Two-impeller three-power washing machine and control method thereof

A control method and three-power technology, applied in the field of washing machines, can solve the problems of low washing degree of middle clothes, weak washing power of clothes, and weak water flow intensity, etc., to achieve enhanced rubbing and tumbling of clothes, improved washing uniformity, and enhanced water flow intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

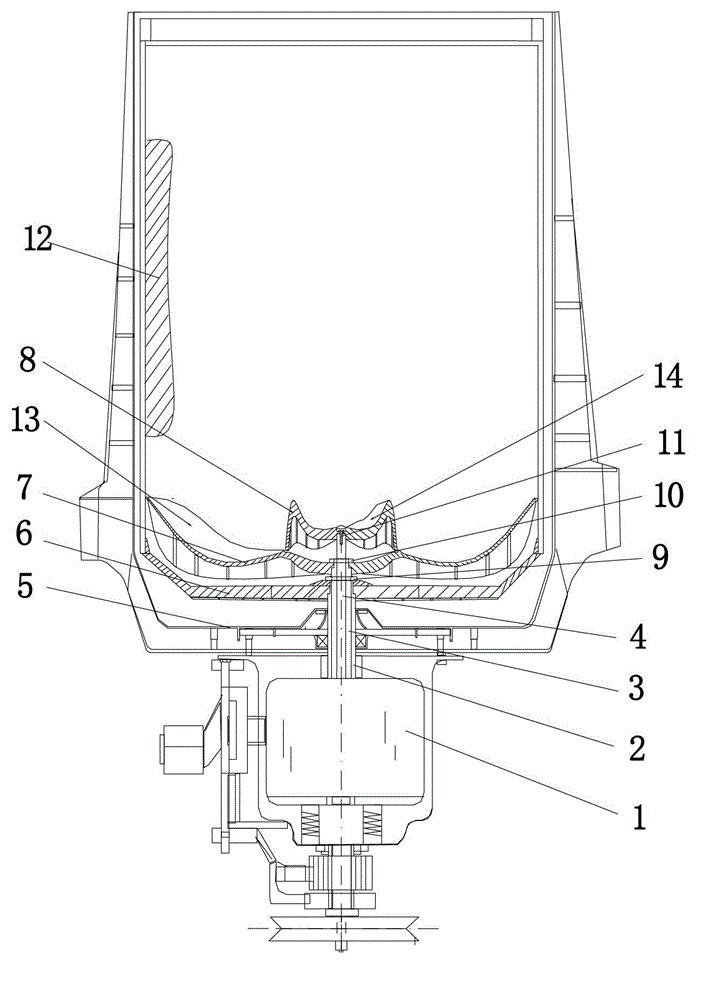

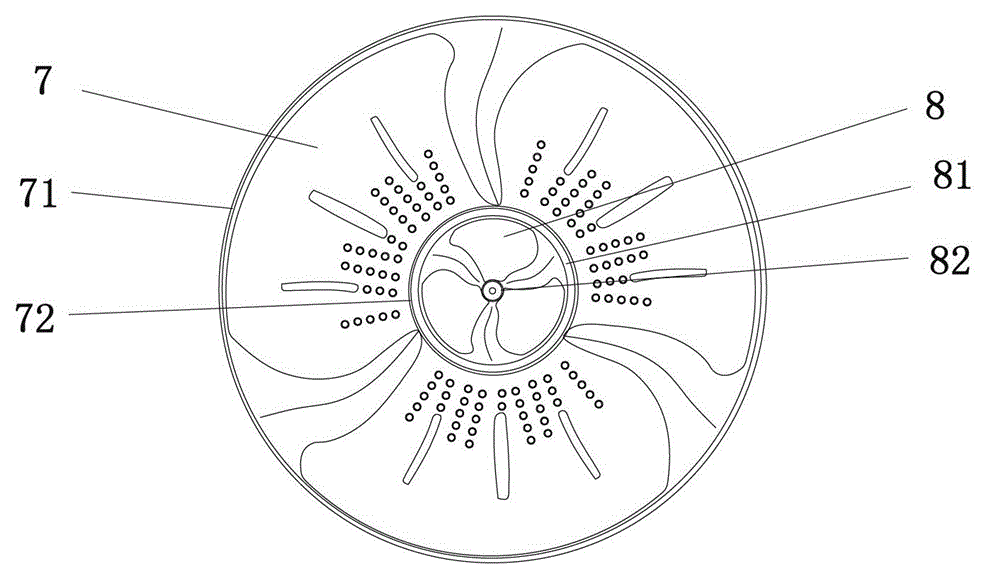

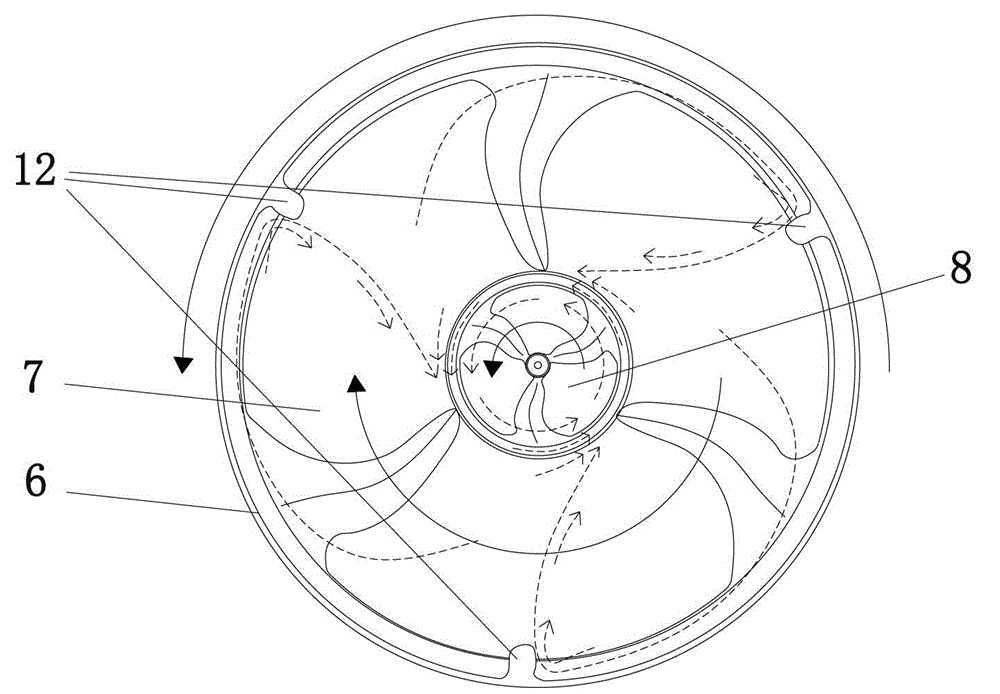

[0030] Such as figure 1 As shown, the double pulsator three-power washing machine provided by the present invention includes an outer tub 5, an inner tub 6, a main pulsator 7, an auxiliary pulsator 8 and a three-power reduction clutch 1, and the main pulsator 7 and the auxiliary pulsator 8 are located at At the bottom of the inner barrel 6, the auxiliary pulsator 8 is located above the central position of the main pulsator 7, and the inner barrel 6-main pulsator 7-auxiliary pulsator 8 are concentrically installed on the power rotating shaft of the three-power reduction clutch 1. The inner barrel 6 is set on the inner barrel shaft 2 of the three-power deceleration clutch 1 through the inner flange, and is fastened with the inner barrel fastening nut 9; the main wave wheel 7 is set on the inner barrel of the three-power deceleration clutch 1 through the inner flange Main pulsator rotating shaft 3 is fastened with main pulsator fastening nut 10; said auxiliary pulsator 8 is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com