Improved water chestnut harvester

An improved harvester technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., can solve problems such as horseshoe leakage, low work efficiency, and difficult to dig soil, so as to ensure integrity and work High efficiency and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

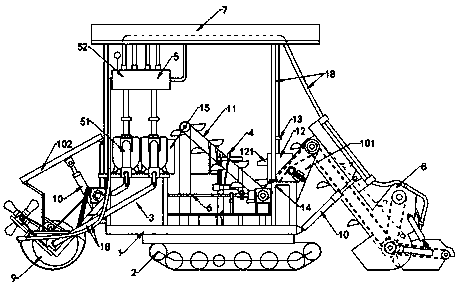

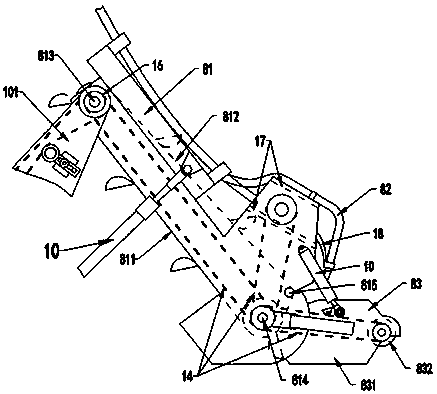

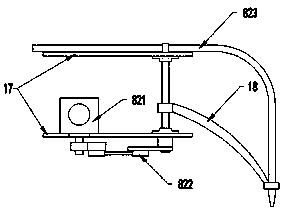

[0022] Depend on figure 1 Known, a kind of improved horseshoe harvester comprises crawler fuselage, and described crawler fuselage is made up of frame 1 and the crawler wheel 2 that frame 1 bottom is provided with; Described frame 1 is provided with engine room 3 , a control room 4, a reducer, a water supply device 5, a transmission device 6 and a shelter 7; the front end of the frame 1 is also movably connected with a collection mechanism 8, and the rear end of the frame 1 is also movably connected with a filtering water intake device 9, The collection mechanism 8 and the filtering water intake device 9 are respectively lifted by hydraulic cylinder 10. A conveying mechanism 11 is arranged in the middle of the frame 1. A water tank 12 is arranged between the conveying mechanism 11 and the collecting mechanism 8. A high-pressure water gun 13 is arranged on the water groove 12. The water tank 12 is provided with a discharge port 121 on the side facing the delivery mechanism 11; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com