Environment-friendly smoke denitrification and desulfurization equipment

A technology for environmental protection equipment and dust, which is applied in separation methods, transportation and packaging, and separation of dispersed particles. It can solve the problems of high infrastructure investment costs and low enthusiasm, and achieve the effects of improving purification efficiency and effect, delaying speed, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

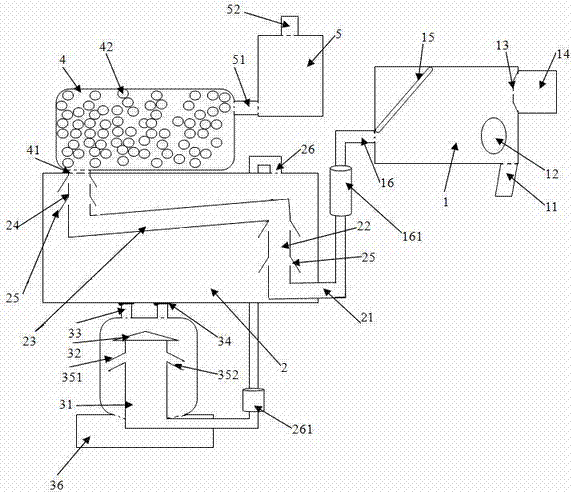

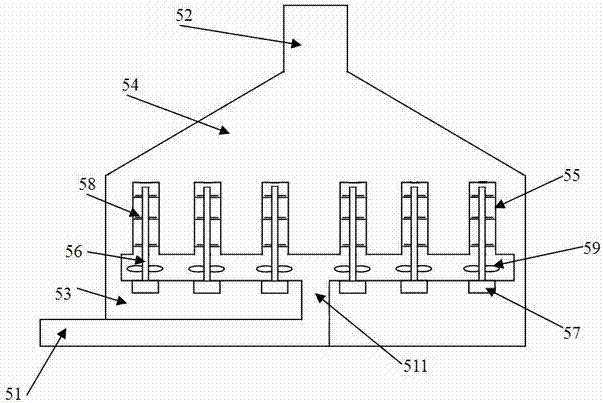

[0031] An environmental protection equipment for smoke and dust denitrification and desulfurization, comprising an oxidation chamber, a denitrification chamber, a sewage treatment chamber, a desulfurization chamber and a bag filter.

[0032] The oxidation chamber includes an oxidation chamber casing, a smoke inlet, an arc guide, an ozone nozzle, an ozone generator, an inclined deflector, and an oxidation chamber smoke outlet; the oxidation chamber casing is a rectangular parallelepiped structure, with A soot inlet for introducing soot is provided. The soot inlet is inclined to the bottom of the oxidation chamber shell, and the inclination direction is that the top faces the right inner side wall of the oxidation chamber shell. Arc-shaped flow guide, the arc-shaped flow guide is an elliptical cylinder arranged horizontally, the outer arc on the right side is tangent to the leftmost vertical line at the top of the dust inlet, and is on the right inner side of the oxidation chambe...

Embodiment 2

[0044] An environmental protection equipment for smoke and dust denitrification and desulfurization, comprising an oxidation chamber, a denitrification chamber, a sewage treatment chamber, a desulfurization chamber and a bag filter.

[0045] The oxidation chamber includes an oxidation chamber casing, a smoke inlet, an arc guide, an ozone nozzle, an ozone generator, an inclined deflector, and an oxidation chamber smoke outlet; the oxidation chamber casing is a rectangular parallelepiped structure, with A soot inlet for introducing soot is provided. The soot inlet is inclined to the bottom of the oxidation chamber shell, and the inclination direction is that the top faces the right inner side wall of the oxidation chamber shell. Arc-shaped flow guide, the arc-shaped flow guide is an elliptical cylinder arranged horizontally, the outer arc on the right side is tangent to the leftmost vertical line at the top of the dust inlet, and is on the right inner side of the oxidation chambe...

Embodiment 3

[0056] An environmental protection equipment for smoke and dust denitrification and desulfurization, comprising an oxidation chamber, a denitrification chamber, a sewage treatment chamber, a desulfurization chamber and a bag filter.

[0057] The oxidation chamber includes an oxidation chamber casing, a smoke inlet, an arc guide, an ozone nozzle, an ozone generator, an inclined deflector, and an oxidation chamber smoke outlet; the oxidation chamber casing is a rectangular parallelepiped structure, with A soot inlet for introducing soot is provided. The soot inlet is inclined to the bottom of the oxidation chamber shell, and the inclination direction is that the top faces the right inner side wall of the oxidation chamber shell. Arc-shaped flow guide, the arc-shaped flow guide is an elliptical cylinder arranged horizontally, the outer arc on the right side is tangent to the leftmost vertical line at the top of the dust inlet, and is on the right inner side of the oxidation chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com