Air-cooled electromagnetic heating device for plastic extrusion equipment

A technology of electromagnetic heating device and extrusion equipment, applied in the direction of induction heating device, induction heating, etc., can solve the problems of affecting production stability, product quality decline, short device life, etc., and achieve the goal of improving temperature control accuracy and power saving rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the technical solution of the invention will be further explained through the embodiments and the accompanying drawings.

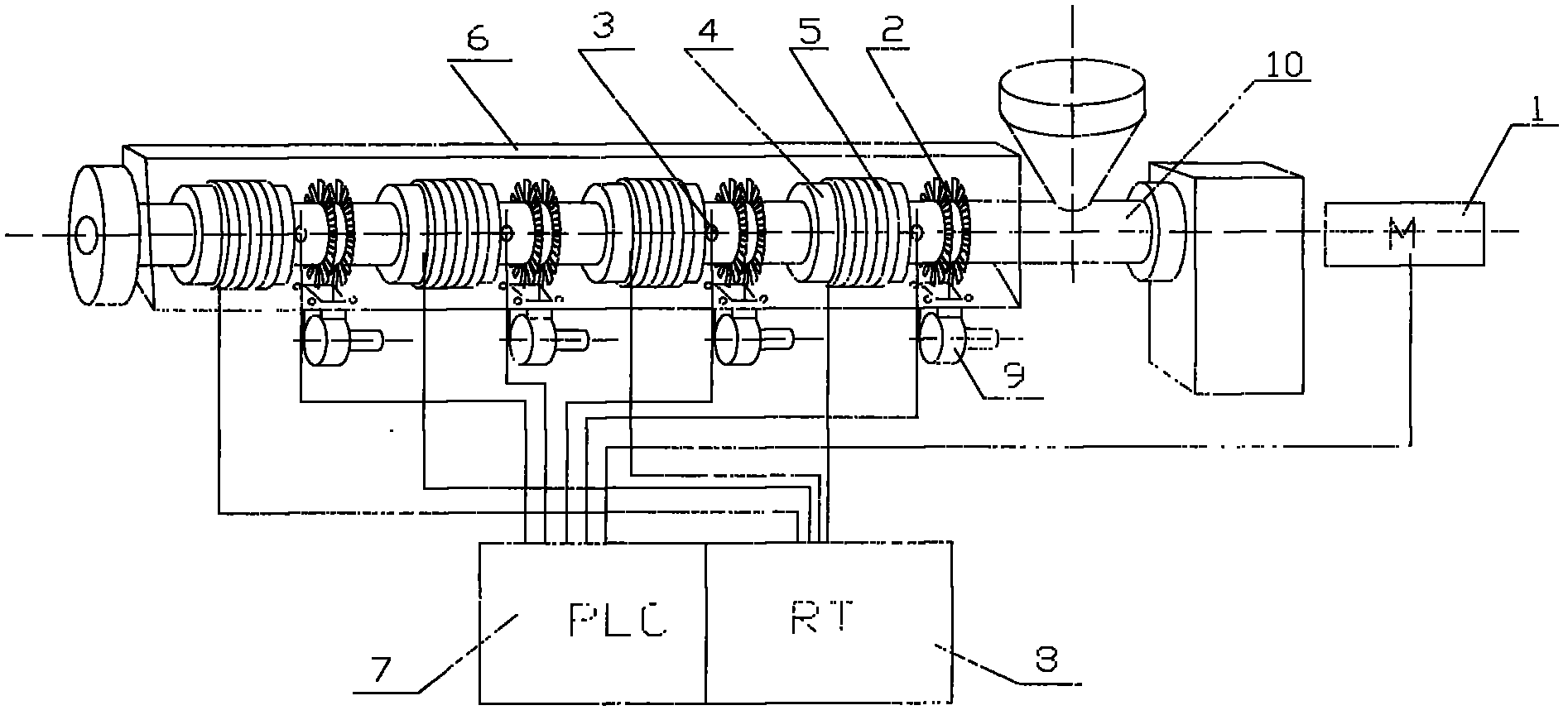

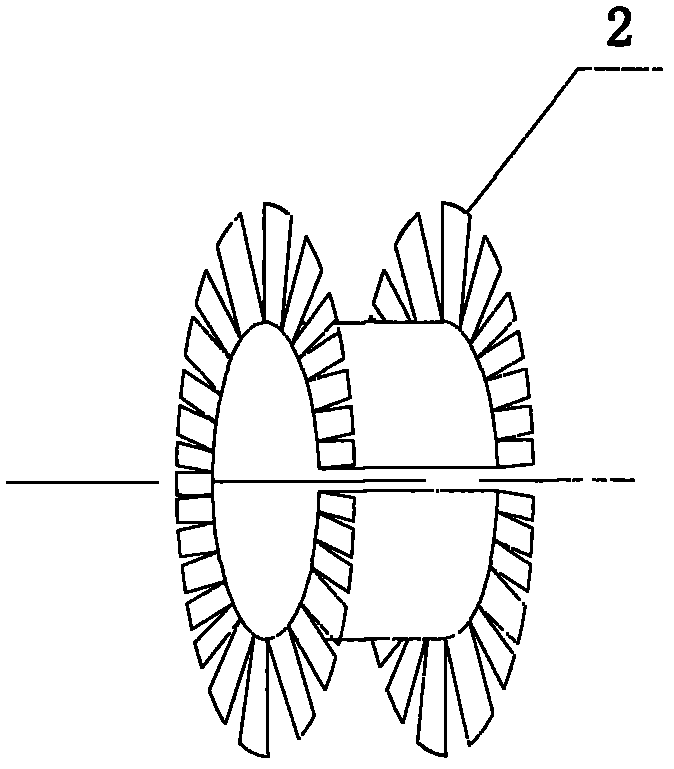

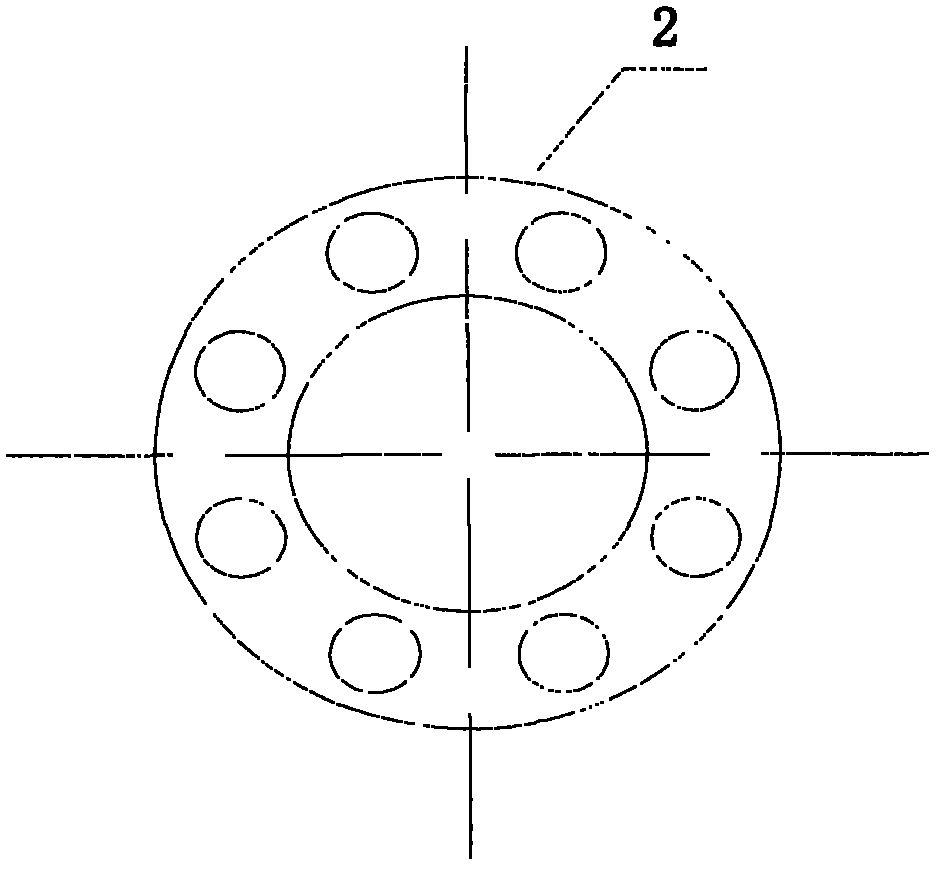

[0025] Such as figure 1 , 2 As shown, Embodiment 1 includes an insulation layer 4, an electromagnetic induction coil 5, and a temperature measuring element 3. The insulation layer 4 is wound around the barrel 10 in sections, the electromagnetic induction coil 5 is wound outside the insulation layer 4, and the temperature measuring element 3 is arranged at The bare barrel 10 also includes a cooling system and a controller for cooling the barrel 10. One end of the controller is connected with the screw motor 1 state detection element and the temperature measurement element 3, and the other end is connected with the electromagnetic induction coil 5 and the cooling system. The controller controls the operation of the cooling system and the electromagnetic induction coil 5 according to the state detection signal of the screw motor 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com