Filter

A technology of filters and filter chambers, applied in the field of filters, can solve problems such as liquid path failures, reduced quantitative sampling accuracy, and blockage of liquid path components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

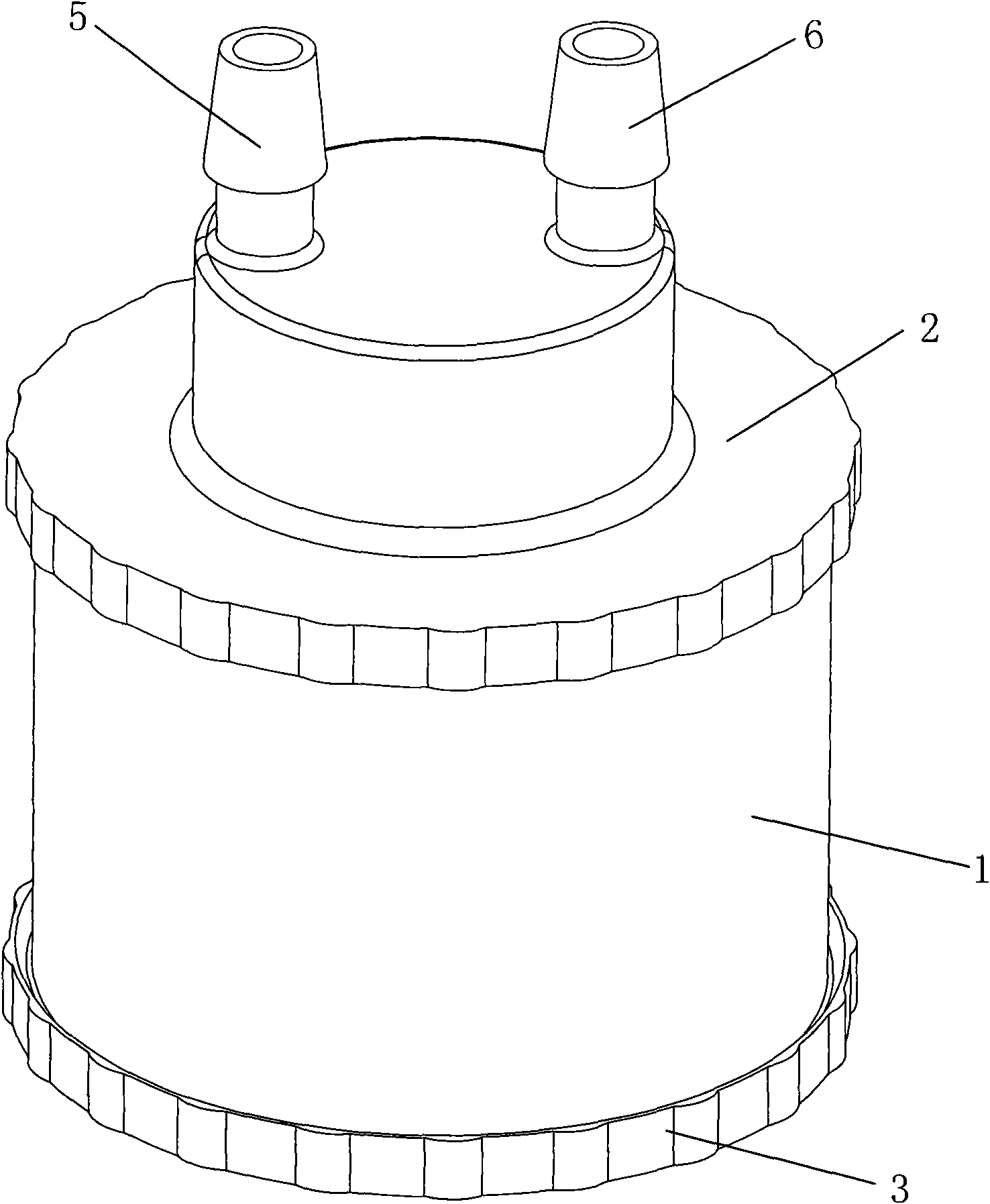

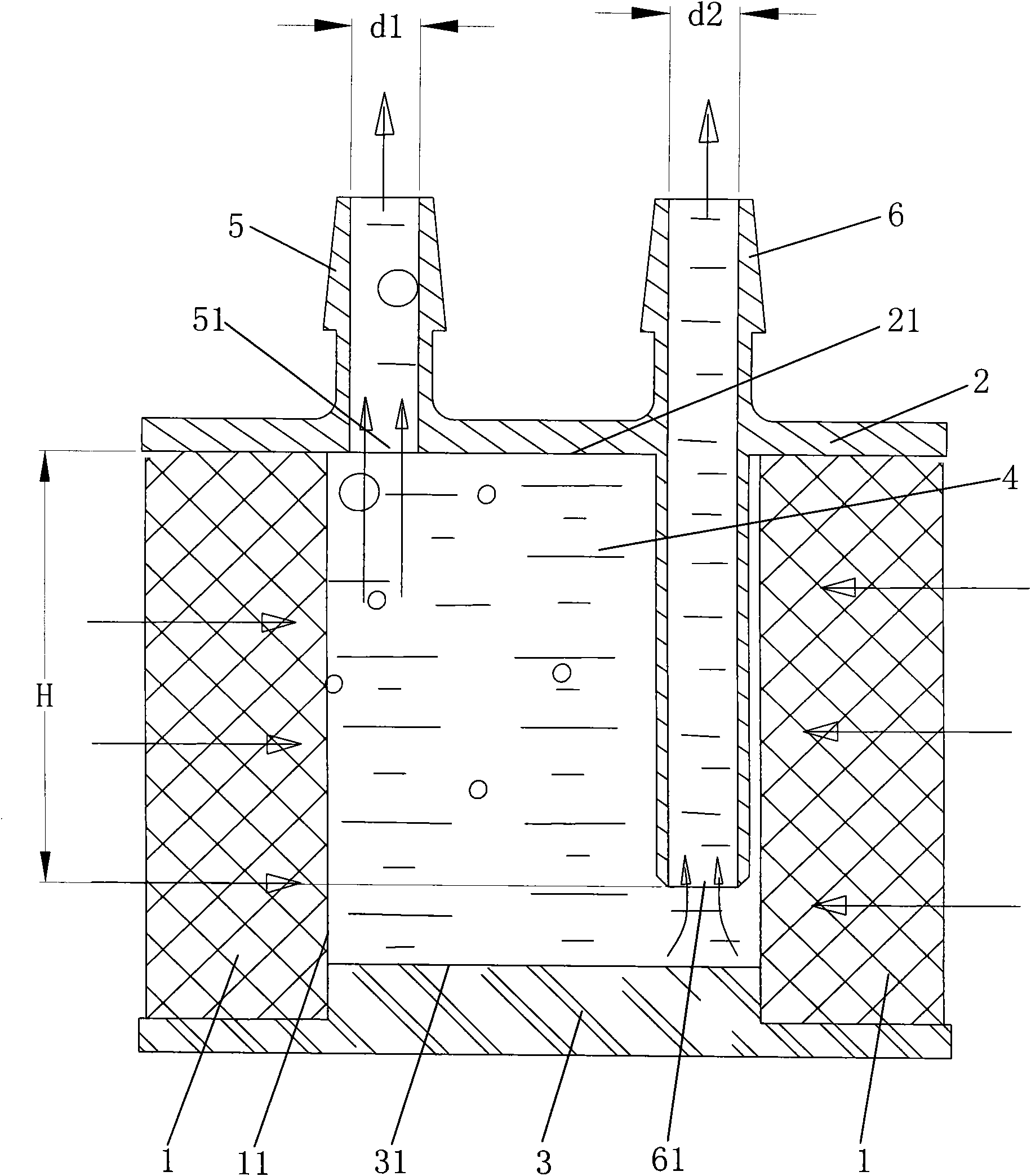

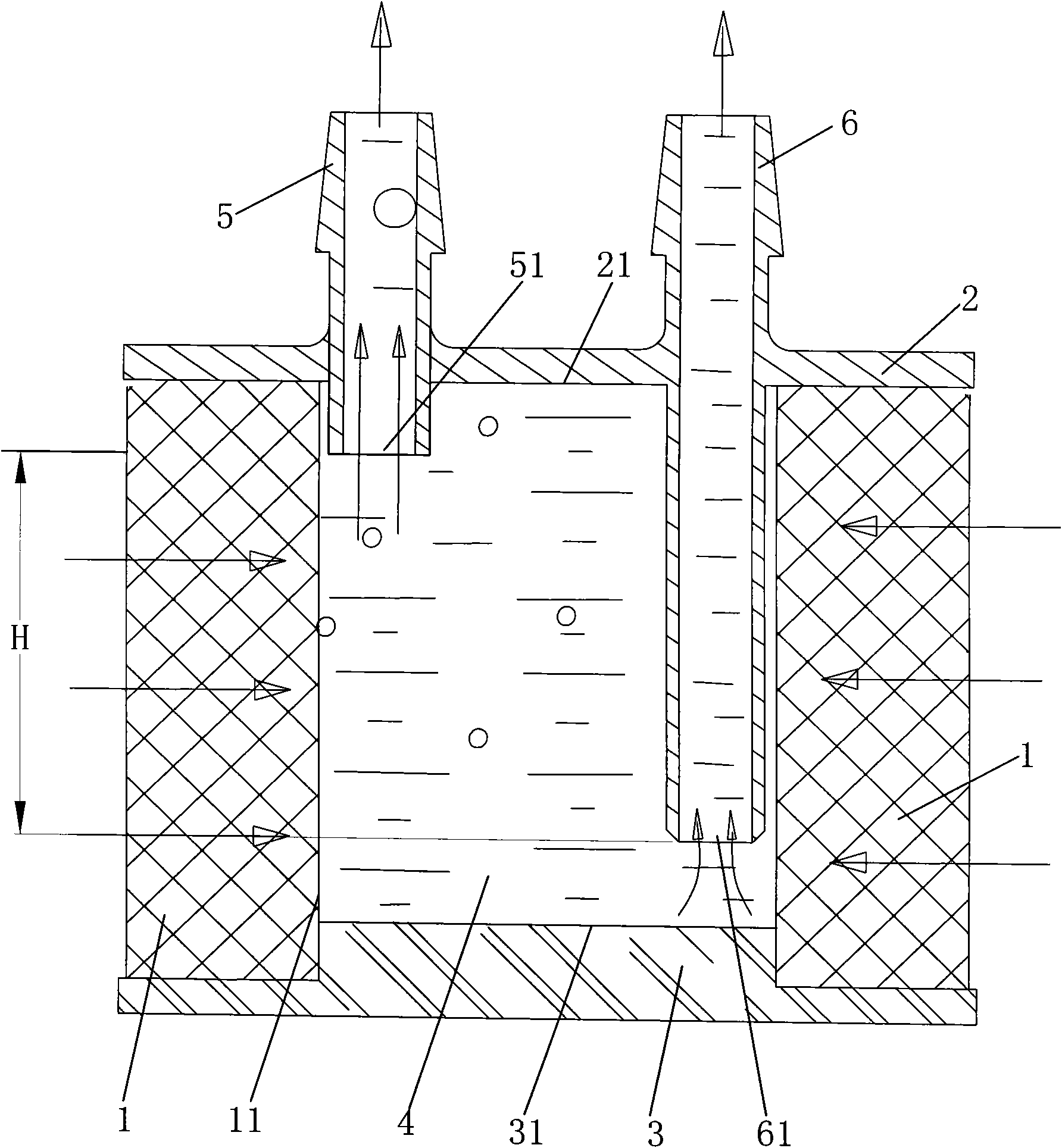

[0018] Such as figure 1 and figure 2 As shown, the filter in this embodiment includes a filter element 1 , a top cover 2 and a bottom cover 3 . The filter element 1 is a cylindrical structure penetrating up and down, the top cover 2 and the bottom cover 3 are respectively fixed on the top and bottom of the filter element 1, and the inner wall surface 11 of the filter element 1, the inner wall surface 21 of the top cover 2 and the bottom cover 3 The inner wall surface 31 of the filter cavity 4 is surrounded. The filter element 1 is provided with a plurality of slits for introducing the fluid to be filtered into the filter cavity, and the fluid is a mixture of gas and liquid. The top cover 2 is provided with a first discharge pipe 5 and a second discharge pipe 6, the first discharge pipe 5 is vertically fixed on the top cover 2, the first discharge pipe 5 communicates with the filter chamber 4, and the first discharge pipe 5 is connected to the filter chamber 4. The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com