Full-automatic paint spraying production line for furniture plates

A production line, fully automatic technology, applied in the direction of coating, spray booth, spraying device, etc., can solve the problems of panel paint spraying, such as uncompact rhythm, inconsistent process rhythm, waste of time and personnel, etc., to ensure the quality of paint spraying, The effect of continuous production cycle and reduction of paint waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

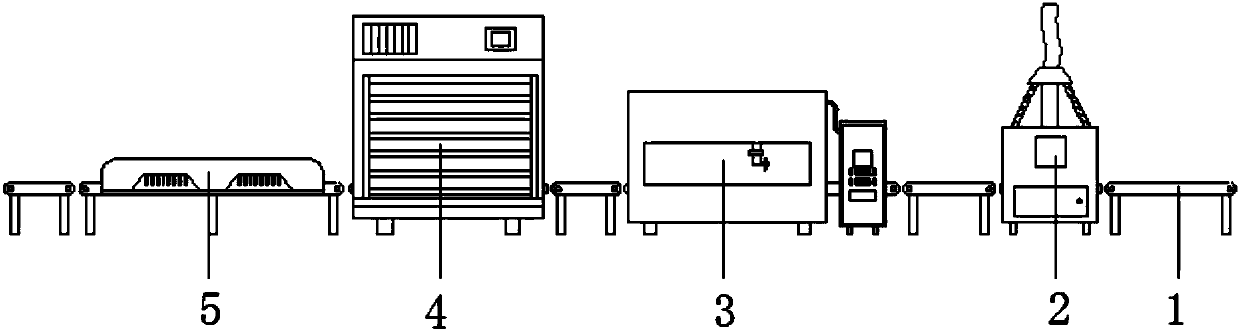

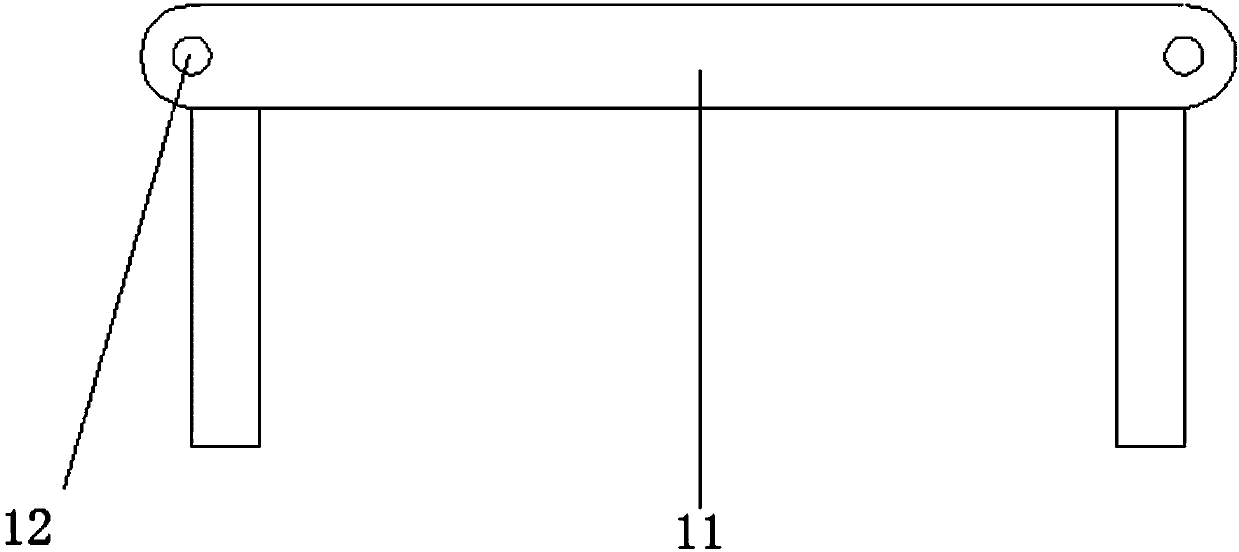

[0035] A fully automatic paint spraying production line for furniture panels, such as figure 1 As shown, it includes a dust removal device 2, a paint spraying device 3, a primary drying device 4 and a secondary drying device 5 connected in sequence, and the production line is provided with a belt conveyor 1 for transporting furniture panels 6, such as figure 2 As mentioned above, throughout the entire assembly line, including the belt 11 and the driving roller 12 for driving the belt 11 to rotate, the furniture board 6 successively passes through the dust removal device 2 to remove surface dust, sprays paint through the paint spraying device 3, and passes through the primary drying device 4 to solidify and bake. dry, and finally further cured and dried by the secondary drying device 5, and the whole paint spraying process is completed automatically.

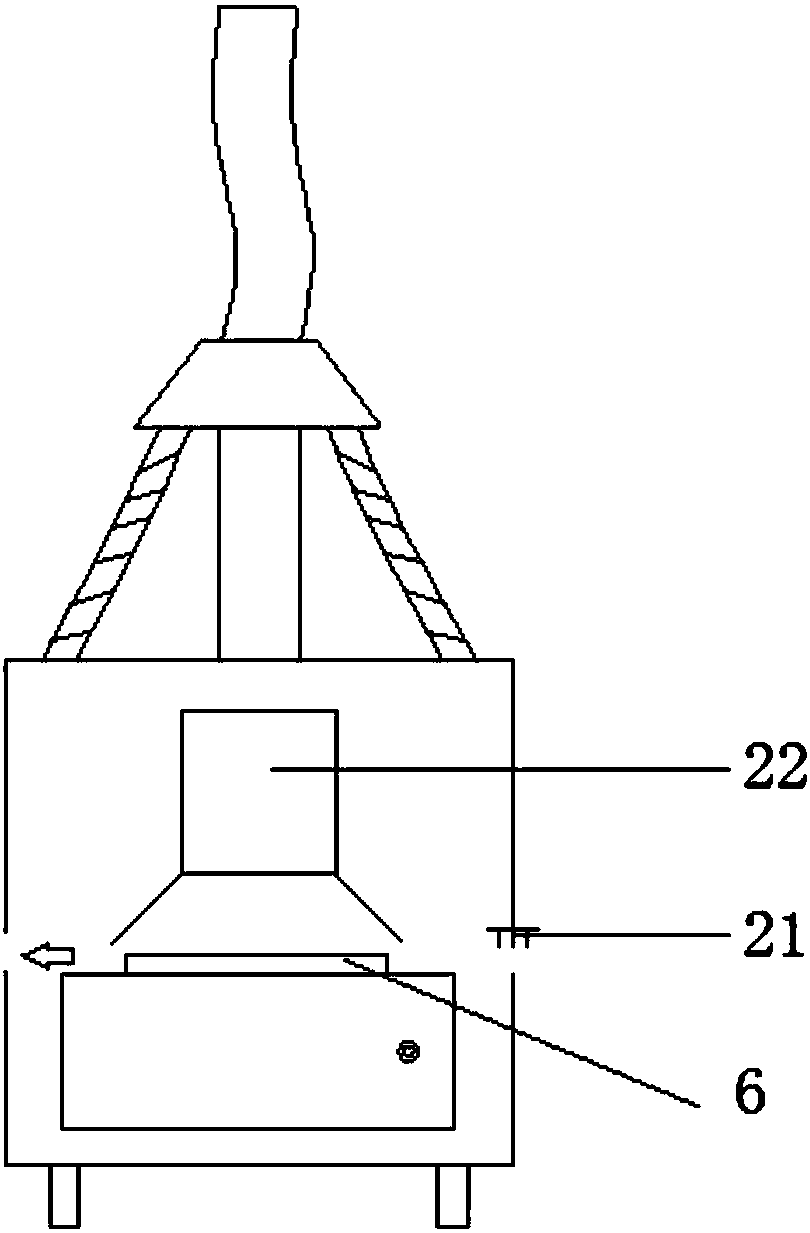

[0036] Specifically, such as image 3 The inside of the dust removal device 2 is provided with a vacuum cleaner 22, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com