Electricity-saving control method and device of frequency converter

A technology of power-saving control and frequency converter, which is applied in the direction of electric controller, low-speed motor control, AC motor control, etc., can solve the problems of reducing motor life, power system interference, and not considering the working state of the motor, so as to reduce the interference of the power grid , solve the system lag, improve the effect of power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

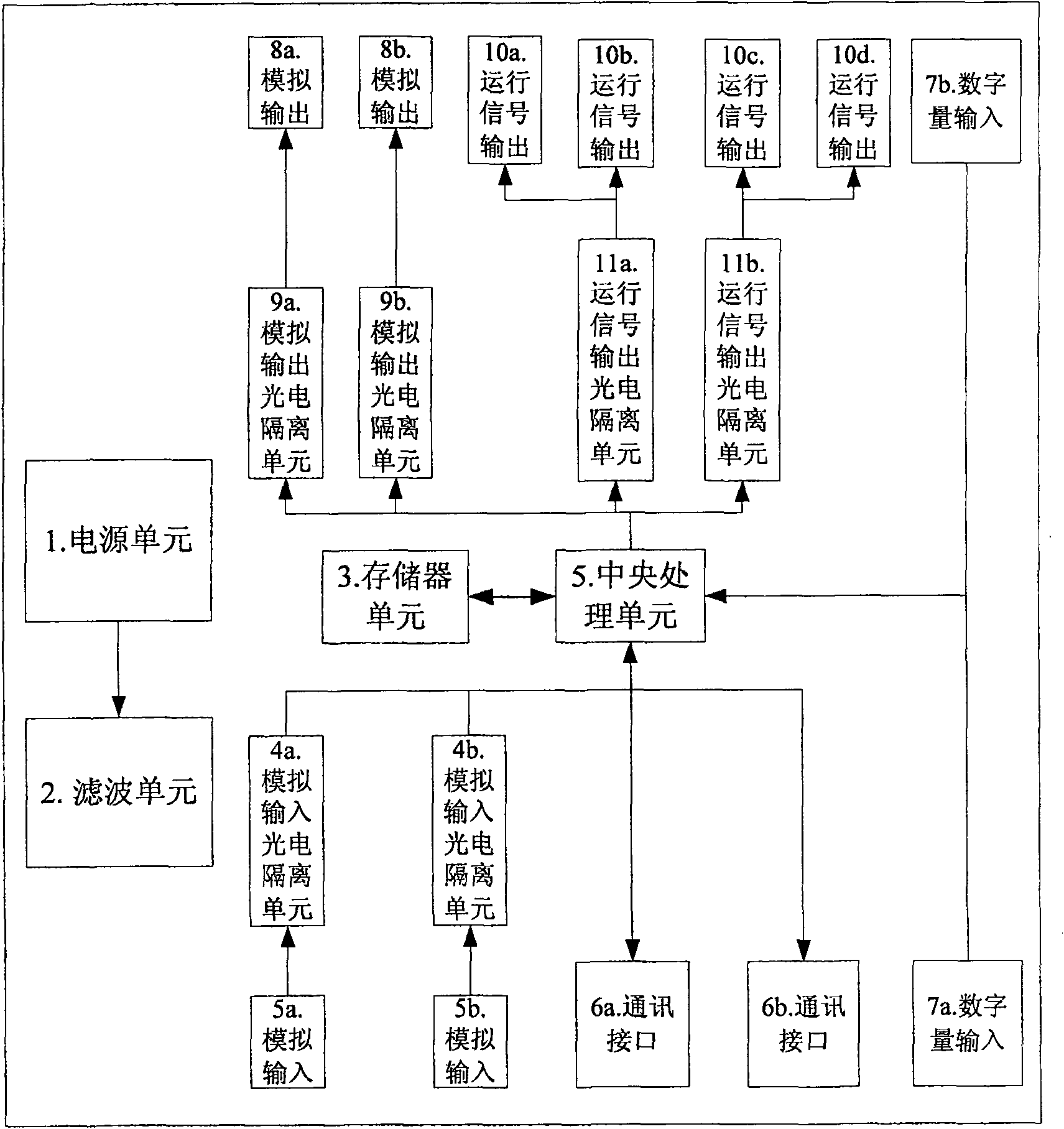

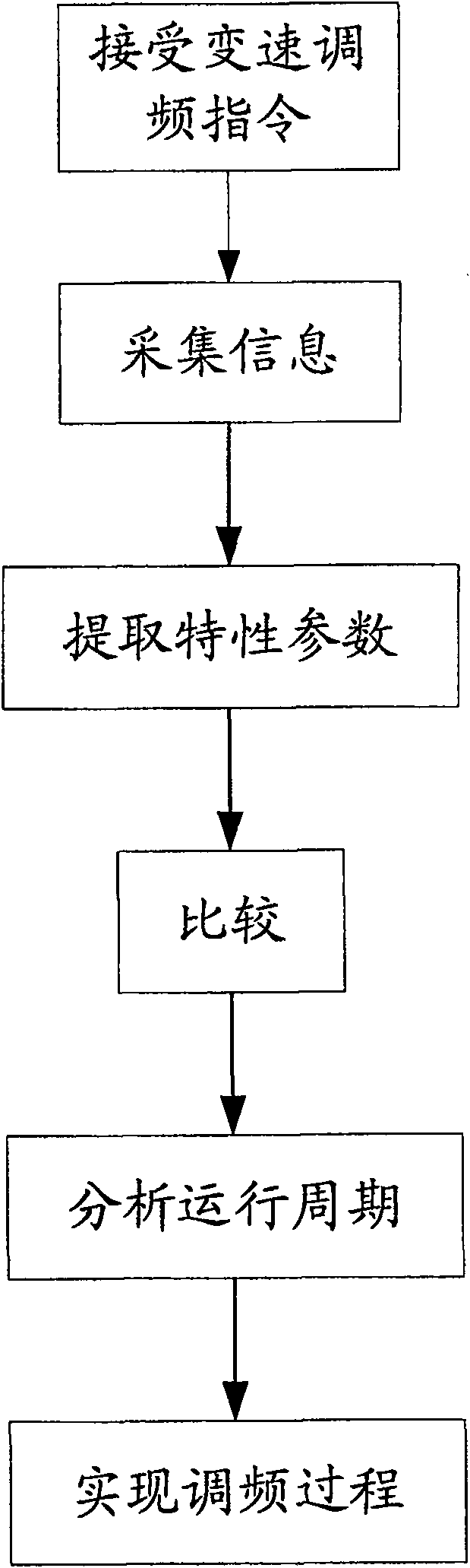

[0020] This embodiment is a power-saving control method for frequency converters. The hardware system used is such as figure 1 As shown, including: inverter power-saving control device with CPU and storage elements. For the procedure of the method, see figure 2 As shown, the steps include:

[0021] The step of accepting the instruction of variable speed and frequency modulation, this instruction can be sent by a person or by a certain sensor of the automation system. For example, in the refrigeration and air-conditioning system, it can be a temperature set manually, and this temperature is different from the existing room temperature, so it is necessary to change the temperature, increase or decrease the speed of the motor, so as to realize the change of cooling capacity. It may also be that when the temperature sensor in the room reaches a certain set temperature threshold, the rotation speed of the motor needs to be increased or decreased to maintain the temperature in th...

Embodiment 2

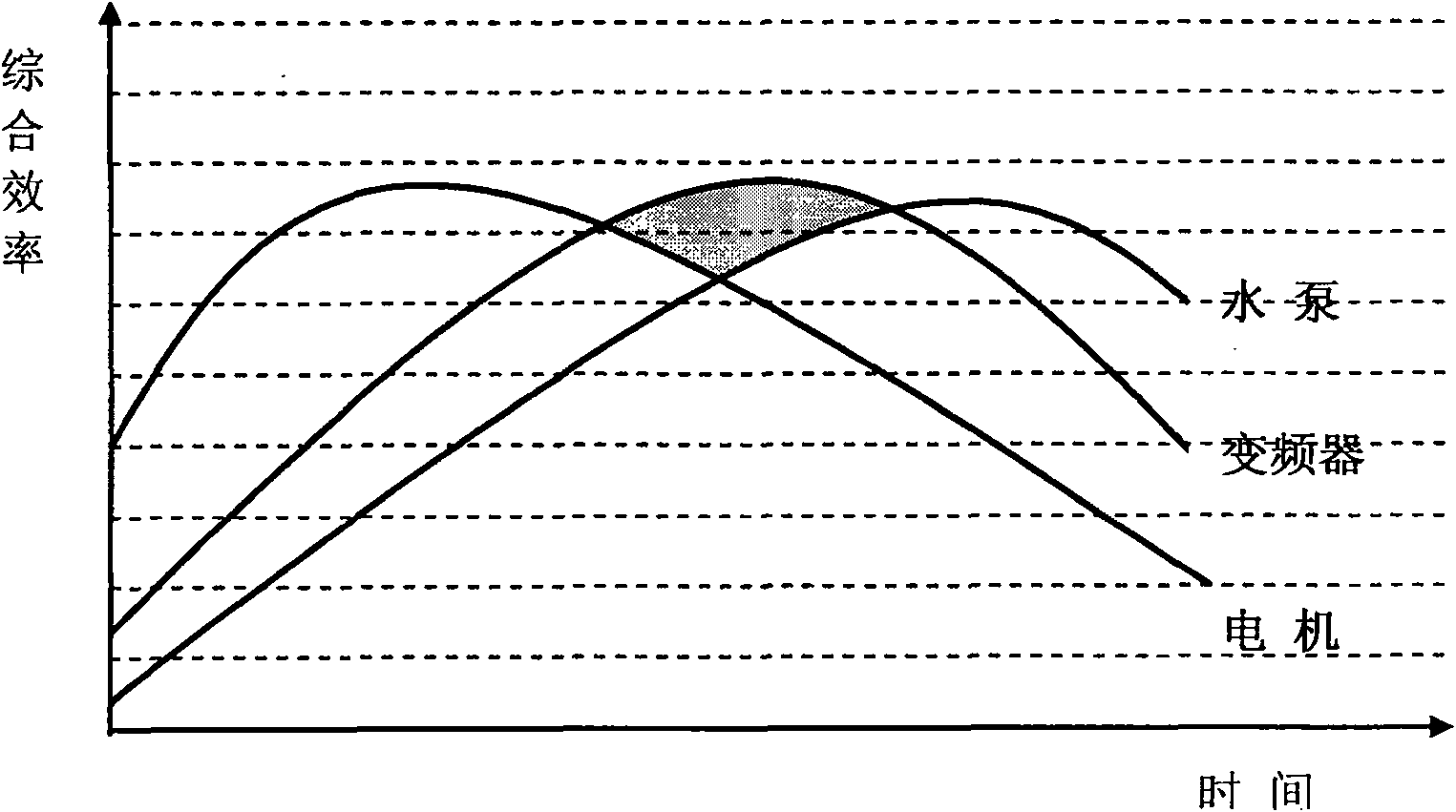

[0029] This embodiment is an optimization solution of Embodiment 1, and is an optimization of the information source in the step of collecting information described in Embodiment 1. The information originally includes the frequency converter and the calculus proportional controller PID.

[0030]The frequency converter itself can obtain some parameters of the motor and load through some of the sensors, for example, by measuring the voltage and current changes of the motor, it can indirectly measure the load driven by the motor, and also measure the voltage and current of the motor The working state of the motor can also be measured. In short, the frequency converter itself is an electrical system through which many motor-load parameters can be obtained.

[0031] Calculus proportional controller PID is a widely used controller, which is used in almost all industrial control systems. Usually, a given value is set and compared with the original value, the control direction can b...

Embodiment 3

[0033] This embodiment is an optimization solution of Embodiment 1, and is an optimization of the information source in the step of collecting information described in Embodiment 1. The information sources in the step of collecting information include external sensors that directly obtain parameters without going through the frequency converter.

[0034] Said external sensors are sensors that directly measure current, voltage, flow, speed, and the like. The setting of these sensors mainly depends on what system the final output of the power system is. For example, in an air-conditioning system, the sensor can be a sensor that directly measures the indoor temperature, or a sensor that measures the current and voltage of the refrigeration motor, or a sensor that measures the flow or velocity of the refrigerant. In short, it is a sensor that directly measures relevant system parameters. The setting of external sensors makes the whole motor, frequency converter and load system a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com