An industrial coolant purification device

A technology of purification device and cooling liquid, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of high use cost of chemical fiber products, secondary pollution of natural environment, waste of petrochemical resources, etc., and achieve simple replacement operation. Convenience, improve enterprise efficiency, smooth filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

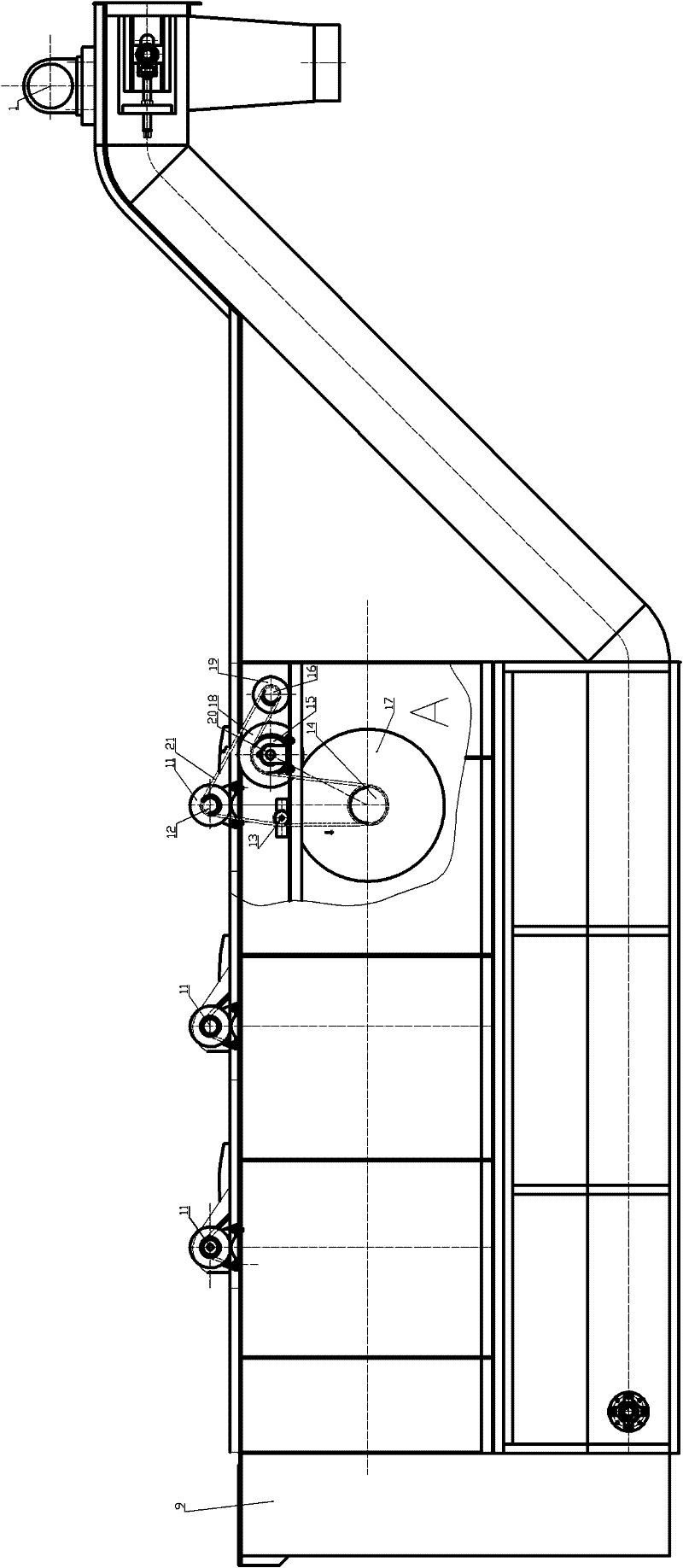

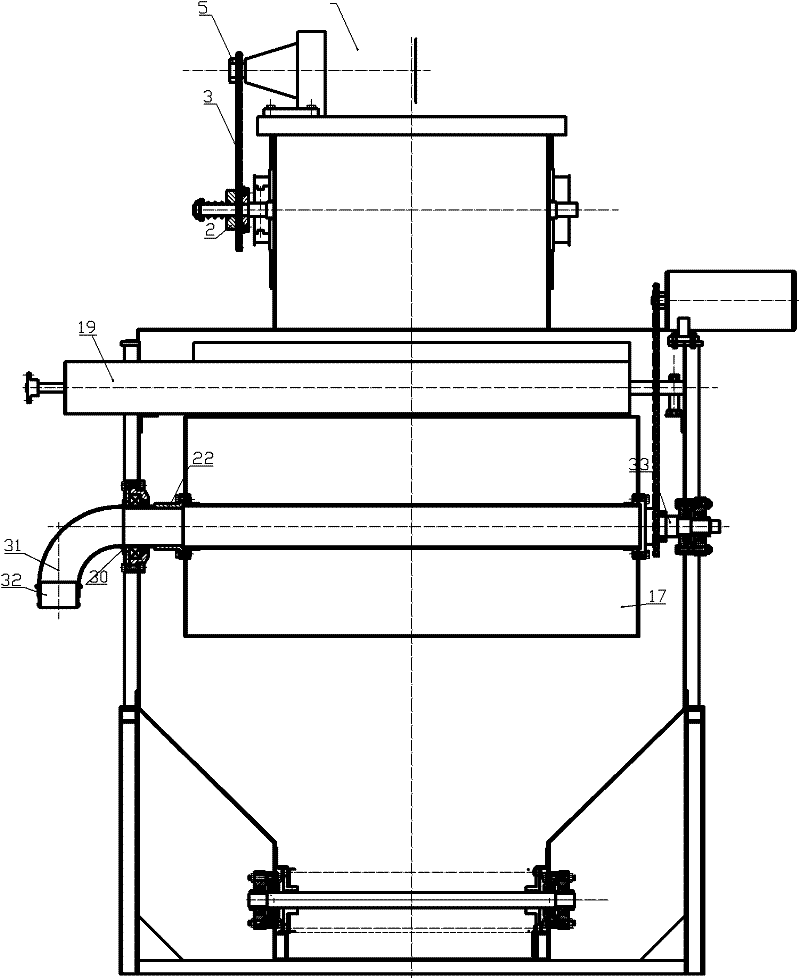

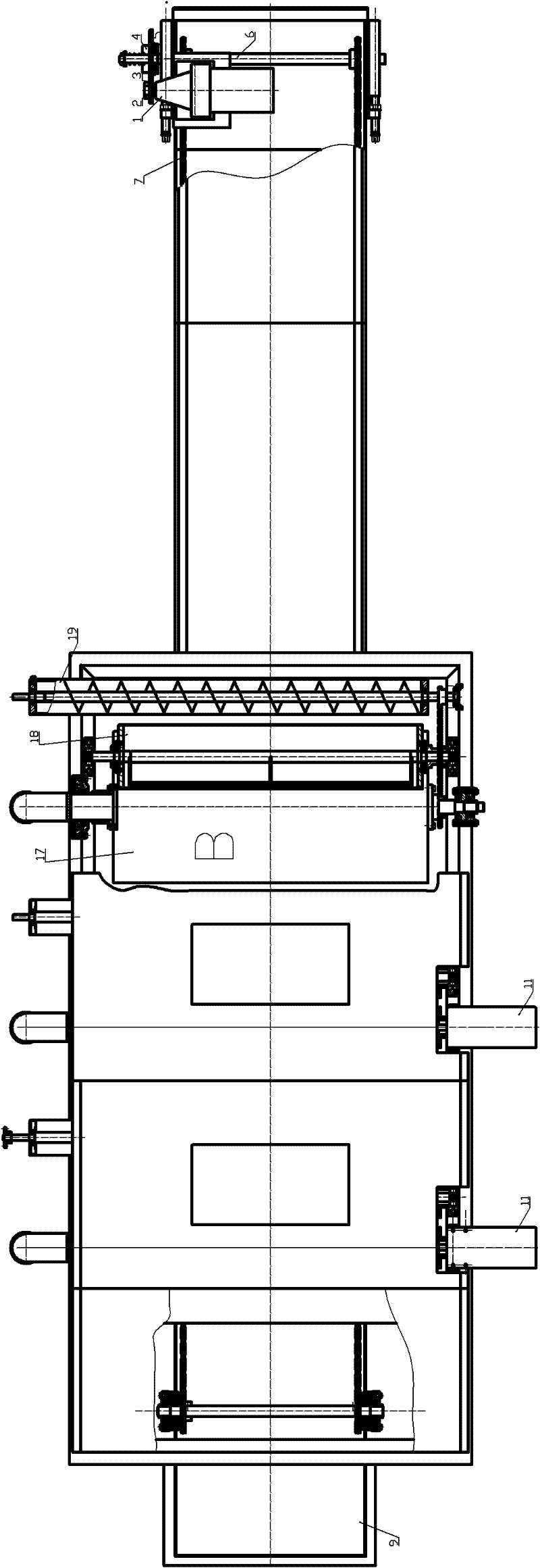

[0036] The present invention will be further described below in conjunction with accompanying drawing, as Figure 1-5 As shown, an industrial coolant purification device includes a buffer water inlet tank, multiple sets of filter devices and a scraper chain slag discharge device; the multiple sets of filter devices are installed side by side on the upper part of the buffer water inlet tank, and the scraper The plate chain slag discharge device includes a horizontal section and an ascending section, the horizontal section is located at the lower part of the buffer inlet tank, and the ascending section is located outside the right side of the buffer inlet tank;

[0037] The filter device includes a rolling cage filter device, a magnetic roller adsorption device and a twisted cage slag discharge device;

[0038] The rolling cage filter device includes a cage type filter cartridge 17, a fine stainless steel filter screen, a transmission spindle 33, a transmission reducer 11, a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com