Improved type extrusion device for plastic bottles

A technology of extrusion device and plastic bottle, which is applied in punching machine, press machine, manufacturing tool, etc., can solve the problems that waste plastic bottles cannot be squeezed well, improve the labor intensity of operators, etc., and achieve good extrusion treatment. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Hereinafter, the present invention will be further described with reference to the drawings and specific implementations:

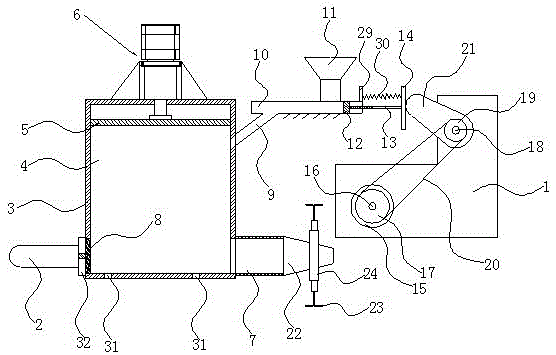

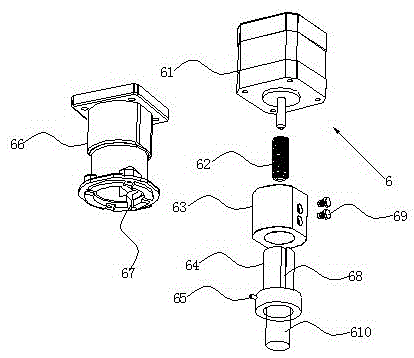

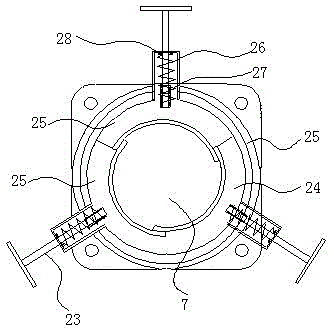

[0022] Such as Figure 1-3 Shown is an improved plastic bottle squeezing device of the present invention, including a frame 1, a cylinder 2, a box 3 with a chamber 4, and an squeezing device that is located in the chamber 4 and can move up and down relative to it. The pressing plate 5, a pushing device 6 for pushing the extrusion plate 5 to move up and down, a discharge tube 7 installed on the bottom side wall of the box 3, and a second part for pushing the material in the chamber 4 to the discharge tube 7 A push plate 8, the piston rod of the cylinder 2 is connected with the first push plate 8, a feed tube 9 is installed on the top side wall of the box 3, and a hollow tube 10 is connected to the feed tube 9 , The hollow tube 10 is connected with a hopper 11, the hollow tube 10 is provided with a second push plate 12 that can move left and right rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com