Liquid-level electrostatic precipitator

A technology of electrostatic precipitator and electrostatic generator, which is applied in the direction of external electrostatic separator, electrostatic separation, electrode structure, etc., can solve the problems of complex adsorption electrode structure of electrostatic precipitator, affecting the continuous operation of the factory, inconvenient dust cleaning, etc. To achieve the effect of continuous factory operation, simple operation and efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

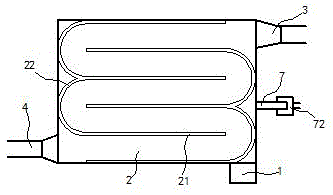

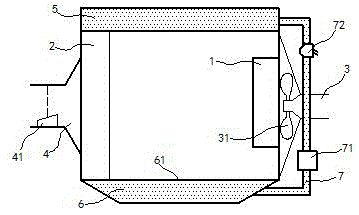

[0014] exist figure 1 , figure 2 In the shown embodiment, the liquid surface electrostatic precipitator includes an electrostatic generator 1, an air inlet 3, a dust removal chamber 2 and an exhaust port 4; a liquid storage chamber 5 is installed on the top of the dust removal chamber 2, and The liquid storage chamber 5 is filled with dust removal liquid; a dust collection chamber 6 is installed at the bottom of the dust removal chamber 2, and the dust collection chamber 6 and the dust removal chamber 2 are separated by a dust collection mesh plate 61; Dust removal plates 21 are arranged parallel and equidistant in the dust removal chamber 2, and each dust removal board 21 is vertically fixed in the dust removal chamber 2; each dust removal board 21 is connected by arc-shaped tiles 22 and assembled into a serpentine channel; dust removal The upper end of the plate 21 runs through the bottom of the liquid storage chamber 5 and extends into the dust removal liquid, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com