Fabric surface dust removal device

A technology for dust removal devices and fabrics, which is applied in the directions of removing smoke and dust, cleaning flexible items, chemical instruments and methods, etc., can solve the problems of fabric wrinkles, difficult to meet process requirements, and unsatisfactory effects, and achieves the best dust removal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

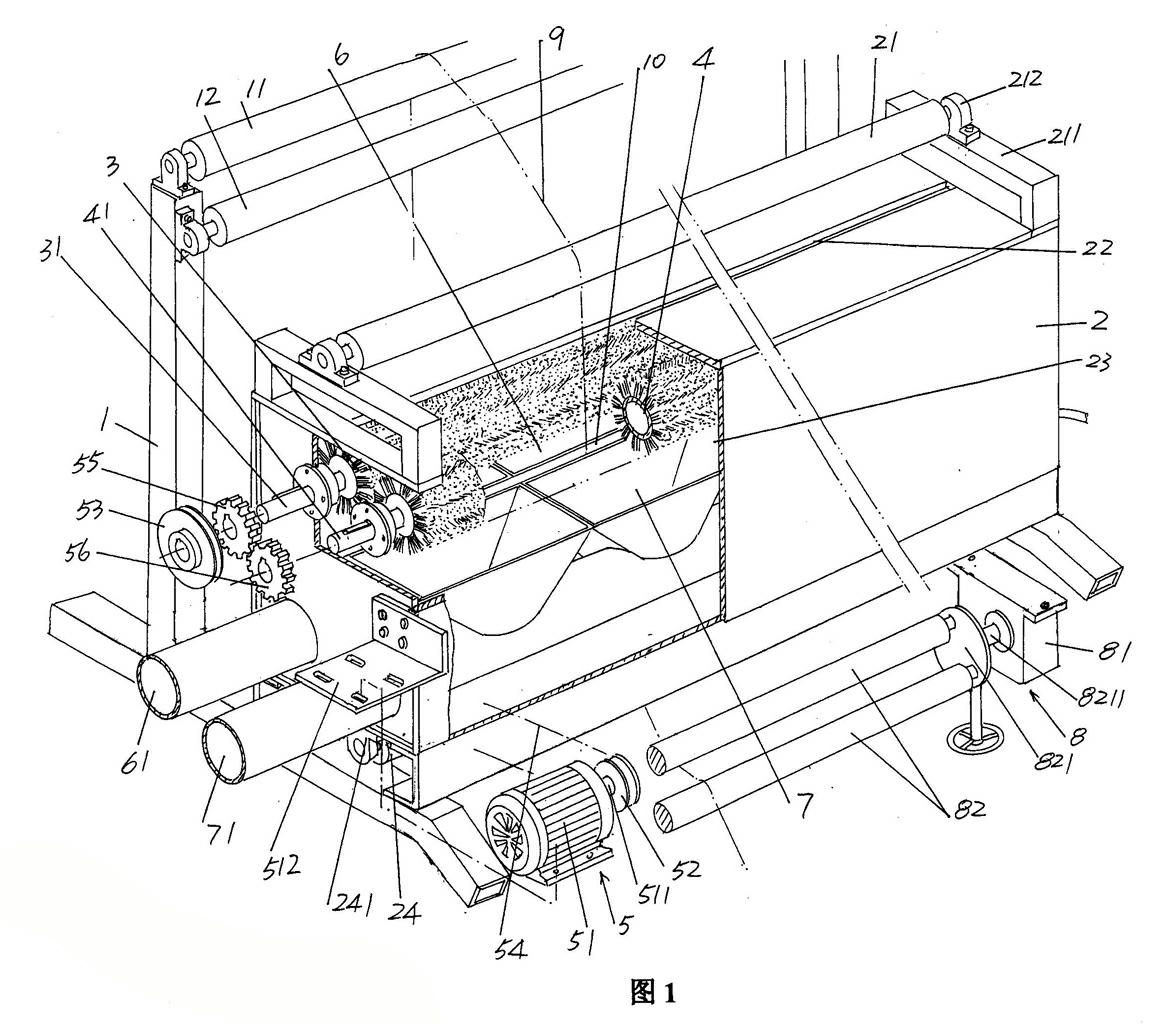

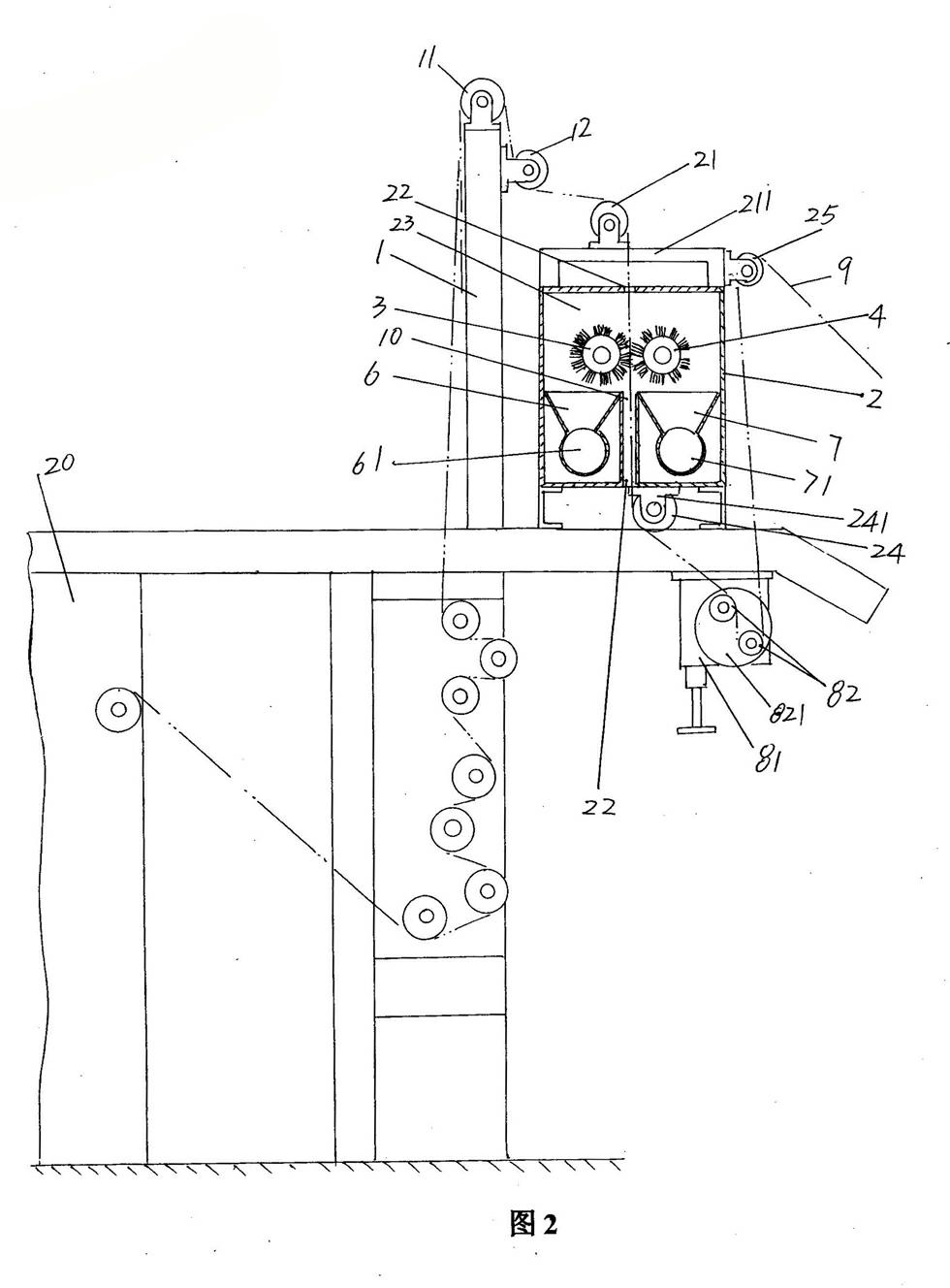

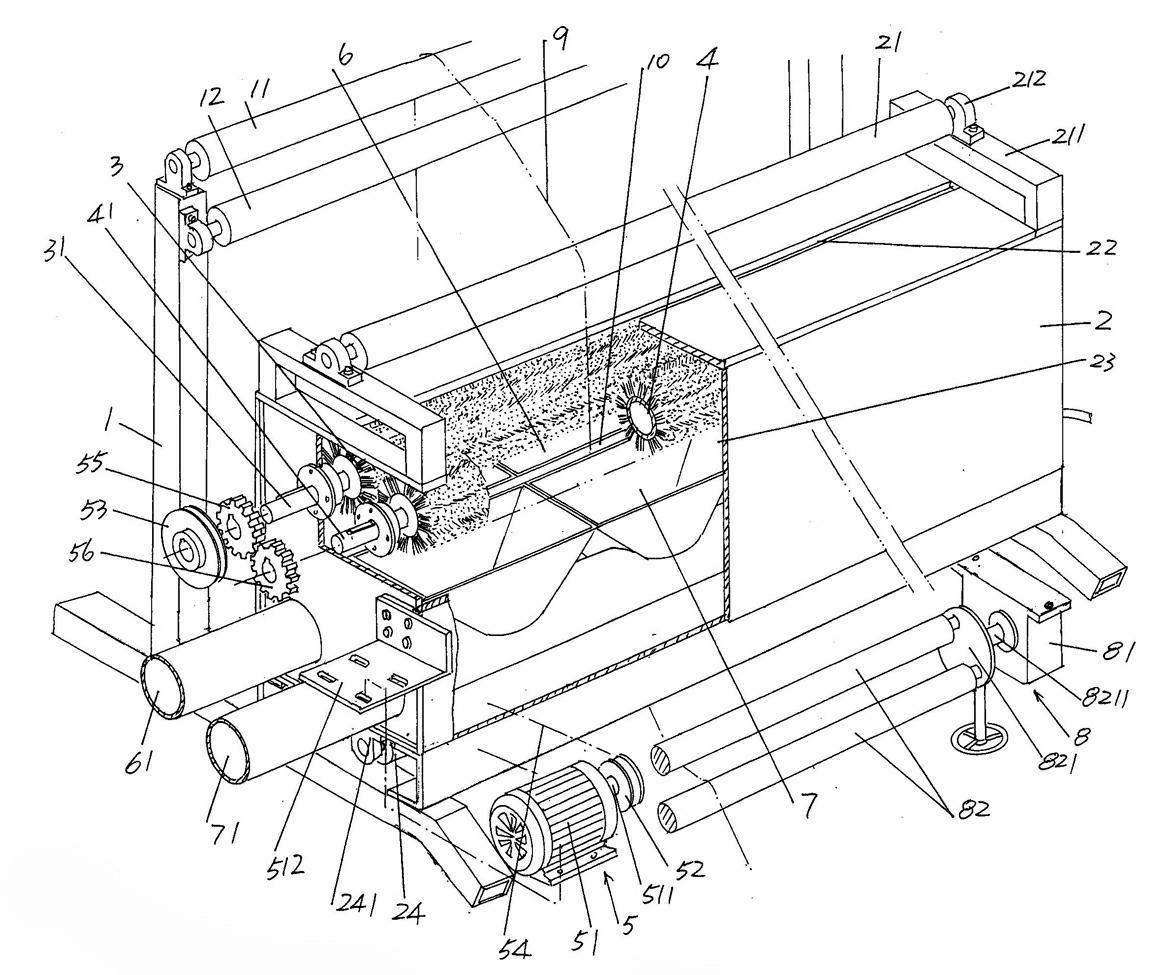

[0017] please see figure 1 , provides a frame 1, on the top of the frame 1, a first cloth guide roller 11 and a second cloth guide roller for guiding the fabric to a subsequent process such as a gluing process are arranged rotatably through a shaft seat 12. A dust removal box body 2 is fixed on the frame 1, and a dust removal fabric lead-out roller 21 is arranged on the top of the dust removal box body 1 by means of a pair of brackets 211 in an empty state. As shown in the figure, the dust removal fabric lead-out roller 21 is rotatably supported on the aforementioned bracket 211 through a pair of bearing seats 212 . A cloth guide groove 22 for passing the fabric 9 is formed in the middle part of the length direction of the dust removal box body 2 , and a fabric introduction roller 24 is rotatably arranged at the bottom of the dust removal box body 2 through a pair of roller shaft seats 241 .

[0018] see you later figure 1 , a first brush roller 3 and a second brush r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com