Method for removing surface dust of mask plate

A mask plate and fine dust technology, which is applied in the field of dust removal on the surface of the mask plate, can solve the problems of damage to the mask protective film 2, not increasing the blowing pressure, and damage to the mask plate 1, so as to reduce the risk of damaging the mask plate, Improve dust removal efficiency and remove charged dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

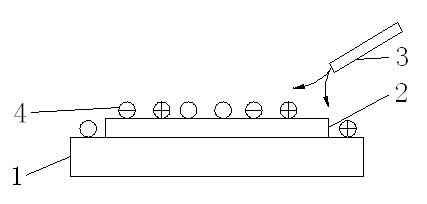

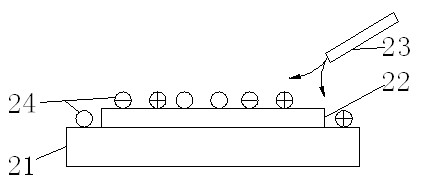

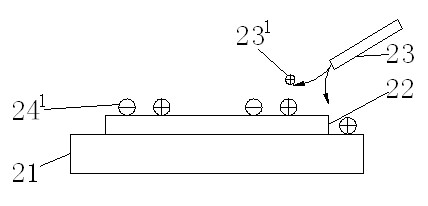

[0027] Such as Figure 2-5 As shown, the present invention provides a method for removing fine dust on the surface of a mask plate, which includes the following steps:

[0028] First, adjust the blowing air pressure of the blowing air gun 23 according to the air pressure value of the mask plate 21 and the mask protective film 22 on it, and blow the mask plate 21 and the mask protective film 22 to remove the air pressure on the mask plate 21 and the mask protective film 22 Part of the dust 24, at this time, the gas blown out by the blowing air gun 23 is air or nitrogen.

[0029] After the blowing air gun 23 blows air for a period of time, under the condition that the blowing air pressure remains unchanged, the gas blown out by the blowing air gun 23 is generally manually converted into a gas with positive ions to neutralize the adsorption on the mask plate. 21 and the negatively charged dust 24 on the mask protection film 22 1 Electricity, so that it is blown away from the ma...

Embodiment 2

[0034] Such as Figure 6 As shown, at first, adopt the same steps as in Embodiment 1, adjust the blowing air pressure of the air-blowing air gun 33 according to the air pressure value that the mask plate 31 and the mask protective film 32 on it bear, to the mask plate 31 and the mask The mold protection film 32 is blown to remove part of the dust 34 thereon. At this time, the gas blown out by the blowing air gun 33 is air or nitrogen.

[0035] After the blowing air gun 33 blows air for a period of time, under the condition that the blowing air pressure remains unchanged, the polarity of the residual charged dust particles on the surface of the mask plate 31 and the mask protective film 32 is detected by the charge test sensor 35; Such as Figure 7 As shown, if it is detected that the residual charged dust particles on the surface of the mask plate 31 and its mask protection film 32 are negative ion dust particles 34 1 , then the gas blown out of the air-blowing air gun 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com