Optical lens surface dust cleaning apparatus and dust collection method

A technology for optical lenses and dust removal devices, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems of time-consuming and laborious, secondary pollution of optical lens surfaces, etc. , The effect of cleaning dust thoroughly and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

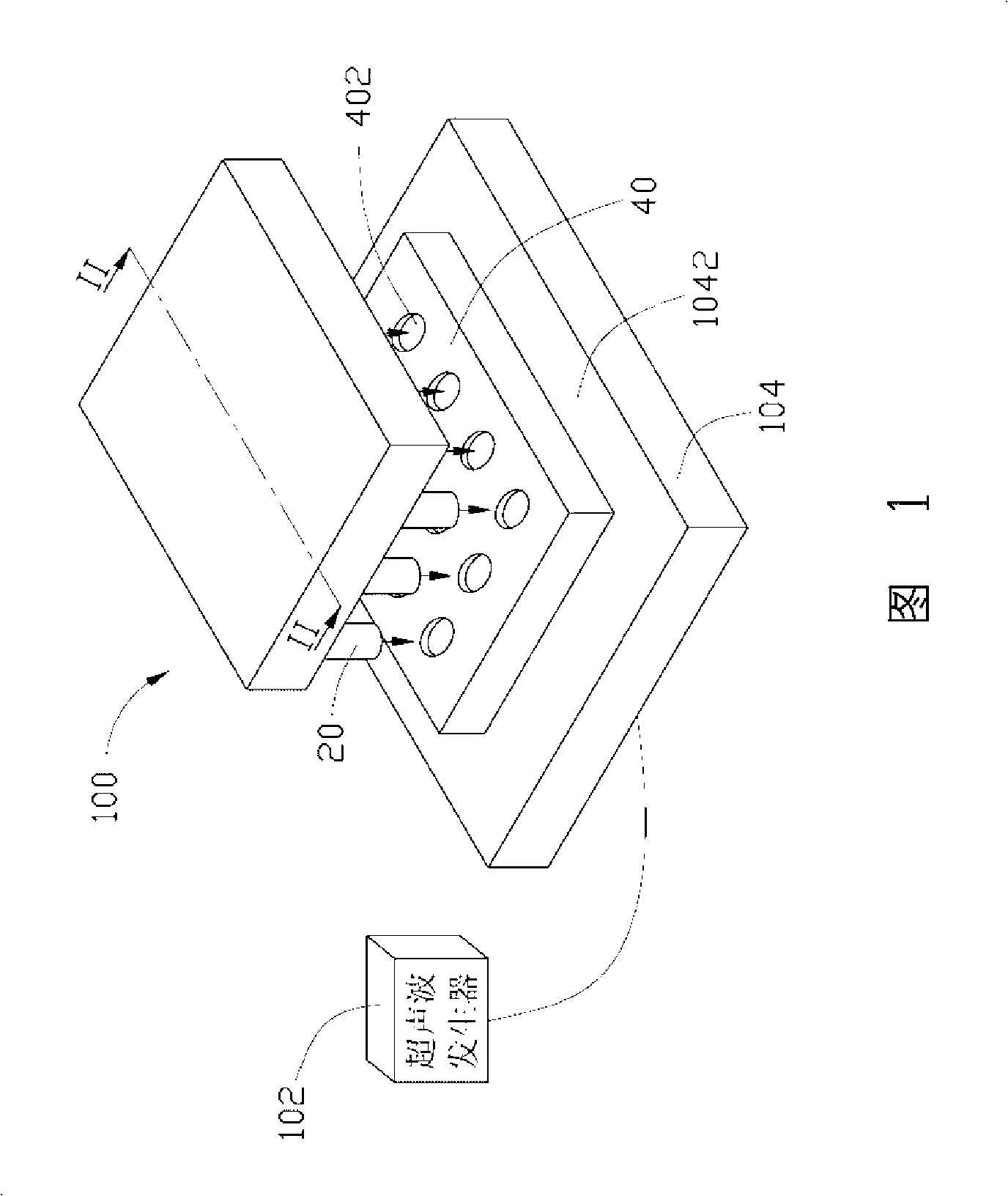

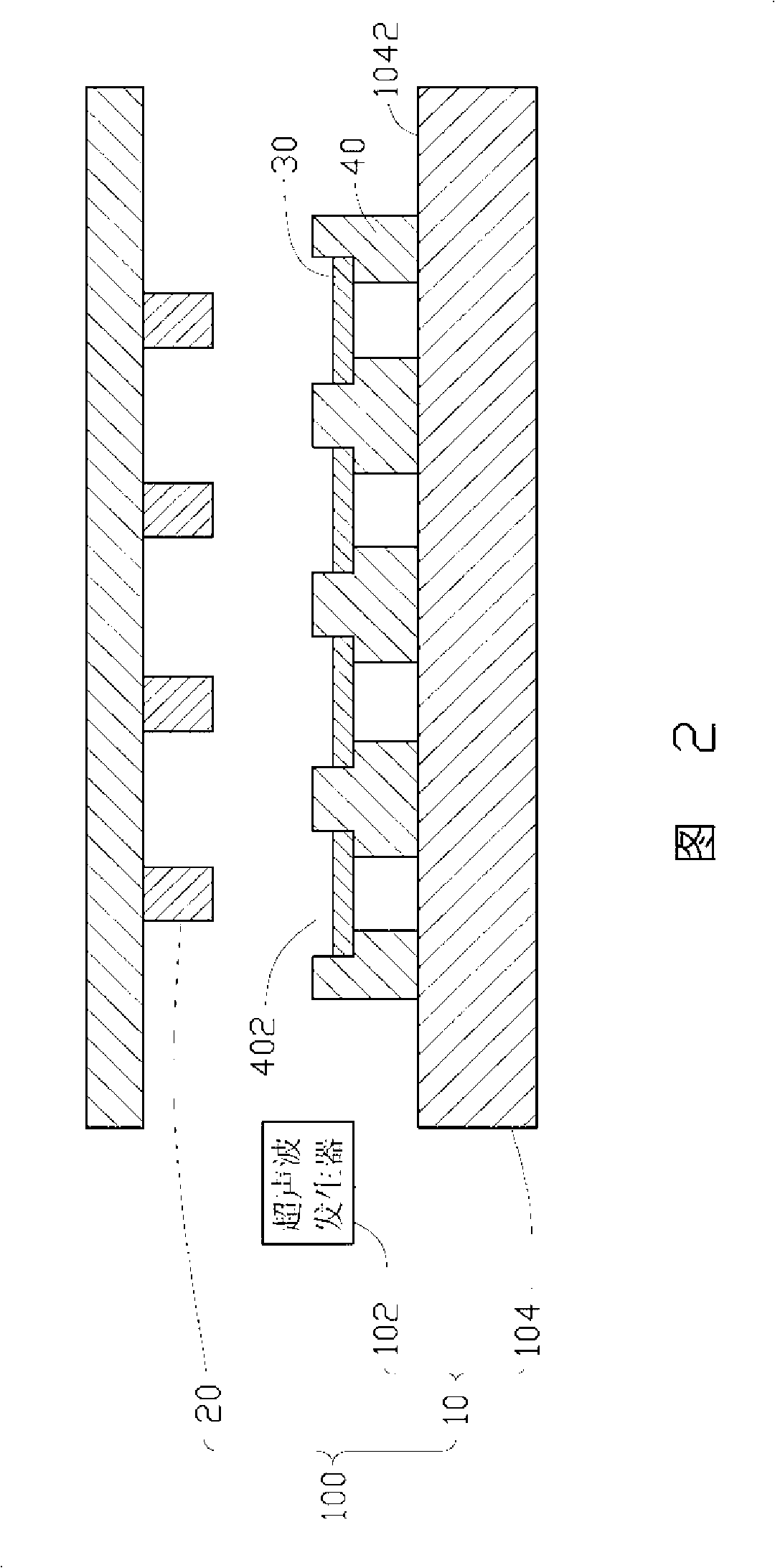

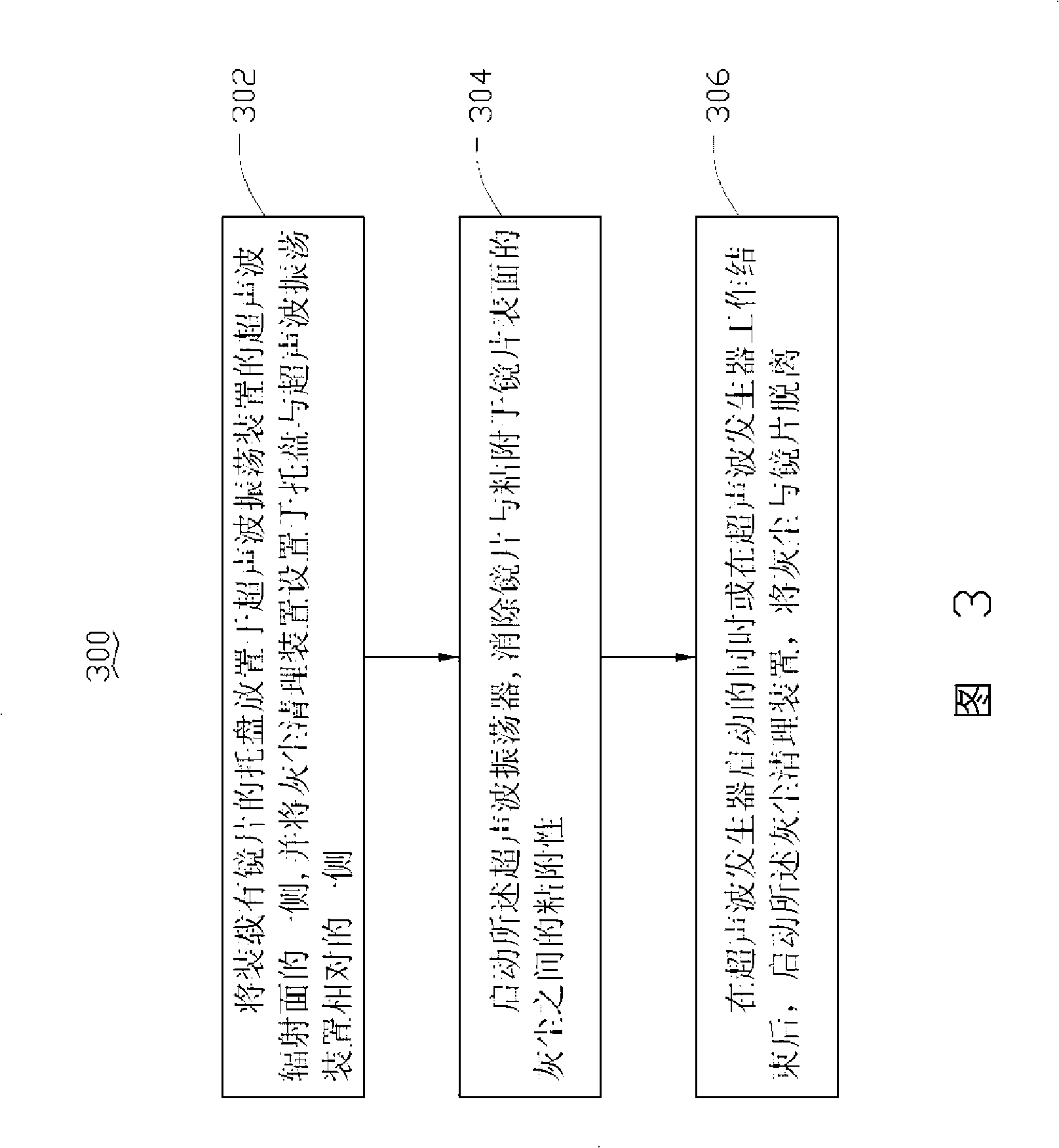

[0014] Please refer to Fig. 1 and Fig. 2, it is the optical lens surface dedusting device 100 of the first embodiment of the present invention, the optical lens surface dedusting device 100 of the present invention is applied in the assembly process of the lens module, can be applied to the optical lens has not been assembled into The stage of the lens barrel can also be applied to the stage where the optical lens has been assembled in the lens barrel. The optical lens surface dust removal device 100 includes an ultrasonic oscillator 10 and a dust cleaning device 20 . In this embodiment, a tray 40 carrying a plurality of optical lenses 30 is disposed on the surface of the ultrasonic oscillator 10 , and the dust cleaning device 20 is disposed on a side of the tray 40 opposite to the ultrasonic oscillator 10 . The optical lenses 30 are disposed in the componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com