Washing method of agitatory washer and its washer

A washing machine and stirring technology, applied in the field of washing machines, can solve the problems of poor washing effect and low washing ratio, and achieve the effects of improving washing ratio, reducing clothes entanglement, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Referring to Fig. 8, during washing, in order to improve the effect of "hand rubbing", the washing method of the present invention is: when washing, the inner barrel and the high wave wheel (agitator) are all driven by power, and rotate in opposite directions for washing.

[0021] The rotation is intermittent rotation, that is, it rotates according to a certain turn-to-stop ratio.

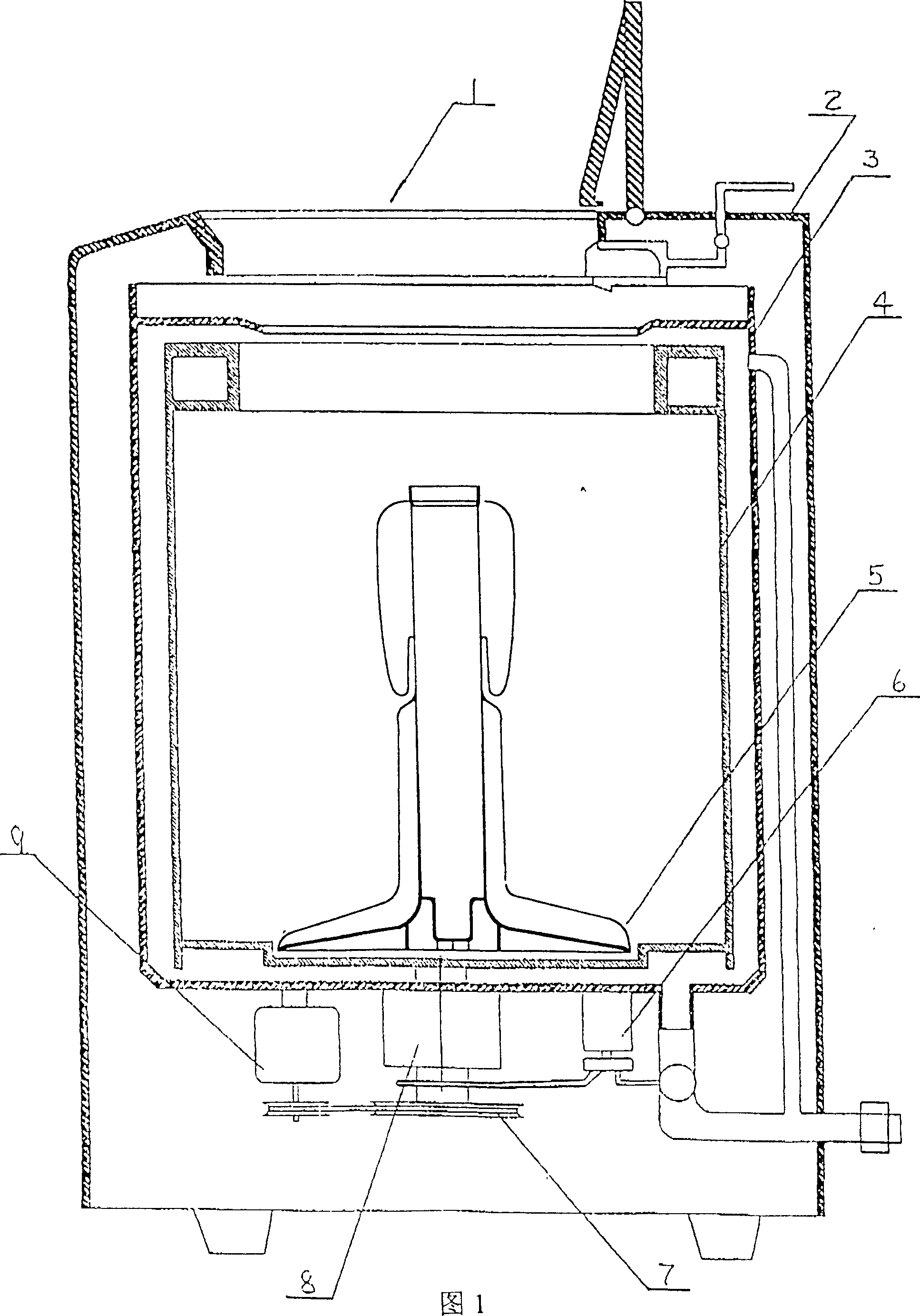

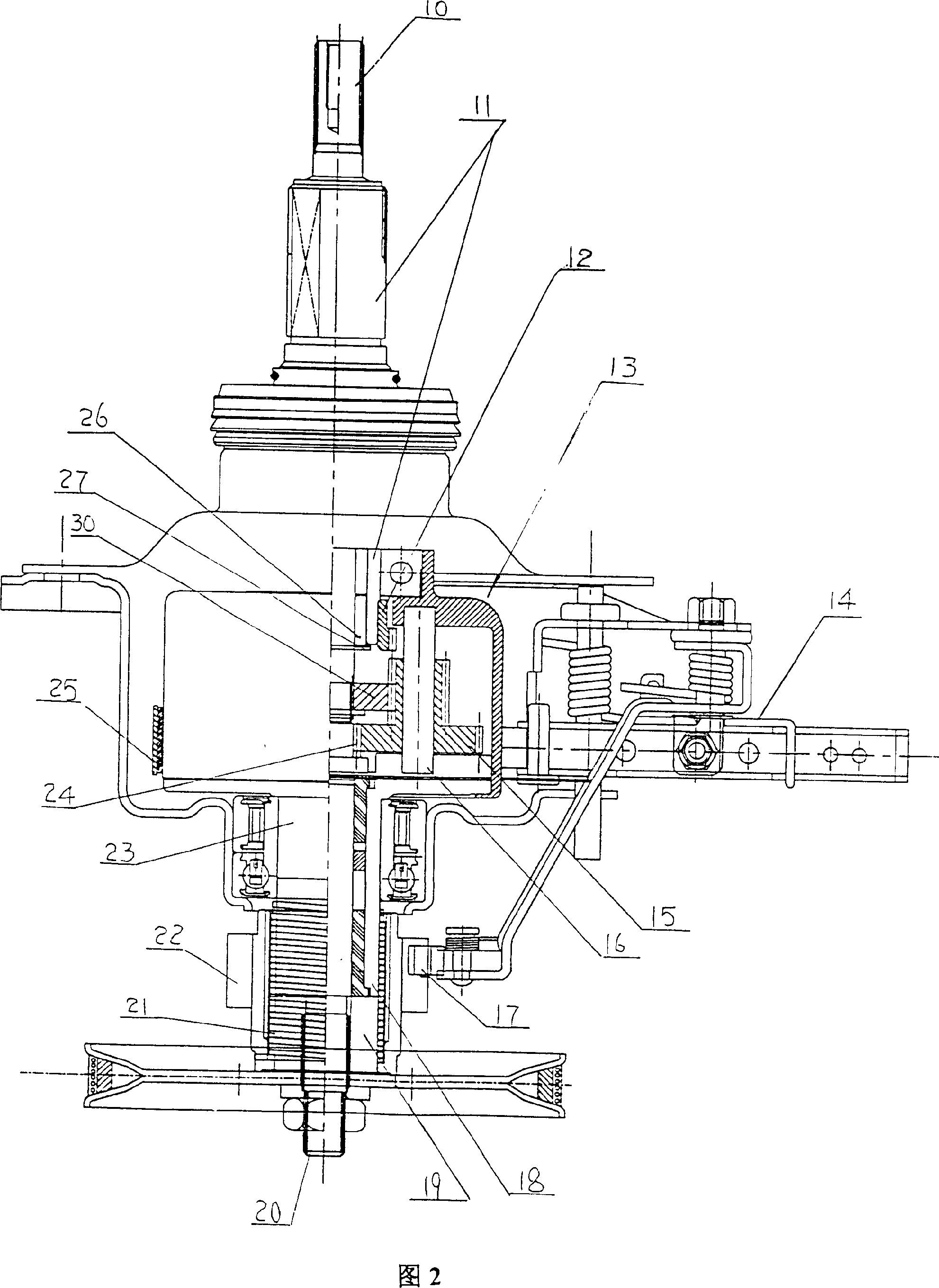

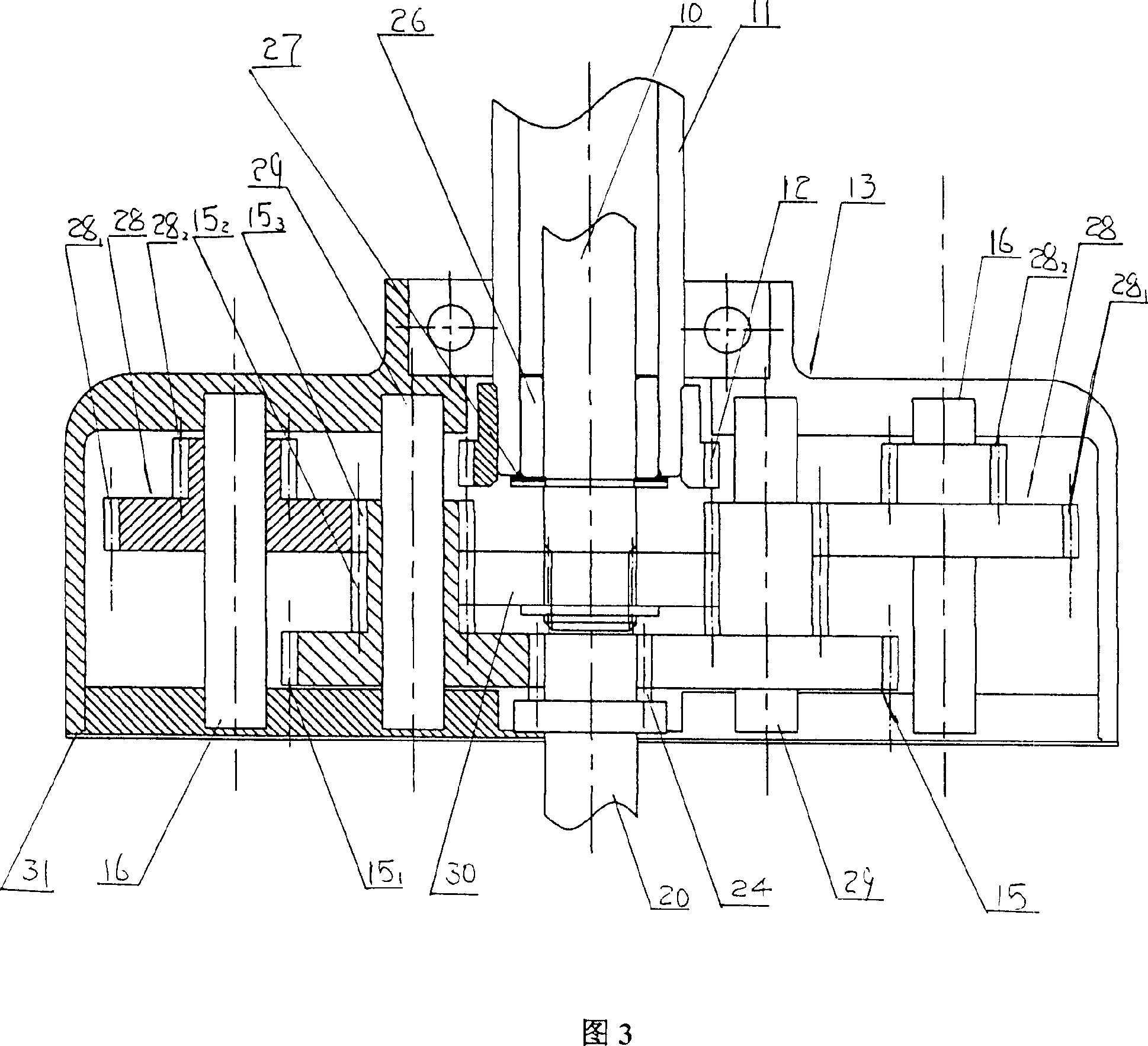

[0022] Referring to Fig. 1-Fig. 7, the whole washing machine is represented by mark 1, the transmission mechanism is represented by mark 8, and the gear box is represented by mark 13. In order to broaden the application range of the two-way power washing machine, the design concept of the present invention is: the agitator used is the high wave wheel 5, that is, the two-way power washing is applied to the agitation washing machine.

[0023] In order to achieve the purpose of the inner tub 4 rotating oppositely with the high wave wheel 5 under the drive of power, the present invention makes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com