Automatic sand flushing device for upper electric field water discs

An automatic flushing and water tray technology, applied in the direction of electric/magnetic dehydration/demulsification, electric/magnetic refining, etc., can solve the problems of occupying space, affecting the normal operation of the upper electric field, etc., to reduce deposition and excellent self-lubricating performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

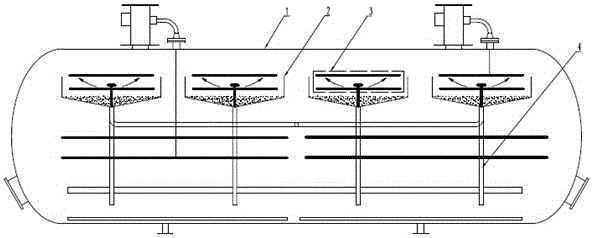

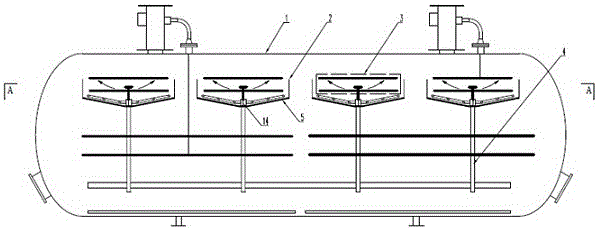

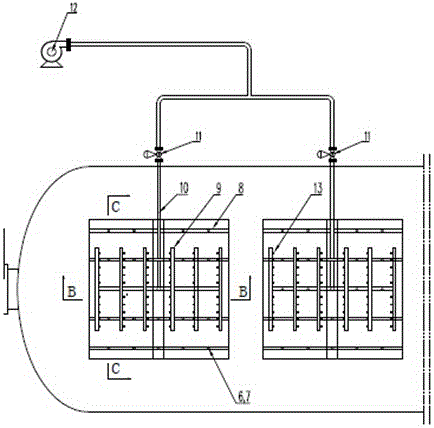

[0019] Such as figure 2 As shown, on the bottom surface of each water tray 2, one deck of automatic desanding plate 5 is compounded. The material of automatic desanding plate 5 is polytetrafluoroethylene sheet, or is sprayed polytetrafluoroethylene. The thickness of the PTFE sheet or sprayed PTFE coating is determined according to the degree of wear on the surface of the automatic sand removal plate by the deposited sediment and mechanical impurities, and the design service life. After the surface of the PTFE sheet is treated, it can be pasted on the bottom surface of the electric desalination tank. Also can weld several screws 6 at the bottom of every water tray 2, with nut 7 and pressing plate 8, the polytetrafluoroethylene sheet is pressed on the bottom of every water tray 2 (referring to figure 2 , Figure 5 ). Above the bottom of every water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com