Squeezing drying granulating machine and adjustable mouth mold device thereof

A granulator and adjustable technology, which is applied in the field of squeeze-drying granulator and its adjustable die device, can solve the problems of different water content, increased use cost of customers, large difference in physical properties, etc., so as to change production capacity and save money. Use cost and the effect of meeting elastic demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

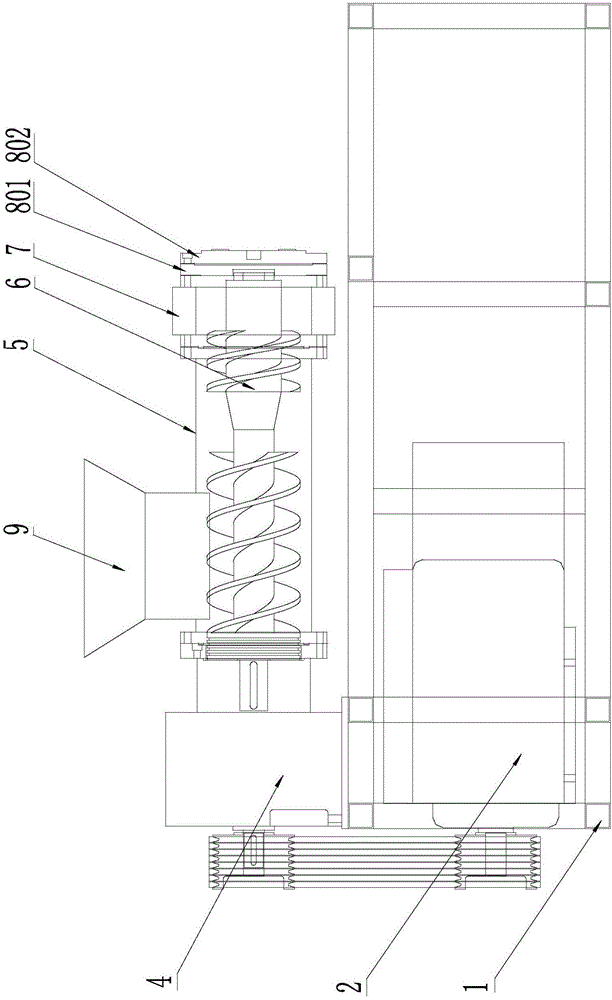

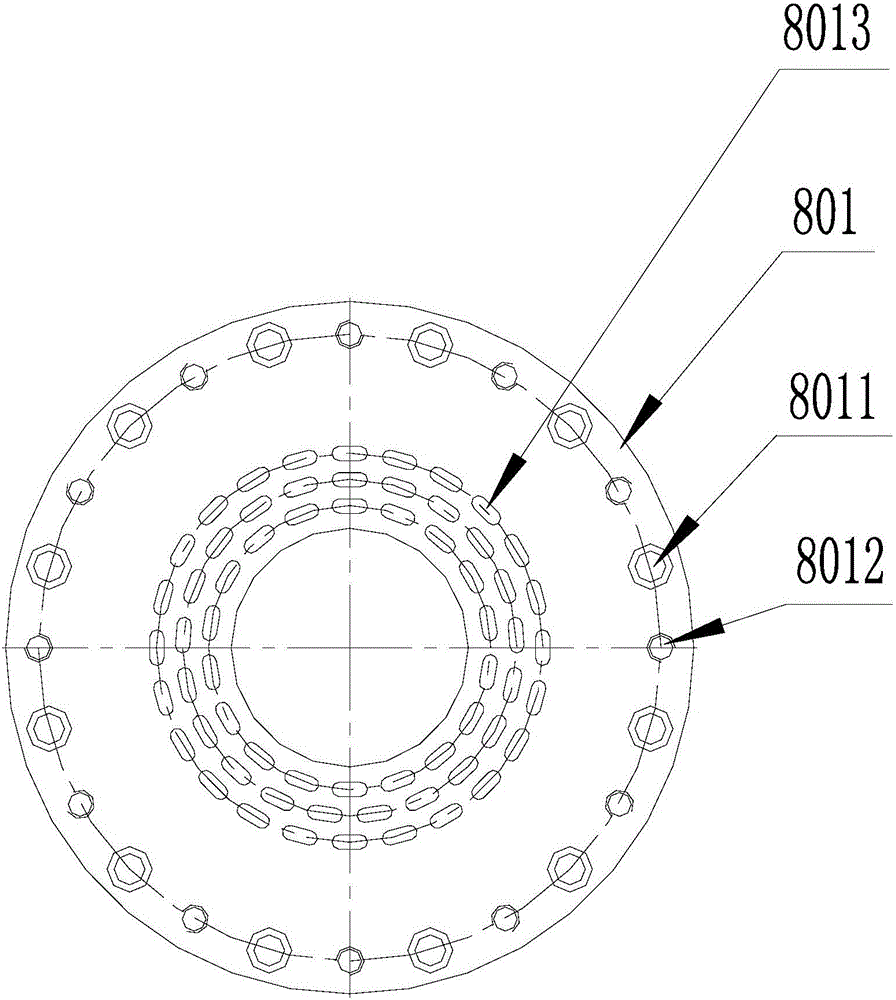

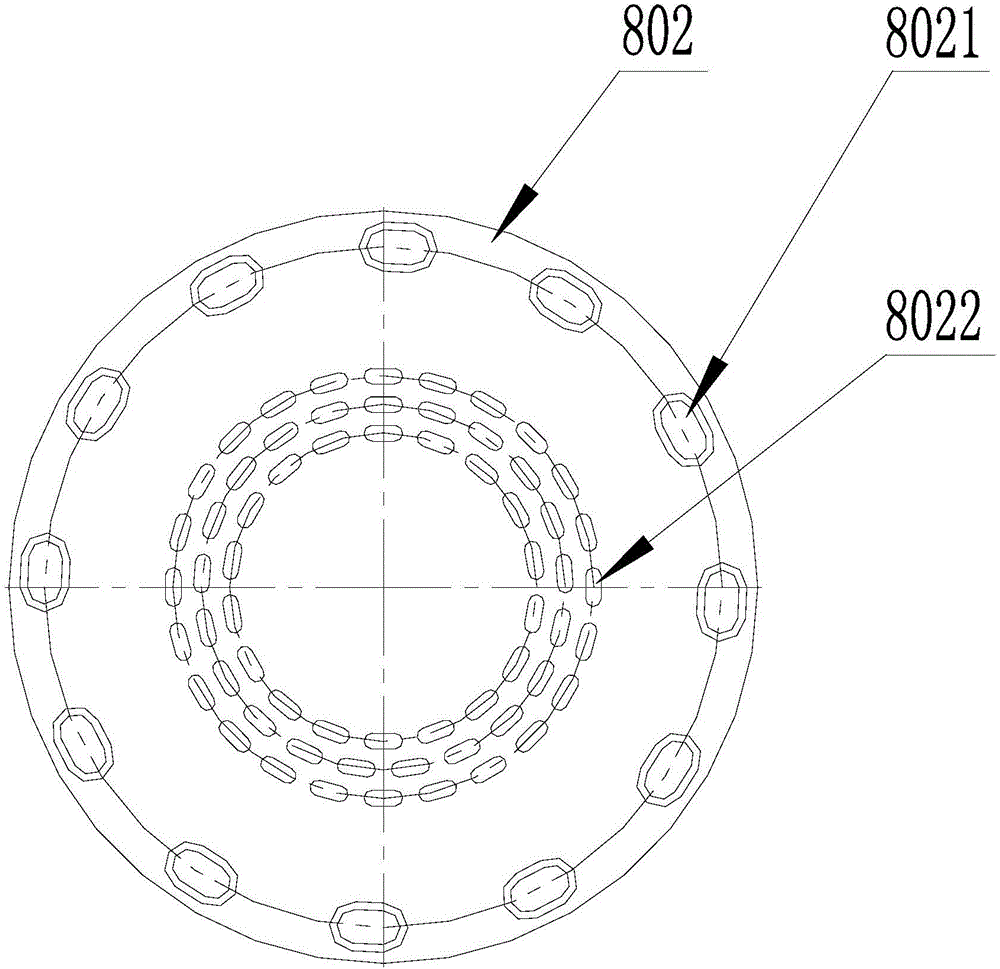

[0022] Such as figure 1 , figure 2 , image 3 As shown, a squeeze granulator includes a frame 1; a motor 2 arranged on the frame 1; a gear box 4 driven by the motor 2 on the frame 1; a machine barrel arranged at the output end of the gear box 4 5; the screw rod 6 that is installed inside the machine barrel 5 and connected with the output end of the reduction box 4; the heating device 7 that is arranged on the head of the machine barrel 5; the feed port 9 that is arranged on the machine barrel 5; A die one 801 connected to each other; a die two 802 connected to the die one 801; the die one 801 is provided with N counterbores 8011; N threaded holes 8012; said die one 801 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com