Process method for cogenerating electricity, charcoal, heat and fertilizer through gasified gas supply of biomass

A process method and biomass technology, applied in the direction of gasification process, chemical industry, spiral gasifier, etc., can solve the problems of poor economic benefit, single process product, and high oxygen content requirements, and achieve the benefits of large-scale production, The effect of improving economic efficiency and wide adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

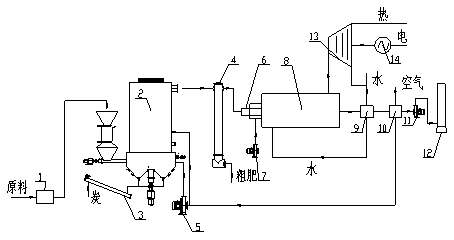

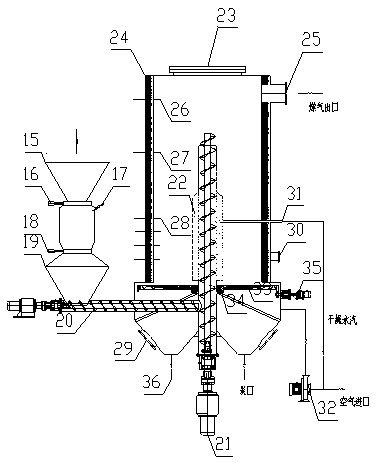

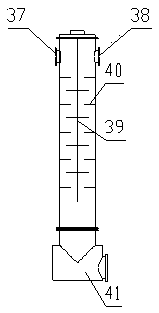

[0025] Control attached figure 1 , taking wood raw material as an example: the sliced raw material is pretreated 1 (sliced to about 6 cm with a drum slicer), the elevator enters the gasification device 2 at 600-800 °C for oxidation-reduction reaction, and the blower 5 blows the gas from the gas The gasification device 2 blows in hot air from the air preheater 10 and dry water vapor from the furnace, and generates hot gas after gasification (the temperature of the hot gas is 200-300°C containing extract, tar, and dust). Preliminary filtration of dust in the gas is achieved by passing through the raw material layer under positive pressure, and then undergoes preliminary gravity sedimentation in the crude manure collector 4, and the heavy tar and extract are trapped in the crude manure collector. The biomass produced in the lower part of the gasification device 2 The charcoal is collected by spiral cooling of the inner shaft and shell of the conventional equipment, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com