Central air conditioner and method for controlling flow of refrigerant therein

A central air conditioner and air conditioner technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems that the control accuracy is greatly affected by the ambient temperature and working conditions, affects the life of the compressor, and damages the compressor , to achieve the effects of reducing maintenance probability, stable and safe operation, and improving sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

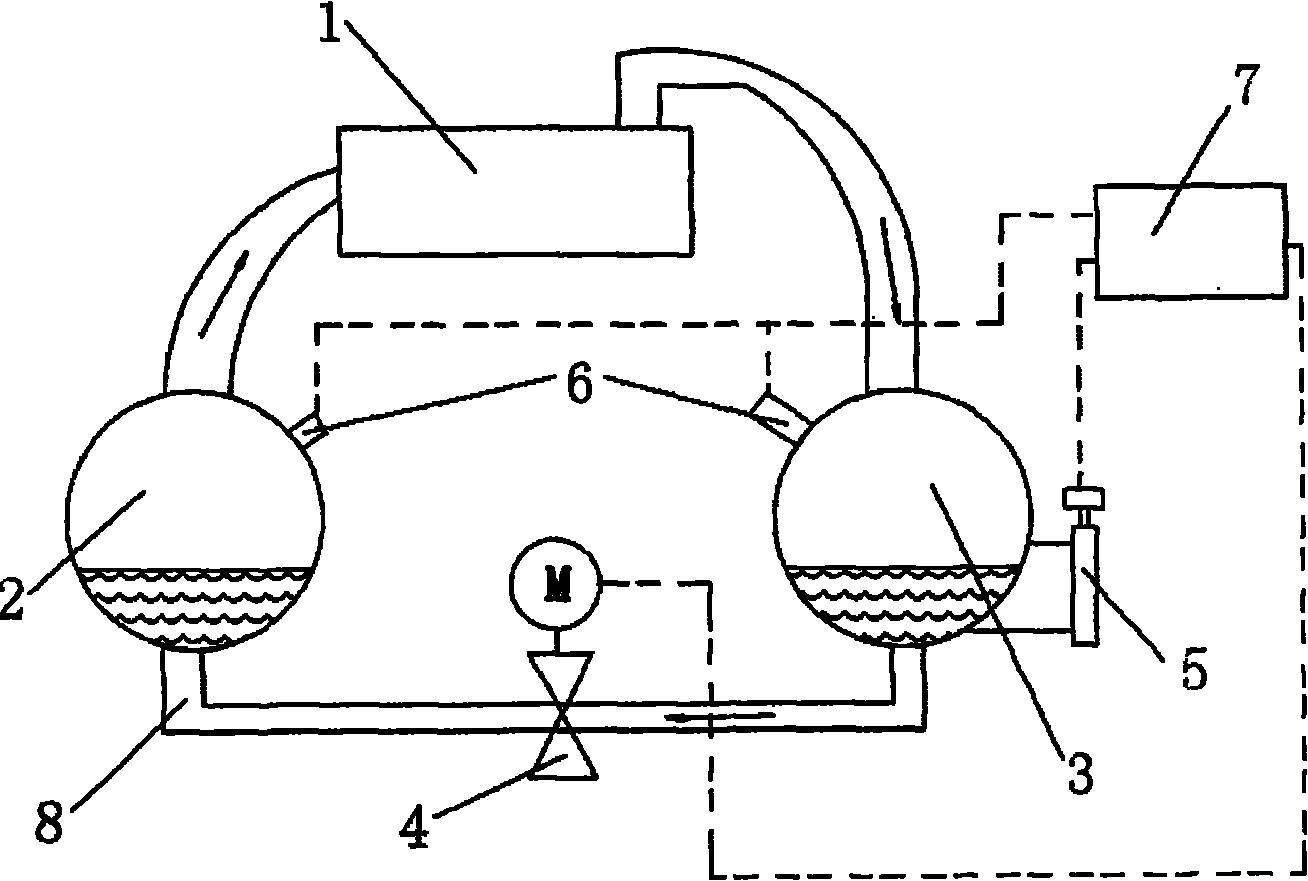

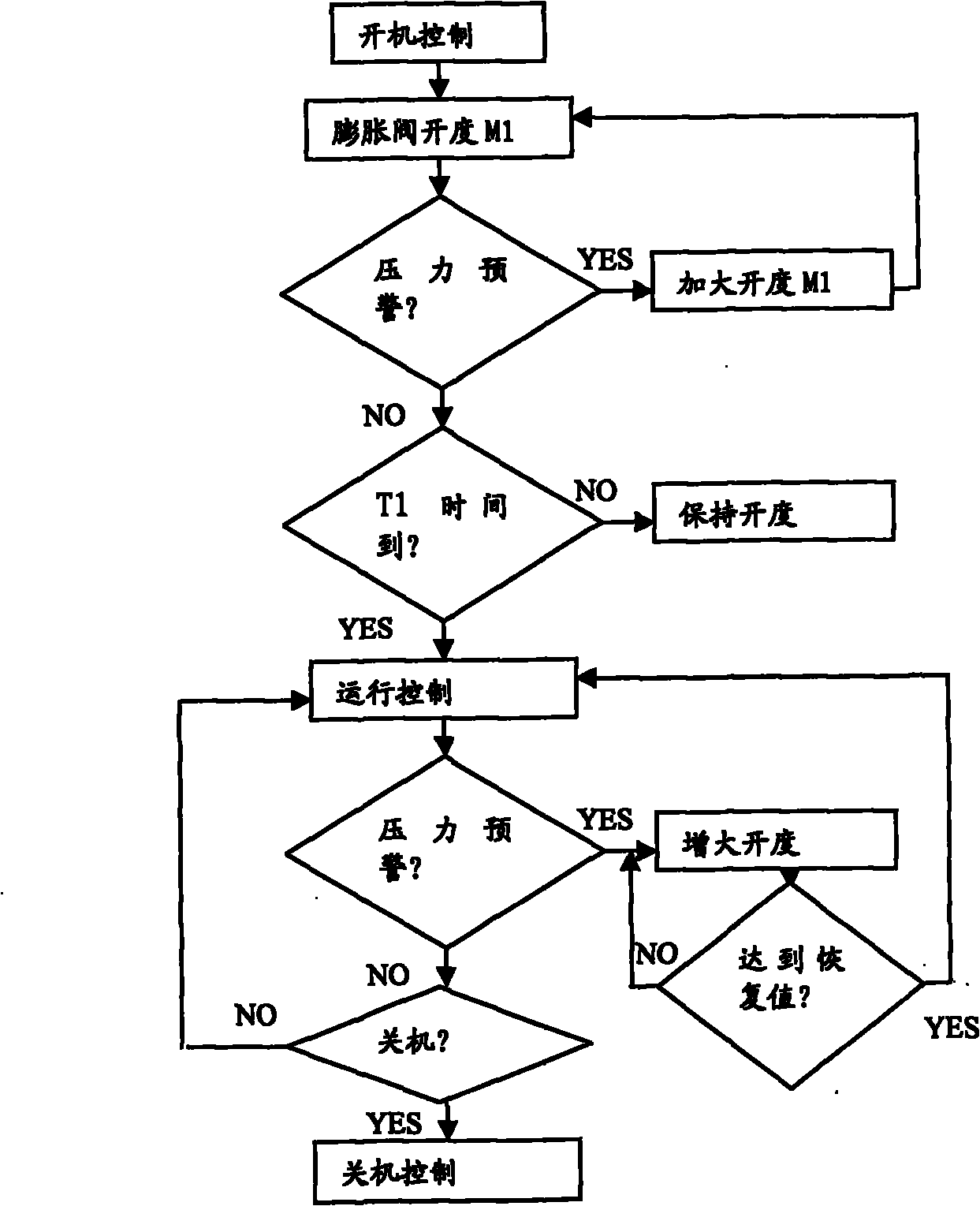

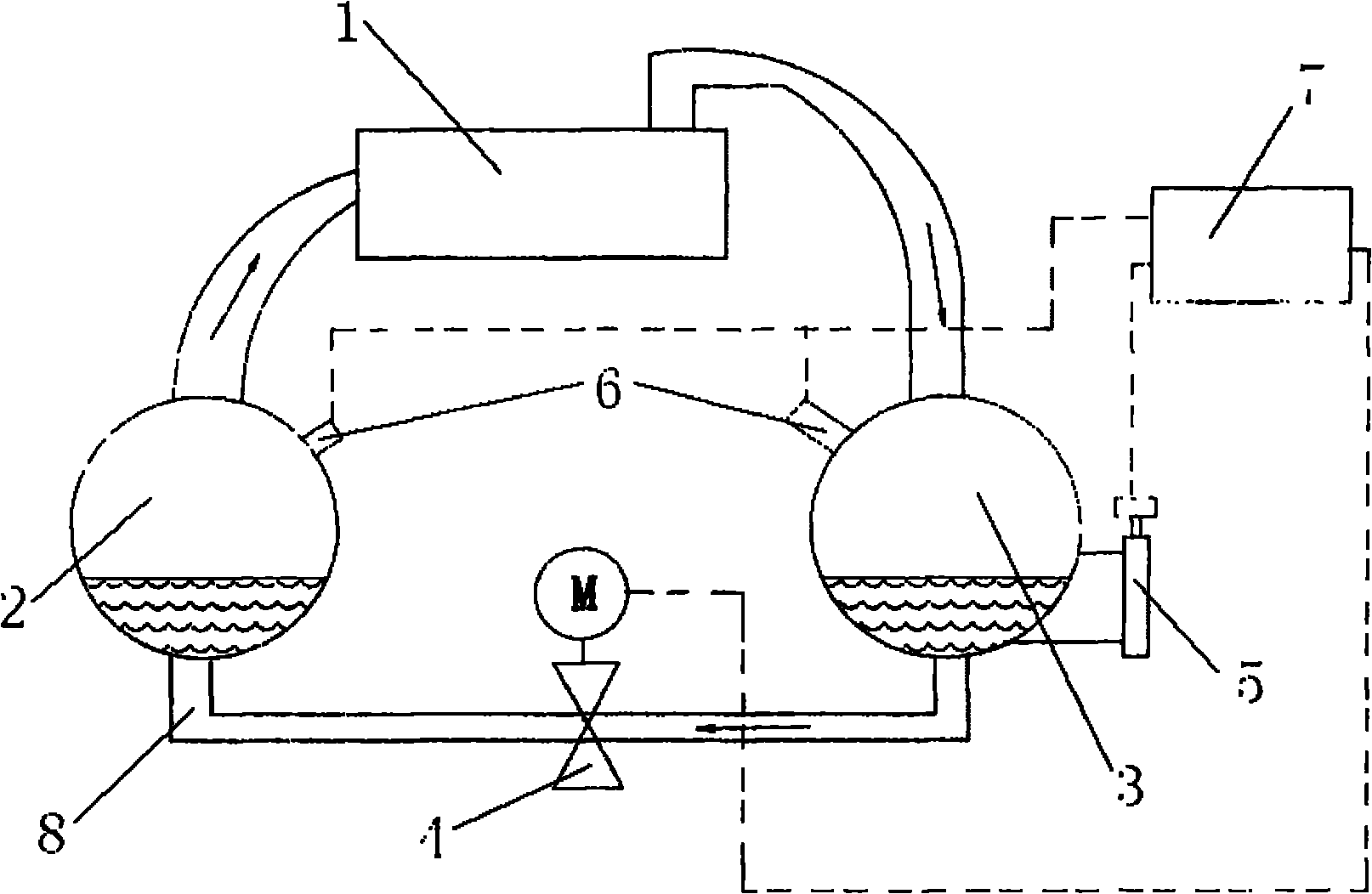

[0018] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0019] When the structure of the central air-conditioning unit and the refrigerant are fixed, the main factor affecting the heat transfer rate and energy efficiency ratio of the unit is the control of the refrigerant flow. In fact, the control of the refrigerant flow can correspond to the control of the refrigerant liquid level (liquid level) in the evaporator and condenser. Because the higher the suction superheat, the lower the liquid level of the refrigerant in the evaporator, and it is necessary to increase the opening of the electronic expansion valve to increase the flow of refrigerant. In this way, the liquid level of the refrigerant increases while the superheat is reduced On the contrary, when the suction superheat degree is low, the opening degree of the electronic expansion valve is reduced to reduce the refrigerant flow rate, and the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com