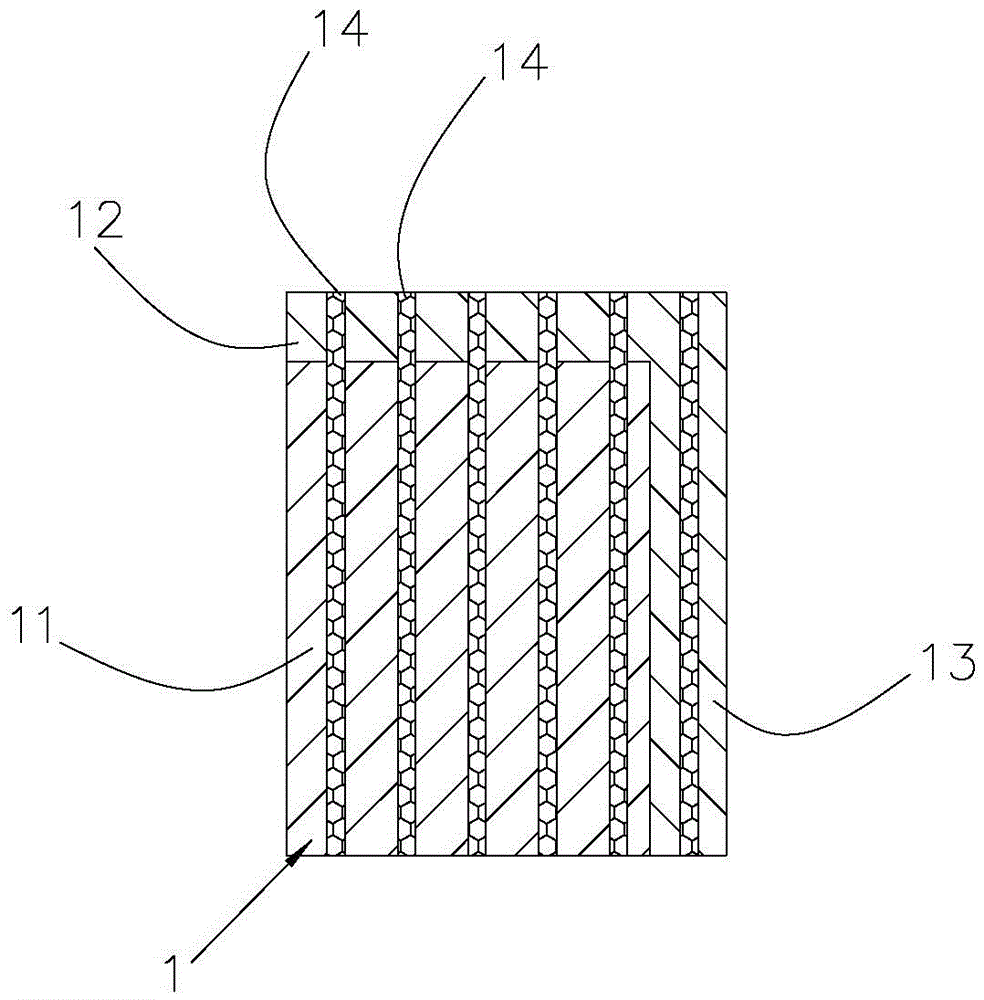

[0051] In this embodiment, the first fiber concrete part 12 and the first fiber concrete part 13 are composed of the following components in parts by weight: 40 parts of cement, 48 parts of sand, 70 parts of gravel, 5 parts of fly ash, and 16 parts of water , 2 parts of slag, 0.04 part of basalt fiber, 0.1 part of polypropylene fiber, 0.1 part of steel fiber, and 0.5 part of water reducing agent.

[0052] In this embodiment, the polypropylene fiber has an equivalent diameter of 400 μm, an aspect ratio of 55, a tensile strength greater than 500 MPa, and an elastic modulus of 7 GPa. The steel fiber has a diameter of 563 μm, an aspect ratio of 65, a tensile strength greater than 700 MPa, and an elastic modulus of 190 GPa.

[0053] In this example, the water reducer is prepared from the following molar parts of raw materials according to the following preparation method: 1 part of polyethylene glycol monomethyl ether acrylate, 2-acrylamido-2-methylpropanesulfonate sodium 1 part, ...

Embodiment 3

[0057] In this embodiment, the first fiber concrete part 12 and the first fiber concrete part 13 are composed of the following components in parts by weight: 45 parts of cement, 42 parts of sand, 80 parts of gravel, 2 parts of fly ash, and 20 parts of water , 1 part of slag, 0.08 part of basalt fiber, 0.05 part of polypropylene fiber, 0.2 part of steel fiber, and 0.3 part of water reducing agent.

[0058] In this embodiment, the polypropylene fiber has an equivalent diameter of 500 μm, an aspect ratio of 62, a tensile strength greater than 500 MPa, and an elastic modulus of 7.6 GPa. The steel fiber has a diameter of 550 μm, an aspect ratio of 65, a tensile strength greater than 700 MPa, and an elastic modulus of 240 GPa.

[0059] In this embodiment, the preparation method of the water reducing agent comprises the following steps: in molar parts, 1.5 parts of polyethylene glycol monomethyl ether acrylate, 1.5 parts of sodium 2-acrylamido-2-methylpropanesulfonate , 4 parts of m...

Embodiment 4

[0063]In this embodiment, the first fiber concrete part 12 and the second fiber concrete part 13 are composed of the following components by weight: 42 parts of cement, 42 parts of sand, 70 parts of gravel, 3 parts of fly ash, and 19 parts of water , 2 parts of slag, 0.06 part of basalt fiber, 0.07 part of polypropylene fiber, 0.12 part of steel fiber, and 0.4 part of water reducing agent.

[0064] In this embodiment, the polypropylene fiber has an equivalent diameter of 484 μm, an aspect ratio of 65, a tensile strength greater than 500 MPa, and an elastic modulus of 7.3 GPa. The steel fiber has a diameter of 600 μm, an aspect ratio of 62, a tensile strength greater than 700 MPa, and an elastic modulus of 233 GPa.

[0065] In this embodiment, the preparation method of the water reducing agent comprises the following steps: in molar parts, 1.3 parts of polyethylene glycol monomethyl ether acrylate, 1.4 parts of sodium 2-acrylamido-2-methylpropanesulfonate , 3.2 parts of methac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com