Water flow controller for water spraying tool

A technology of water flow control and tools, which is applied in the direction of spraying devices, spraying devices, etc., can solve the problems of high strength, large flow rate, and high sealing requirements of water flow control devices, so as to achieve good sealing effect, increase water flow intensity, and improve water flow control effect and the effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

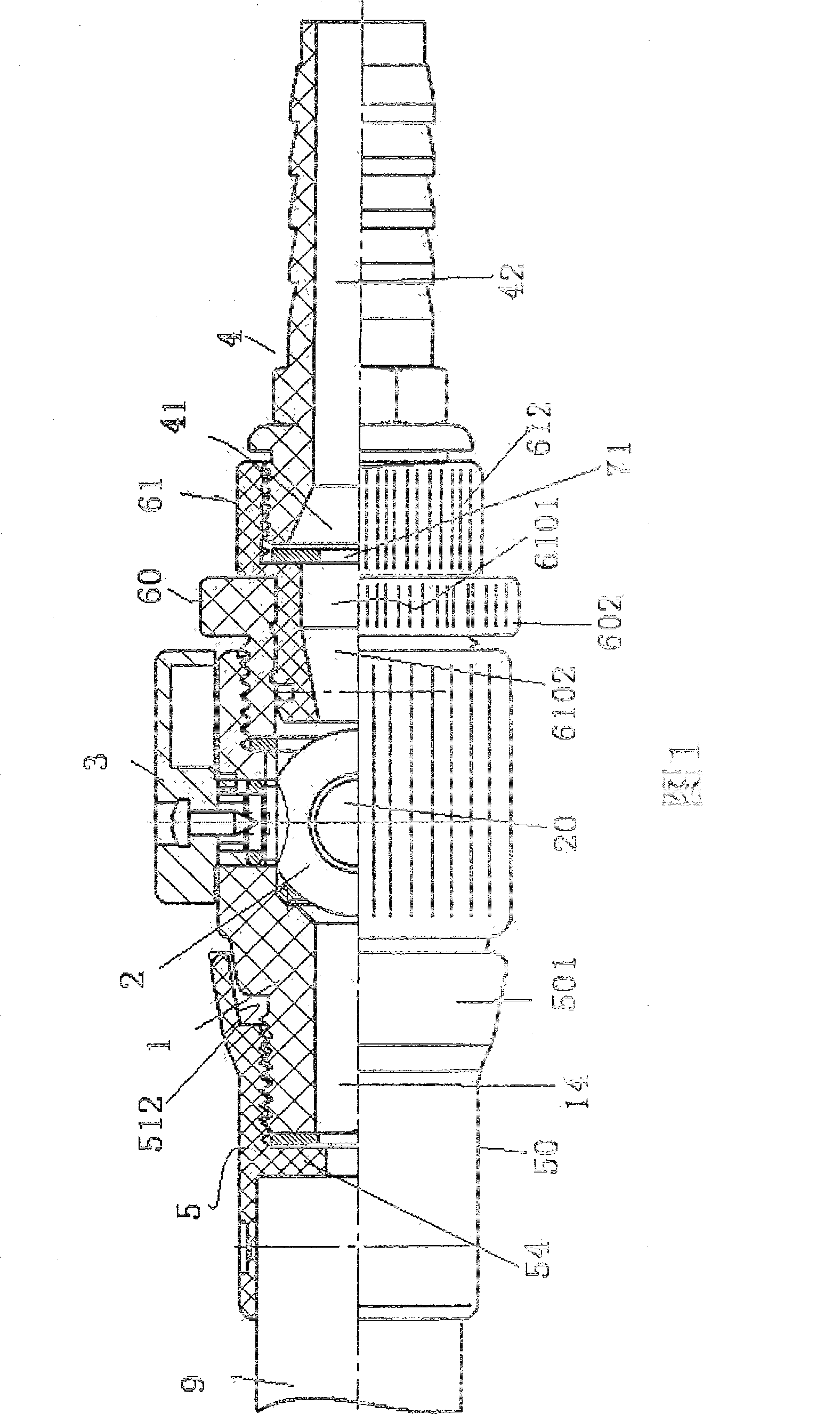

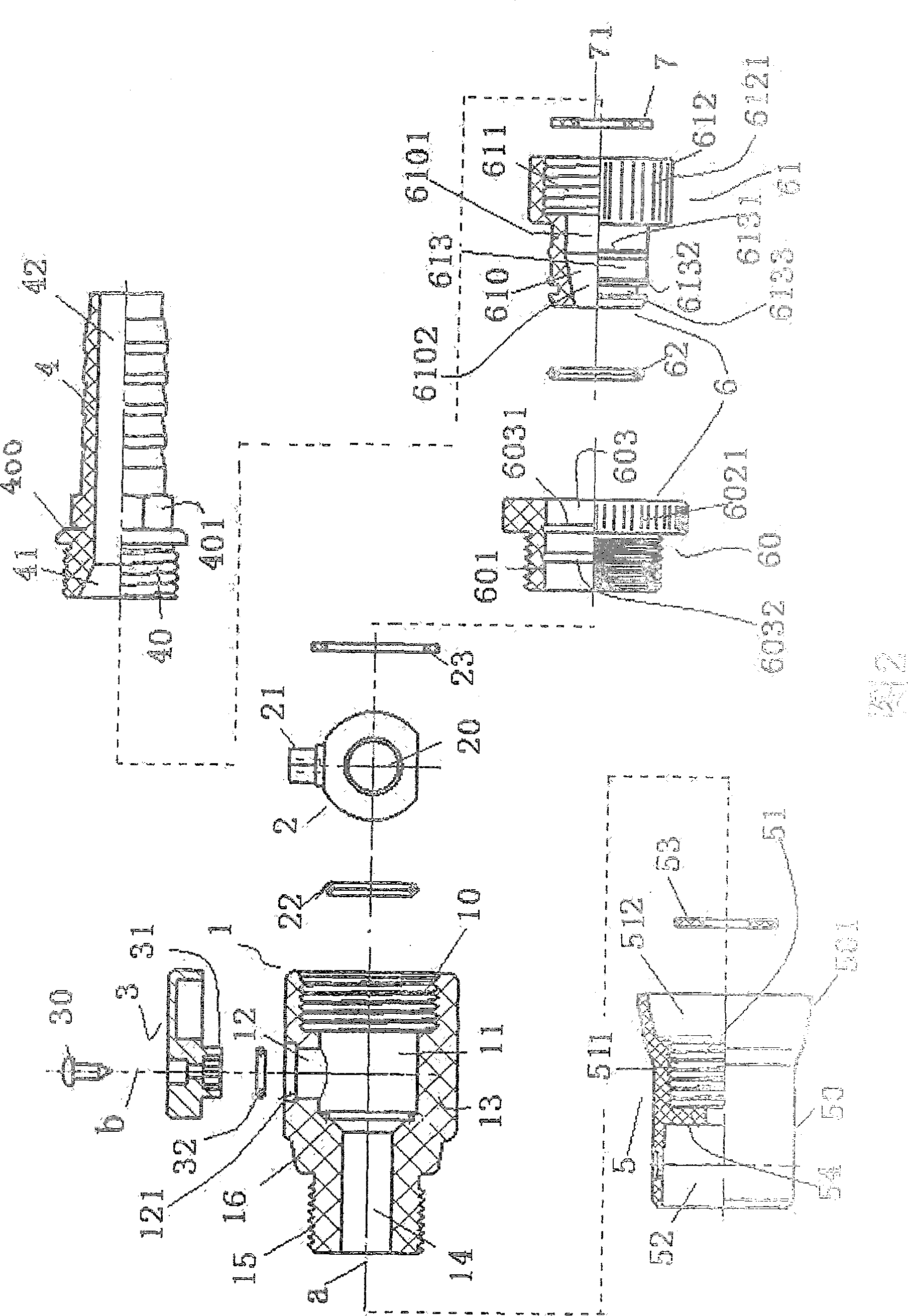

[0026] The specific embodiments, structures, features, and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0027] As shown in Figure 1-2, a water flow control device for a water spray tool includes a valve body 1 that can accommodate a spherical valve core 2. The spherical valve core 2 is turned by a rotary handle 3 to control the switching of water flow The main body 13 of the valve body 1 is cylindrical, one end of the main body extends outwards into a valve body water outlet coupling part 15 that is matched and combined with the rod body connector 5, and the other end of the main body has a valve body water inlet 10;

[0028] The main body 13 of the valve body is provided with a spherical valve core accommodating cavity 11 which extends upward to form a neck cavity 12 from which the handle 21 of the spherical valve core extends. The connecting end 31 of 3 is matched with the internal sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com