Porous packing coated membrane bioreactor (MBR) device and sewage treatment method

A porous filler and coated technology, which is applied in the field of porous filler coated MBR devices, can solve the problems of easy pollution of MBR biofilm reactors and high cost of replacing membrane components, so as to alleviate the problem of membrane fouling, save infrastructure costs, reduce Effect of backwash frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

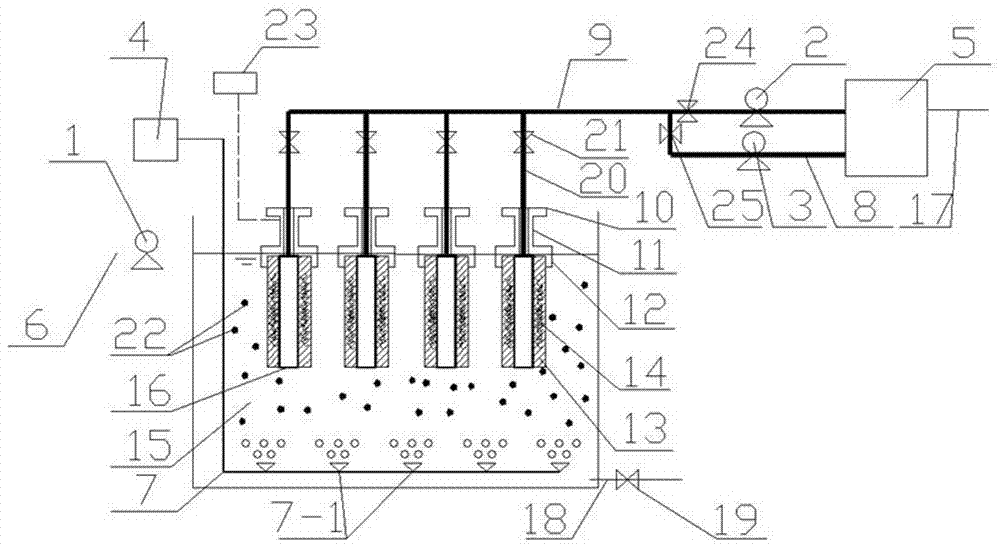

[0031] This embodiment discloses a method for sewage treatment using the porous filler-coated MBR device described in Example 1, which includes the following steps:

[0032] 1. Operation stage:

[0033] The inlet water (slightly polluted water) enters the reaction tank 15 through the inlet pipe 6 under the suction action of the inlet pump 1. Under the normal working conditions of the air compressor 4, the aeration system 7 and the aeration head 7-1, the slightly polluted water The pollutants in the water are degraded and metabolized by the activated sludge 22 and the biofilm 14 on the porous polyurethane sponge filler 13, and the water quality is purified. The MLSS of the activated sludge in the reaction tank 15 is 200mg / L, the dissolved oxygen concentration is 5mg / L~6mg / L, and the hydraulic retention time is 12~24h. The purified slightly polluted water passes through the internal holes on the porous polyurethane sponge filler 13 , and is pumped through the ceramic membrane 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com