Method and system for laser detection of shape of charge level

A material surface and laser technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unsatisfactory detection accuracy and achieve the effects of reduced maintenance rate, high accuracy and simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The system and method for detecting the shape of the material surface using laser lines according to the present invention will be described in detail below by taking the material surface (usually moving) of the sintering machine as an example.

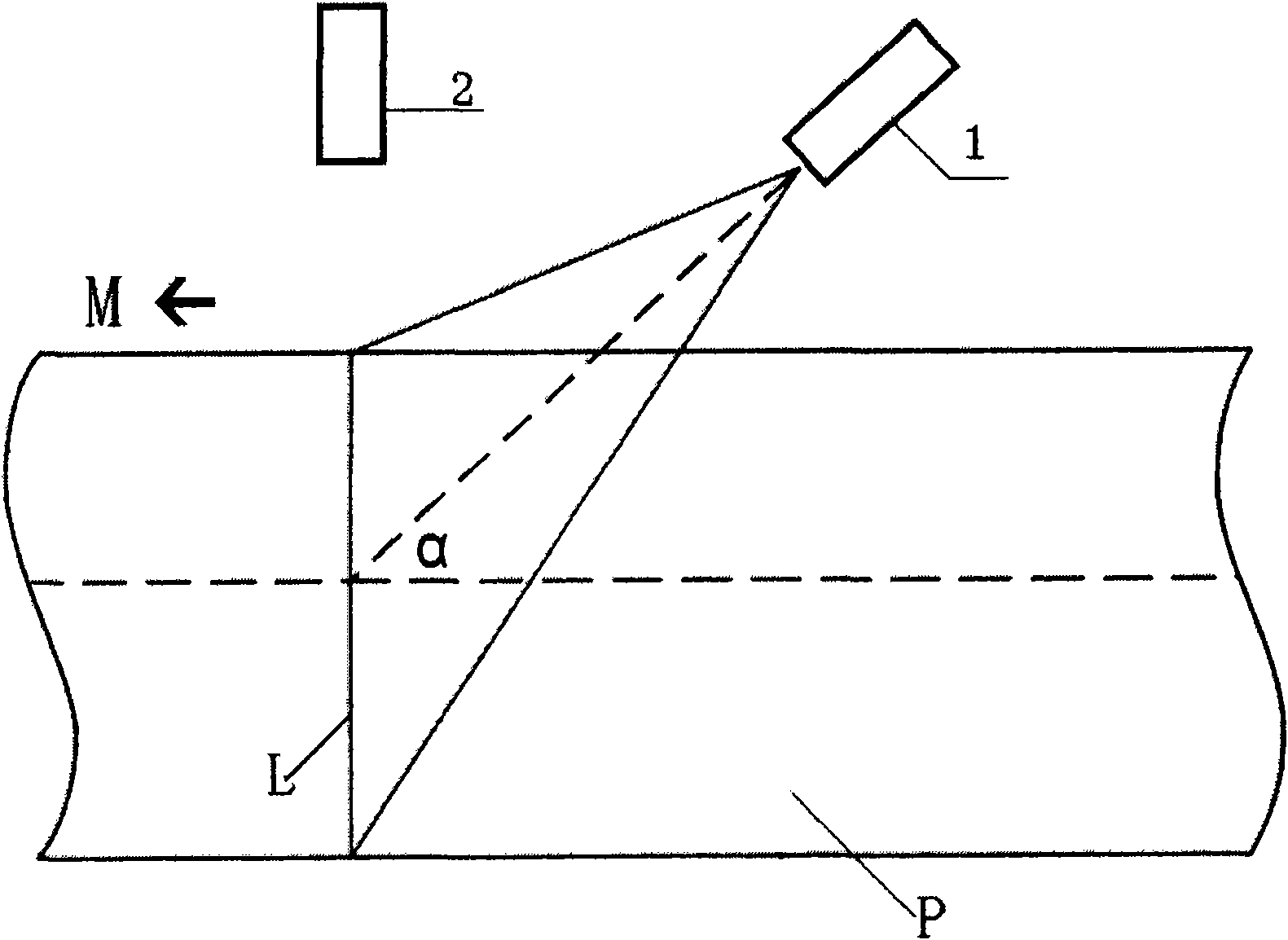

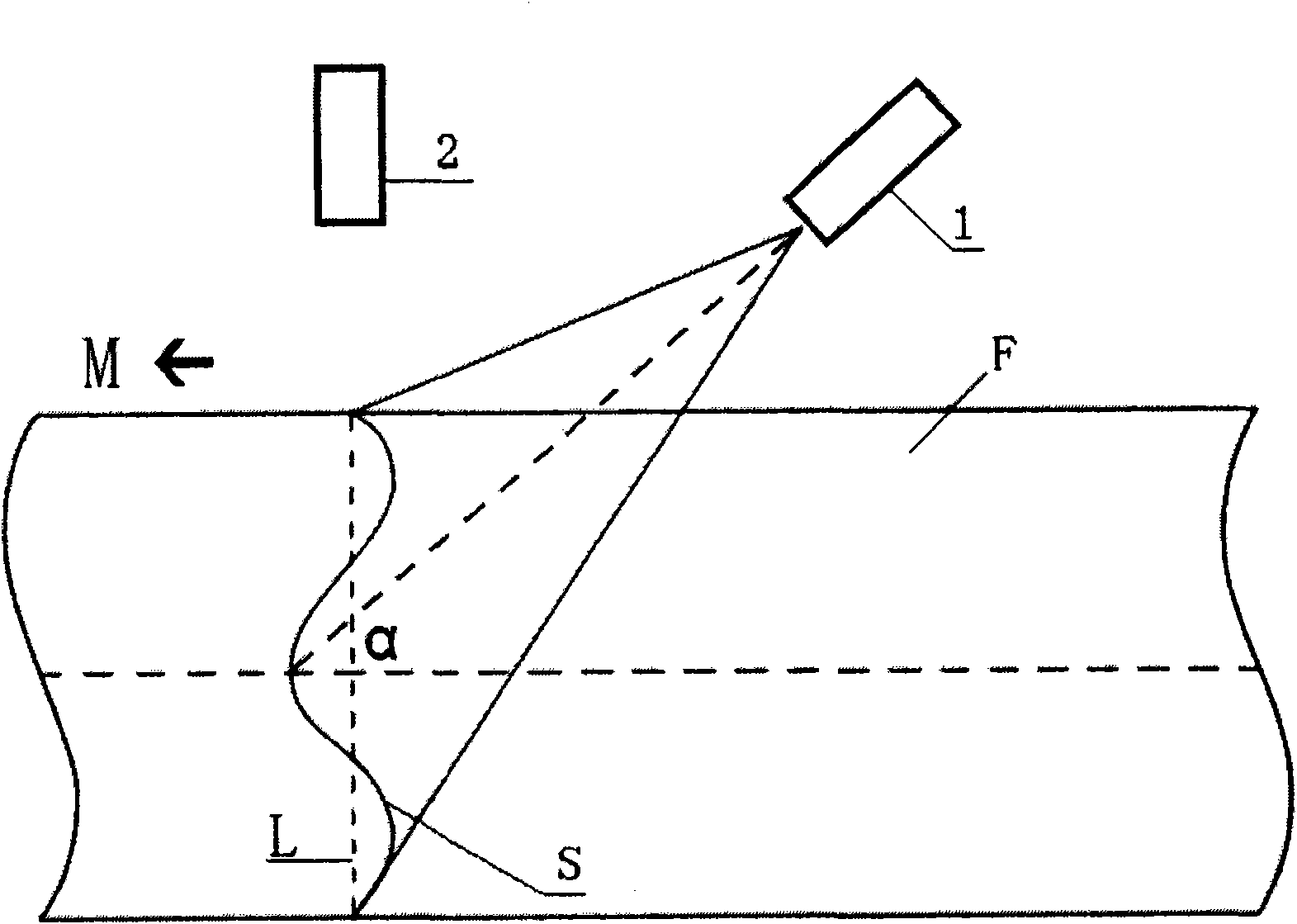

[0016] see figure 2 with image 3 , the reference plane (imaginary horizontal plane) of the material surface of the sintering machine is marked as P. The line laser 1 is positioned above the material surface, and the plane defined by the generated laser beam is parallel to the transverse direction (width direction) of the material surface and forms an angle α with the longitudinal direction M (movement direction or length direction) of the material surface. The included angle α is usually in the range of 10° to 80°, preferably around 45°. The camera 2 is positioned directly above the position (reference line L) where the laser beam generated by the online laser 1 intersects the reference plane (or reference material surface)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com