Spray washing machine

A washing machine and spray hole technology, applied in other washing machines, washing devices, textiles and paper making, etc., to achieve the effect of improving washing efficiency, improving drainage smoothness, and increasing drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

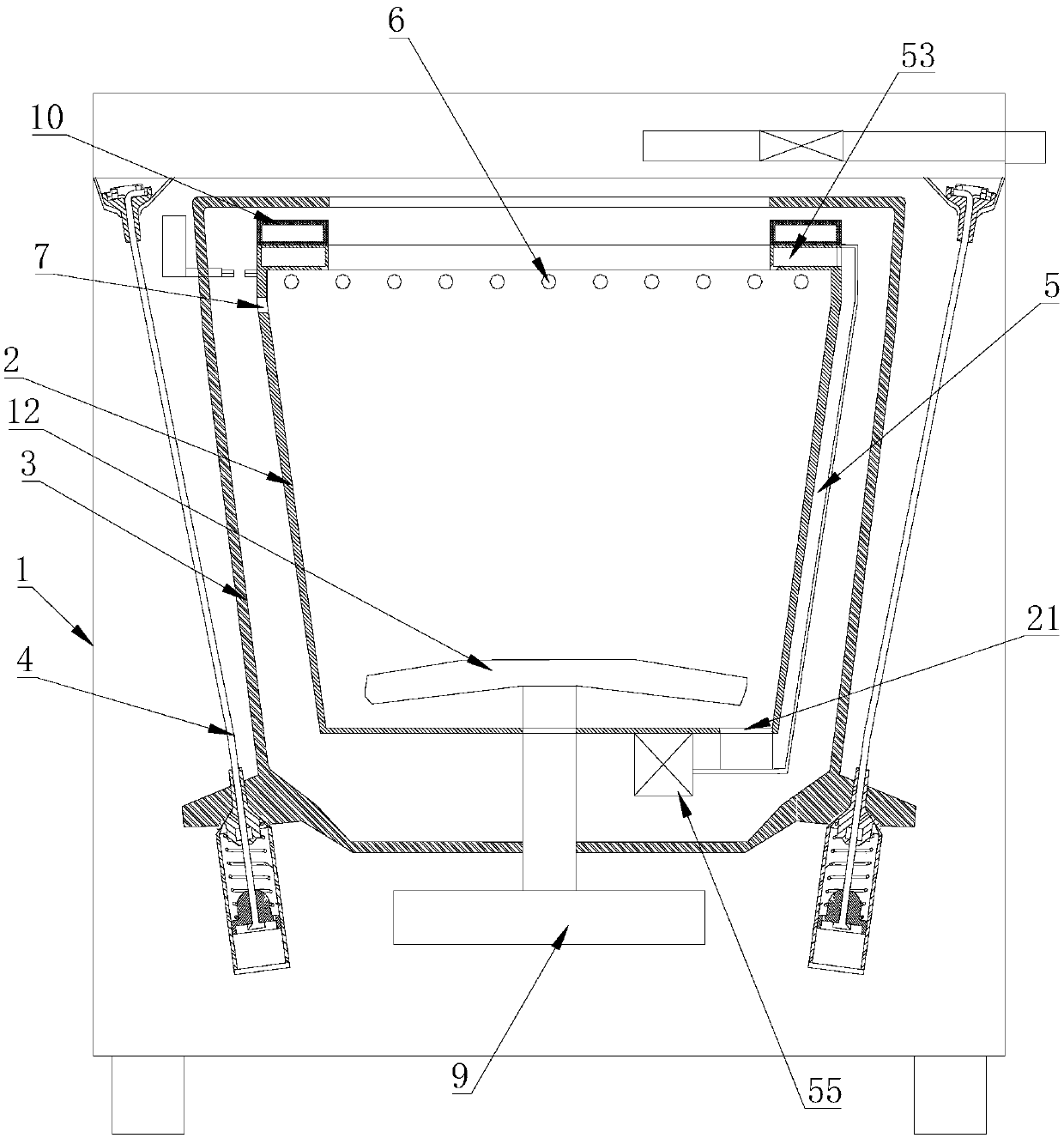

[0036] like figure 1 As shown, in this embodiment, the non-porous inner barrel 2 is a barrel-shaped structure with an open top and the axis is vertically arranged. The non-porous inner barrel 2 is a tapered barrel whose barrel diameter gradually expands from bottom to top. The dehydration holes 6 arranged at intervals are arranged in a circle. By setting the non-porous inner tub as a tapered tub whose diameter increases toward the direction of the dehydration hole, and setting a dehydration hole on the top of the non-porous inner tub, the remaining washing water in the tub or the water separated from the clothes by drying During the high-speed rotation of the non-porous inner tub, it is affected by the centrifugal force and flows along the tapered tub wall to the dehydration port until the non-porous inner tub is discharged from the dehydration port, thereby realizing the residual water in the washing machine drainage process and / or the separation from the clothes during the d...

Embodiment 2

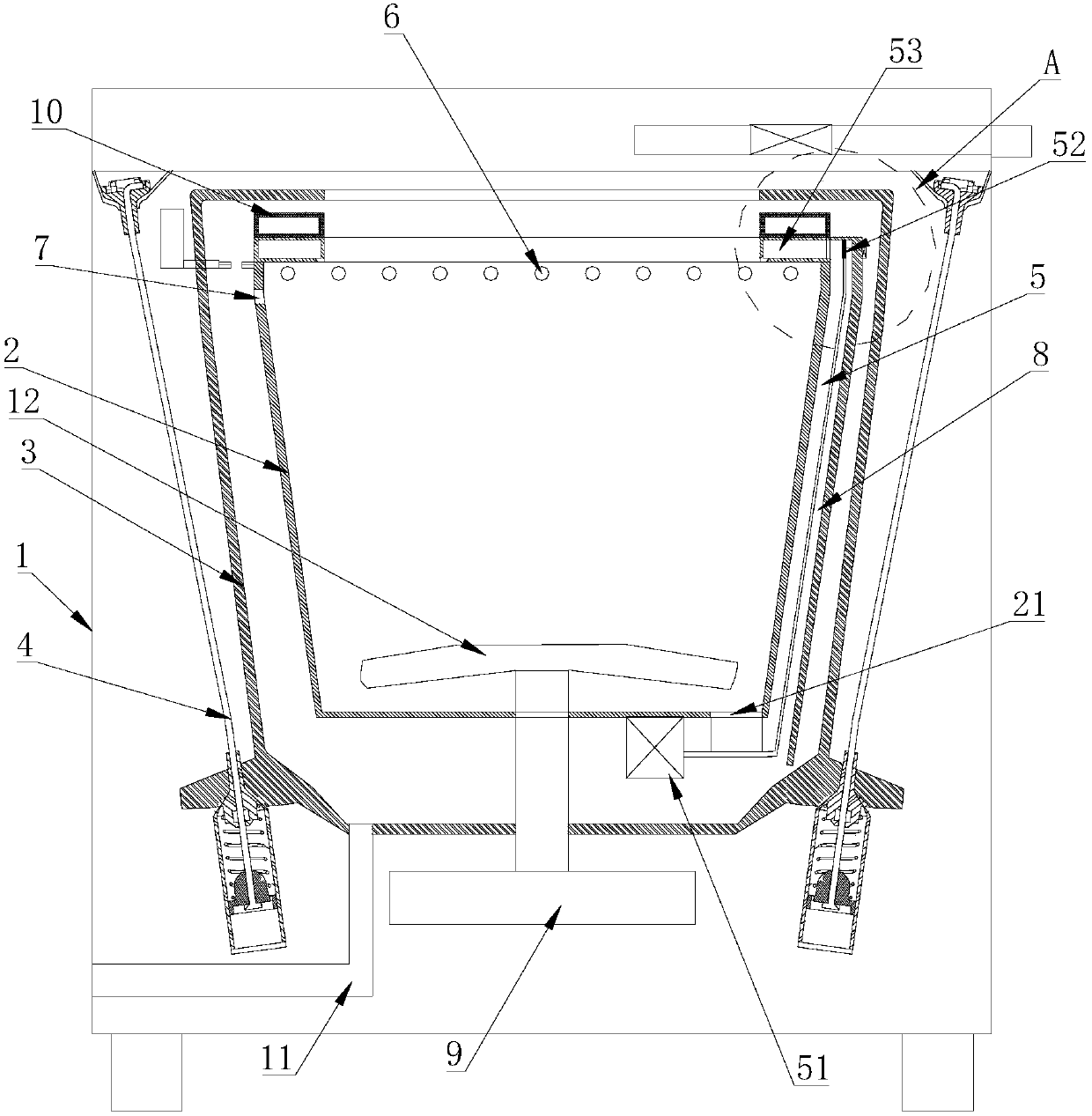

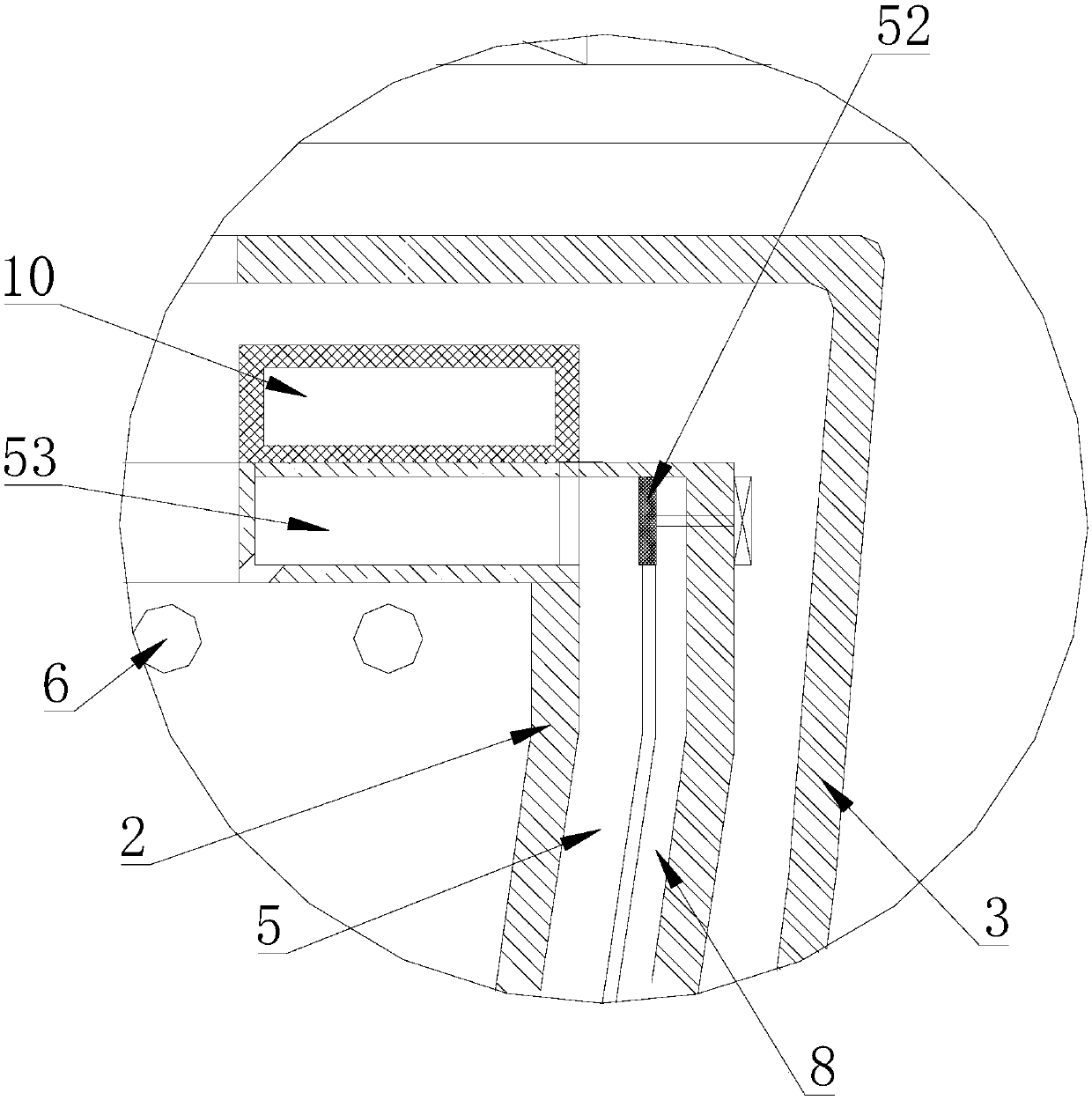

[0045] Based on the first embodiment above, this embodiment also has the following technical features: Figure 2 to Figure 4 As shown, in this embodiment, the non-porous inner barrel 2 is also provided with a drainage channel 8 extending from top to bottom, and the top of the drainage channel 8 is connected to the top of the circulation channel 5 through a control valve. The lower end of the channel 8 is set lower than the lower end of the circulation flow channel 5 .

[0046] By setting a controllable on-off drainage channel connected to the circulation flow channel on the non-porous inner tub, the washing water in the non-porous inner tub can be discharged along the circulation channel and the drainage channel through the action of the pump when the washing machine drains water. , to achieve the purpose of smoothly draining the washing water in the non-porous inner bucket.

[0047] In this embodiment, the top of the circulation channel 5 communicates with the interior of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com