Automatic backwashing system in filtering device with multi filter drums

A filtration device and backwashing technology, applied in the direction of fixed filter element filter, filtration separation, membrane filter, etc., can solve the problems of manpower and material resources, low production efficiency, less filtered water, etc., and achieve extended life, perfect function, The effect of strong water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

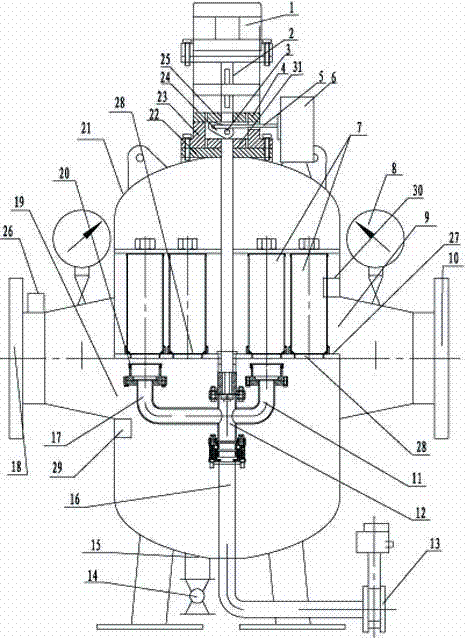

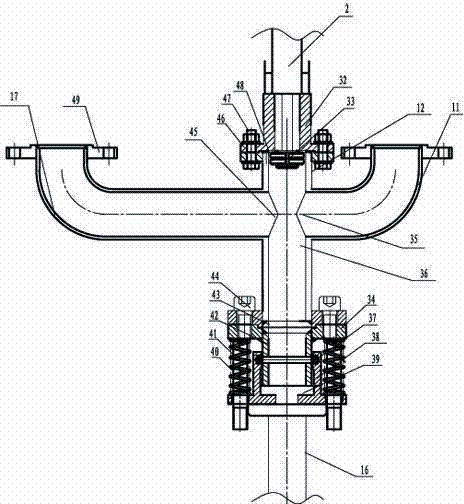

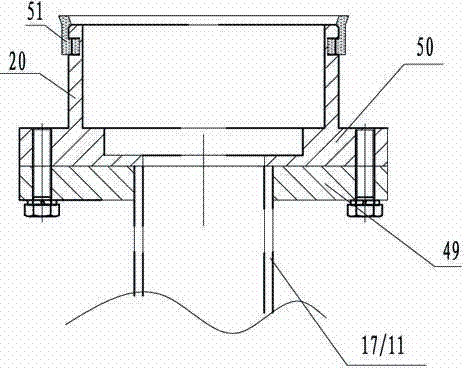

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, this embodiment includes a motor 1 with a reducer, a main shaft 2, a four-way connection seat 12, two elbow-type rotating arms 11, 17, a suction nozzle 20, a sewage pipe 16, a pneumatic sewage valve 13, a lifting mechanism, Two pressure sensors 29, 30 and backwash control system. The motor 1 with the reducer and the lifting mechanism are arranged above the housing 21 of the multi-cartridge filter device, and the four-way connection seat 12 and the two rotating arms 11, 17 are located in the lower chamber. The output gear of the reducer meshes with the gear on the upper end of the main shaft 2, the output gear of the reducer is thicker than the main shaft gear, and the thickness difference is not less than the height of the main shaft rising or falling. The motor 1 with the speed reducer is fixed on the filter device housing 21 . The upper end of the main shaft 2 is equipped with a lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com