Laminated filter unit

A technology of lamination filtration and lamination group, which is applied in the direction of filtration separation, filtration circuit, fixed filter element filter, etc. It can solve the problems of poor cleaning effect, ineffective cleaning of impurities, and difficulty in installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

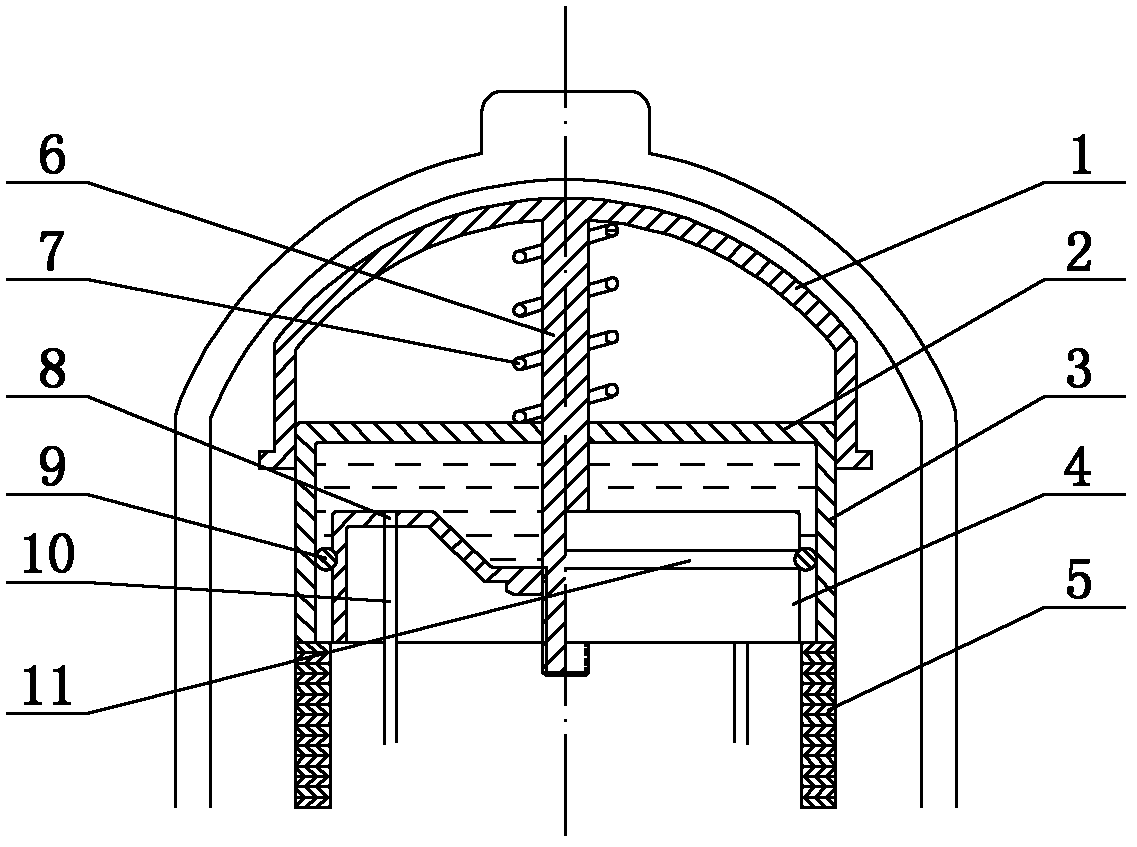

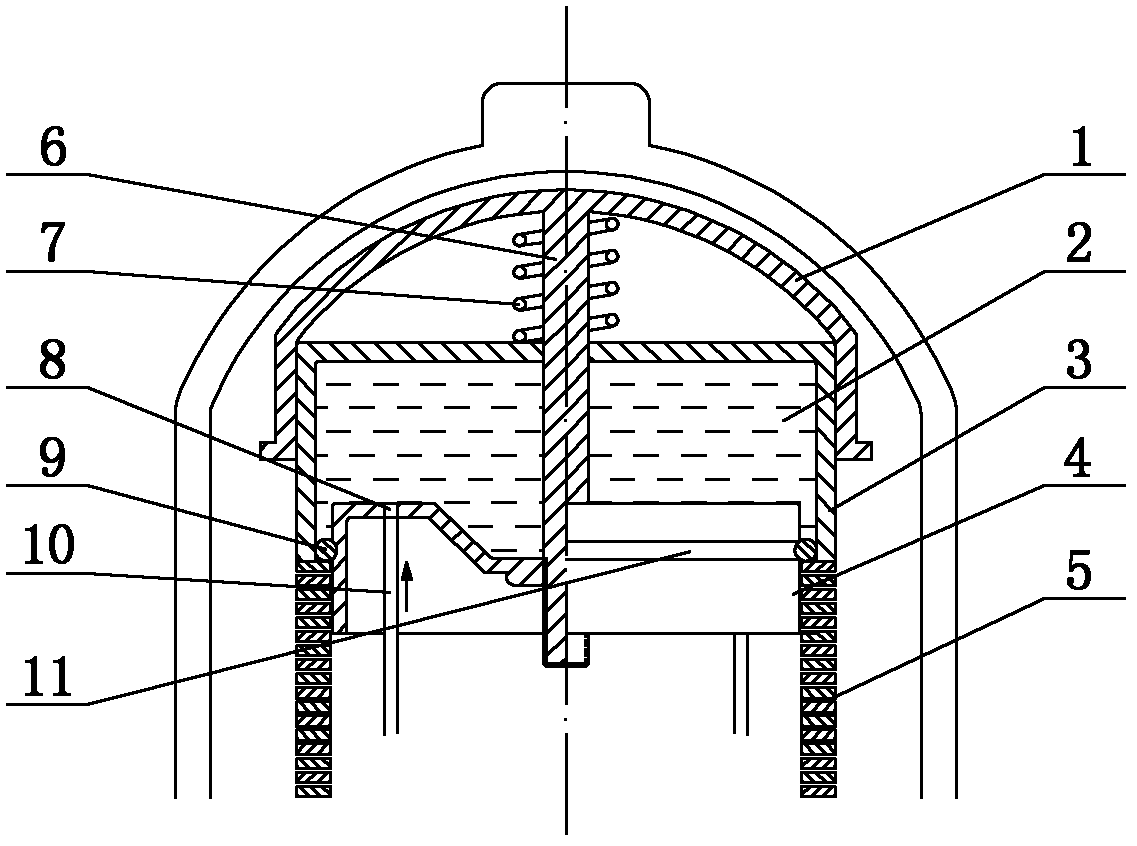

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

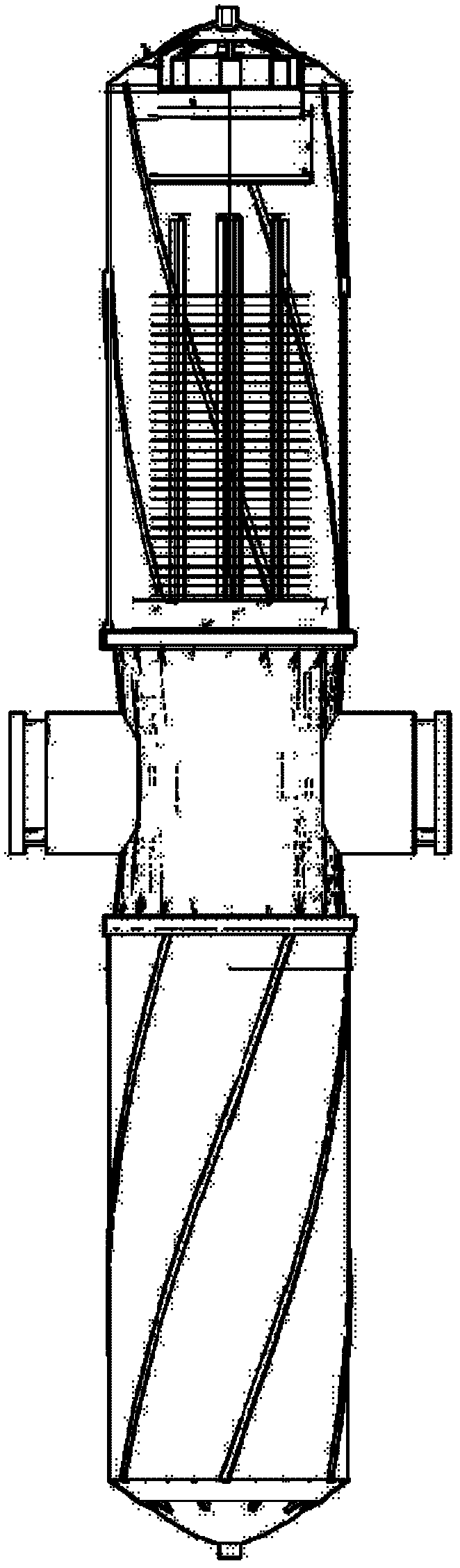

[0021] Such as Figure 1-Figure 6 Shown:

[0022] filter:

[0023] The liquid containing impurities enters the interior of the laminated filter unit from the inlet and enters the centrifugal guide vanes 12. When the liquid passes through the centrifugal guide vanes 12, high-speed rotation occurs, and the centrifugal force generated by the high-speed rotating liquid keeps the impurities in the liquid away from the laminated stack 5 And move up, and finally concentrate on the top of the laminated filter unit, which greatly reduces the backwashing frequency of the product. Under the action of the system pressure, the liquid is filtered through the gap of the laminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com