Improved structure for gas and water mix backwash of aerating biological filter

A technology of aerated biological filter and improved structure, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of less consumables, improved backwashing effect, and simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

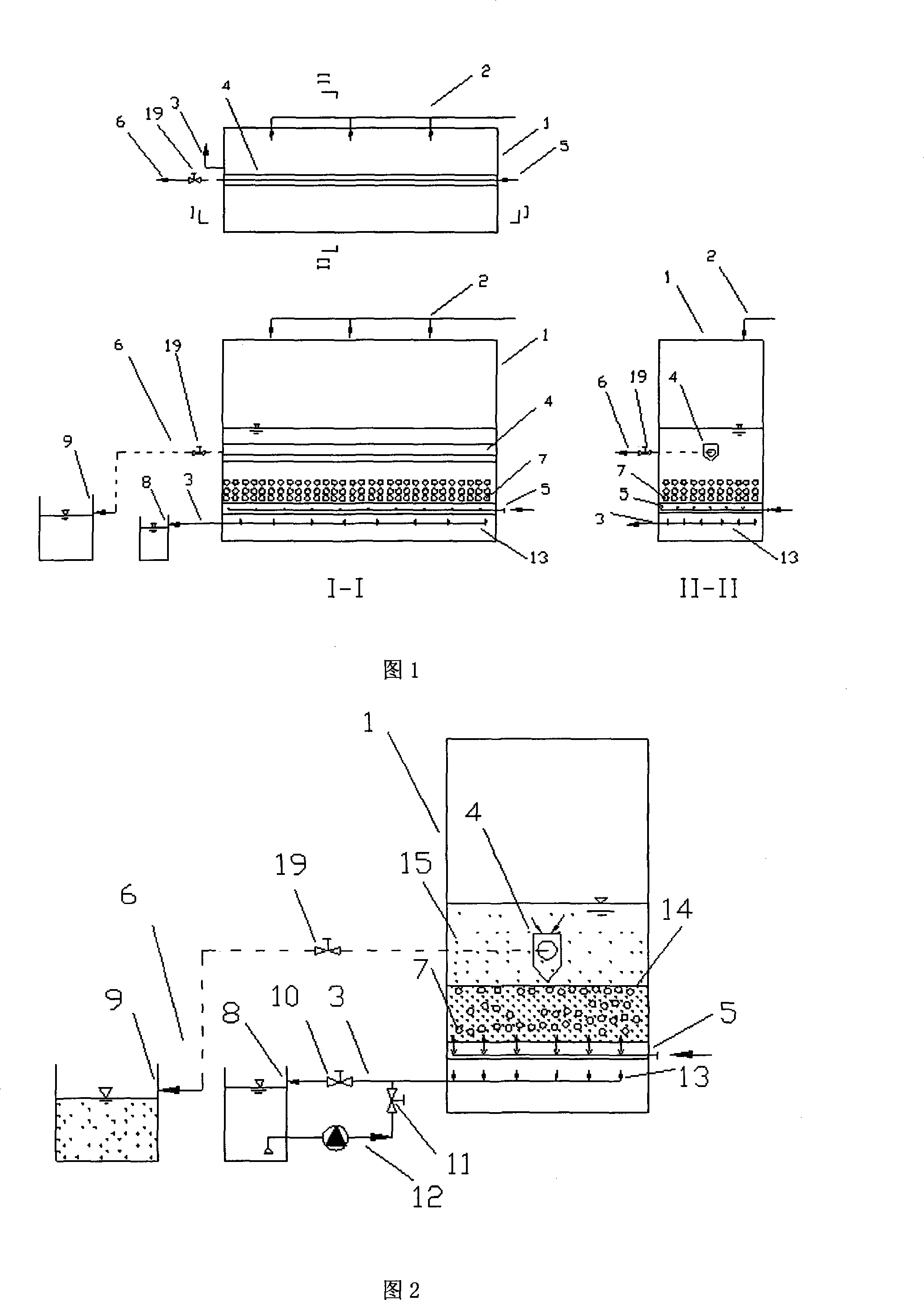

[0031] An improved structure for the mixed backwashing of air and water in a biological aerated filter. As shown in Figure 1, the sewage flows into the pool body 1 from the water inlet pipe 2, and the water body flows through the filter material 7 from top to bottom. Under the action of gravity, The water body flows to the clear water pool 8 through the water collection pipe network 13 and the water outlet pipe 3. When the sewage passes through the filter material 7, the air supply pipeline 5 inputs gas into the pool to provide the oxygen required for microbial growth. After the interception of the filter material and microbial degradation, Sewage is purified.

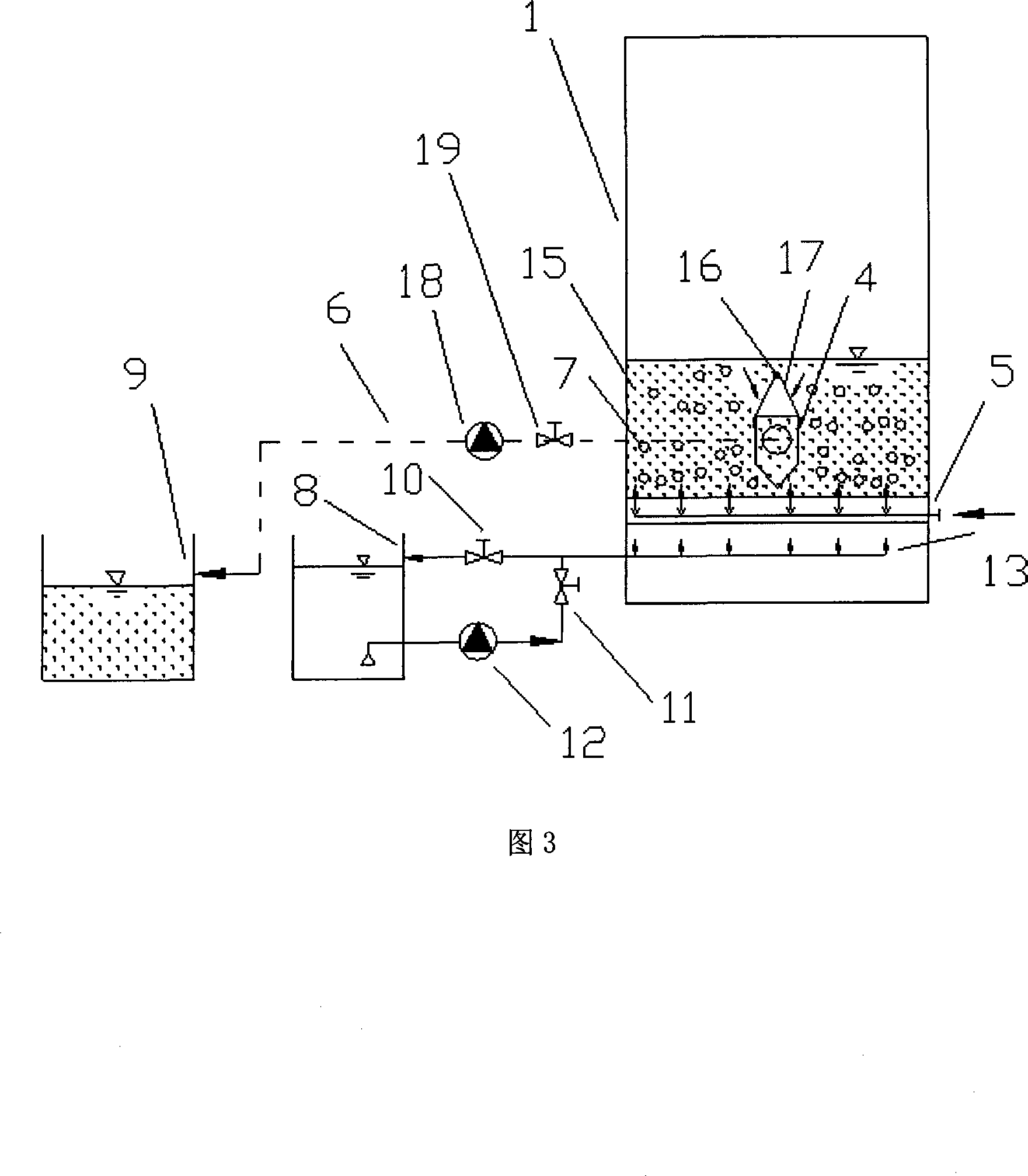

[0032] As shown in Figure 3, close the control valve 10, open the control valve 19 and the control valve 11, open the pressurized water pump 12 and the suction water pump 18, and increase the air flow of the air supply pipeline 5. The pressurized water pump 12 pumps the water in the clear water pool 8 into the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com