A flexible concave screen with rotatable threshing unit

A concave plate sieve, flexible technology, applied in threshing equipment, agricultural machinery and tools, agriculture, etc., can solve problems such as millet damage and poor separation effect, achieve enhanced kneading and rolling effects, reduce broken rate, reduce impact force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

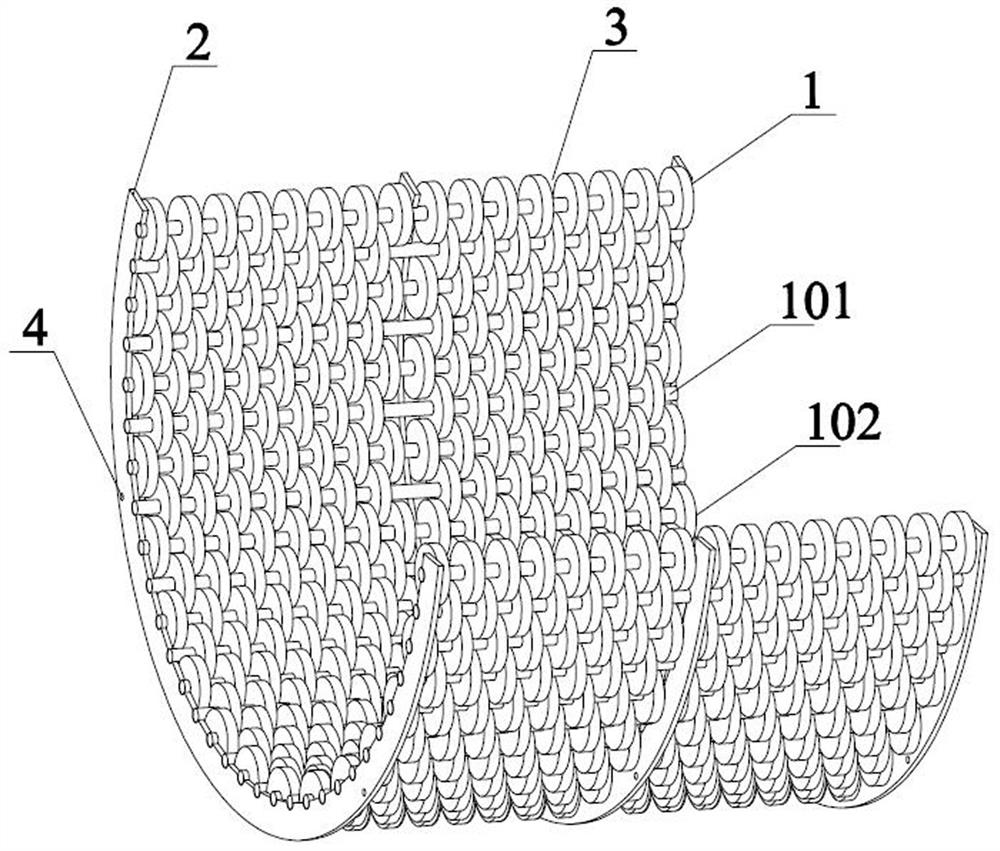

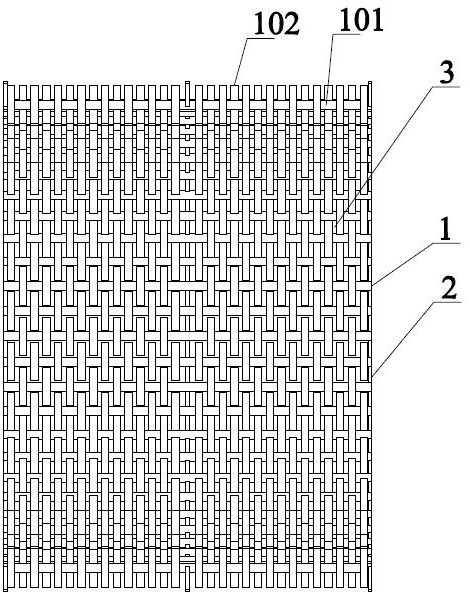

[0024] like figure 2 In, in this embodiment, the distance between the connection axes 101 in any two groups of adjacent flexible decarning unit group 1 is the same as the difference between the outer diameter of the decarning unit 102 and the inner diameter. The distance between the adjacent molty units on the same continuous connection 101, between the decarrency unit in any one -granular unit and the previous set of flexible decarning unit group 1 and the next set of flexible decarning unit group 1 Both formation of desktop holes 3 for the separation of valves.

Embodiment 2

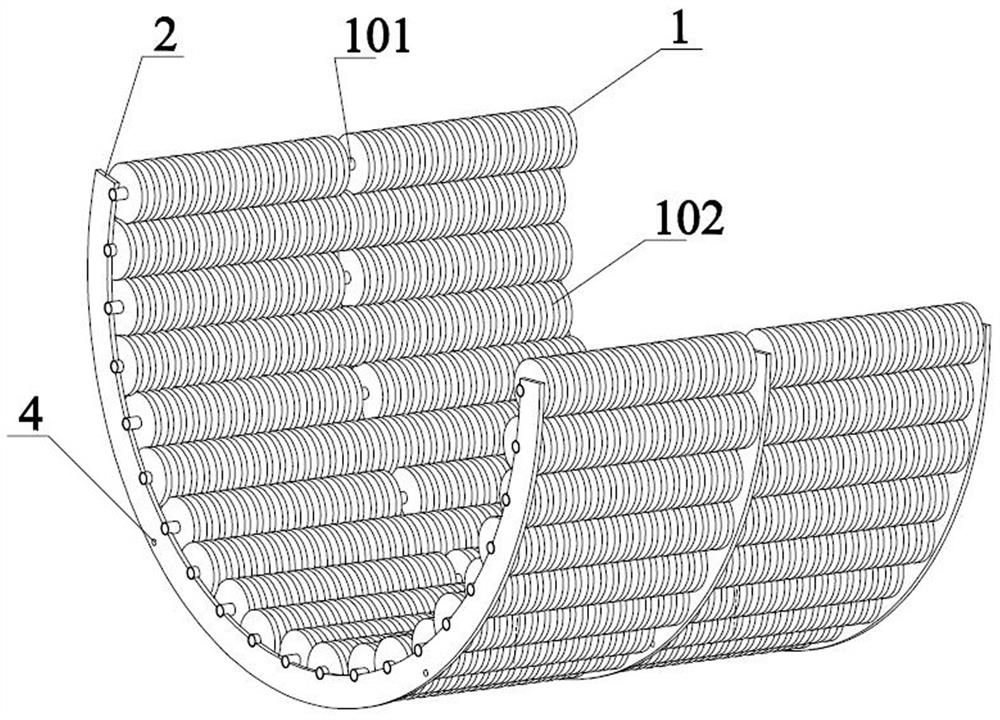

[0026] like Figure 4 In, in this embodiment, the height of the decarning unit is equal to the distance between the adjacent decarrency units located on the same connection 101, and any two groups of adjacent flexible decarning unit group 1 The connection axis 101 in the connection axis 101 The distance between the distance between the outer and the inner diameter of the decarning unit is greater; between the two decarrency units on the same connected axis 101, between the decarring unit and the previous set of flexible decarrencies group 1, and Between the desktop units in the next set of flexible decarning unit group 1, the desktop pores 3 for the separation of the valley are formed.

[0027] When the present invention is matched with the decarcular roller, at the moment when the two are in contact, because the material of the decarrencling unit is hollow -resistant rubber, the rigidity impact is a flexible impact, which can greatly reduce the impact when contacting; at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com