Waste recovery mechanism of plate cutting device

A cutting device and waste recycling technology, applied in the field of sheet metal processing, can solve the problems of affecting recycling efficiency, splashing, unsafe operation, etc., and achieve the effect of reducing space occupation, improving extrusion effect, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

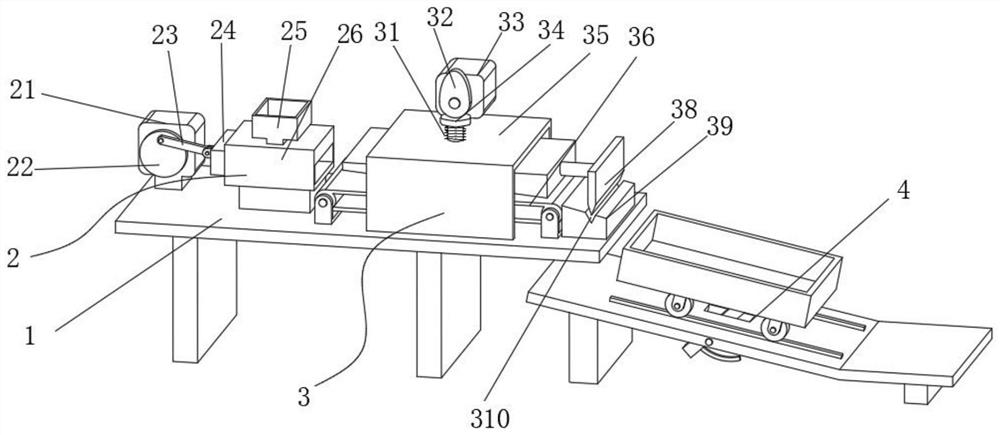

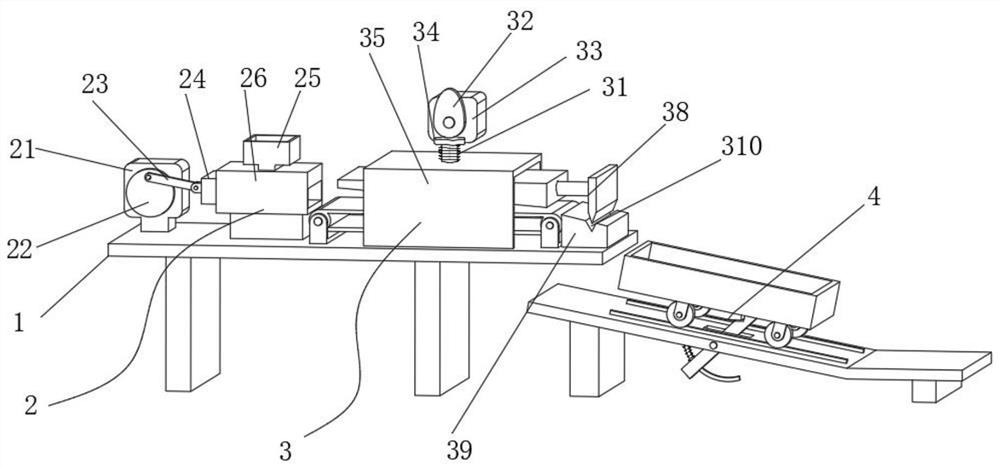

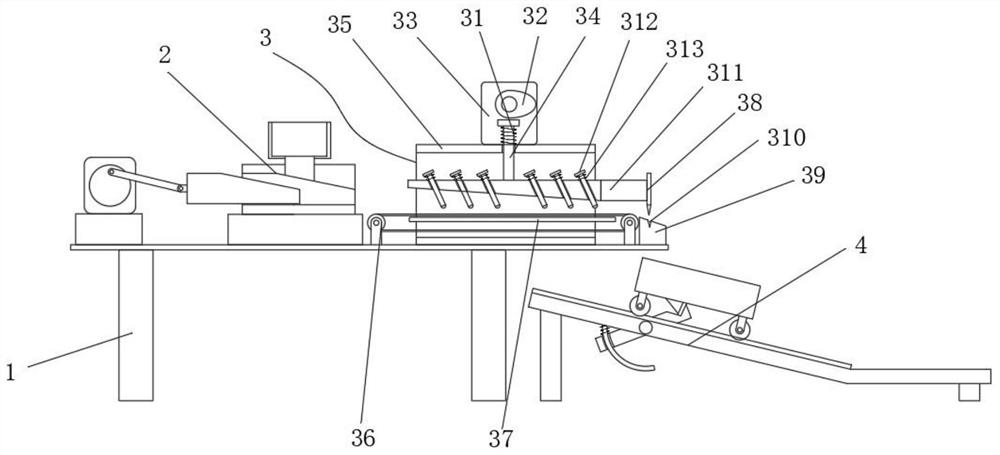

[0026] As an embodiment of the present invention, the extruding and cutting assembly 3 includes a vibrating spring 31, a cam 32, a cam motor 33, a vibrating rod 34, a vibrating box 35, a conveyor belt 36, a support plate 37, a cutting knife 38, and a cutting seat 39 , knife groove 310, extruding plate 311, push rod 312 and back-moving spring 313, the inside of the top side box wall of vibration box 35 is vertically worn with vibration rod 34, and the top of vibration rod 34 is set with vibration spring 31, vibration rod 34 Extrusion plate 311 is welded at the bottom of the bottom, cam motor 33 is installed on the top side of vibrating box 35 by bolts, cam 32 is installed on the rotating shaft of cam motor 33, and conveyor belt 36 is erected on the top side of support frame 1, The cutting knife 38 is welded on one side of the extrusion plate 311, the cutting seat 39 is welded on the top side of the support frame 1, the top side of the cutting seat 39 is provided with a knife gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com