A high-salt wastewater treatment system and process for salt separation and concentration

A high-salt wastewater treatment system technology, which is applied in the high-salt wastewater salt separation and concentration treatment system and process field, can solve the problems of unstable operation of the system, difficult operation and control, and many sediments, so as to avoid the difficulty of dosing operation and control, Selective and high-throughput, high-selective and high-throughput effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

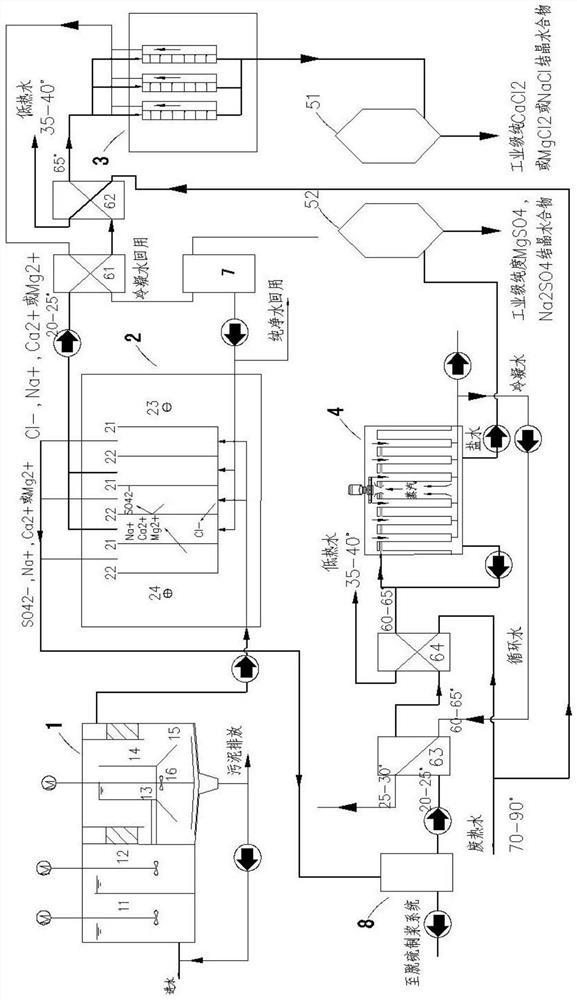

[0038] combine figure 1 As shown, Embodiment 1 discloses a high-salt wastewater salt separation and concentration treatment system, which mainly includes a pretreatment device 1, a selective ion electrodialysis device 2, a nanomembrane distillation device 3, a thin film MVR evaporation device 4, a crystallizer 51, a crystallizer Device 52, heat exchanger 61, heat exchanger 62, heat exchanger 63, heat exchanger 64, pure water tank 7 and sulfate temporary storage tank 8.

[0039] The pretreatment device 1 is a high-efficiency sedimentation device integrating reaction, flocculation and sedimentation, which is composed of an external circulation pump and an internal circulation stirring and lifting device, and is mainly used for coagulation reaction precipitation and chemical conditioning. The pretreatment device 1 can directly adopt the "circulation high-efficiency sedimentation device" disclosed in CN203866080U. The device is mainly composed of a stirring reaction zone 11, a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com