Patents

Literature

107results about How to "Food hygiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

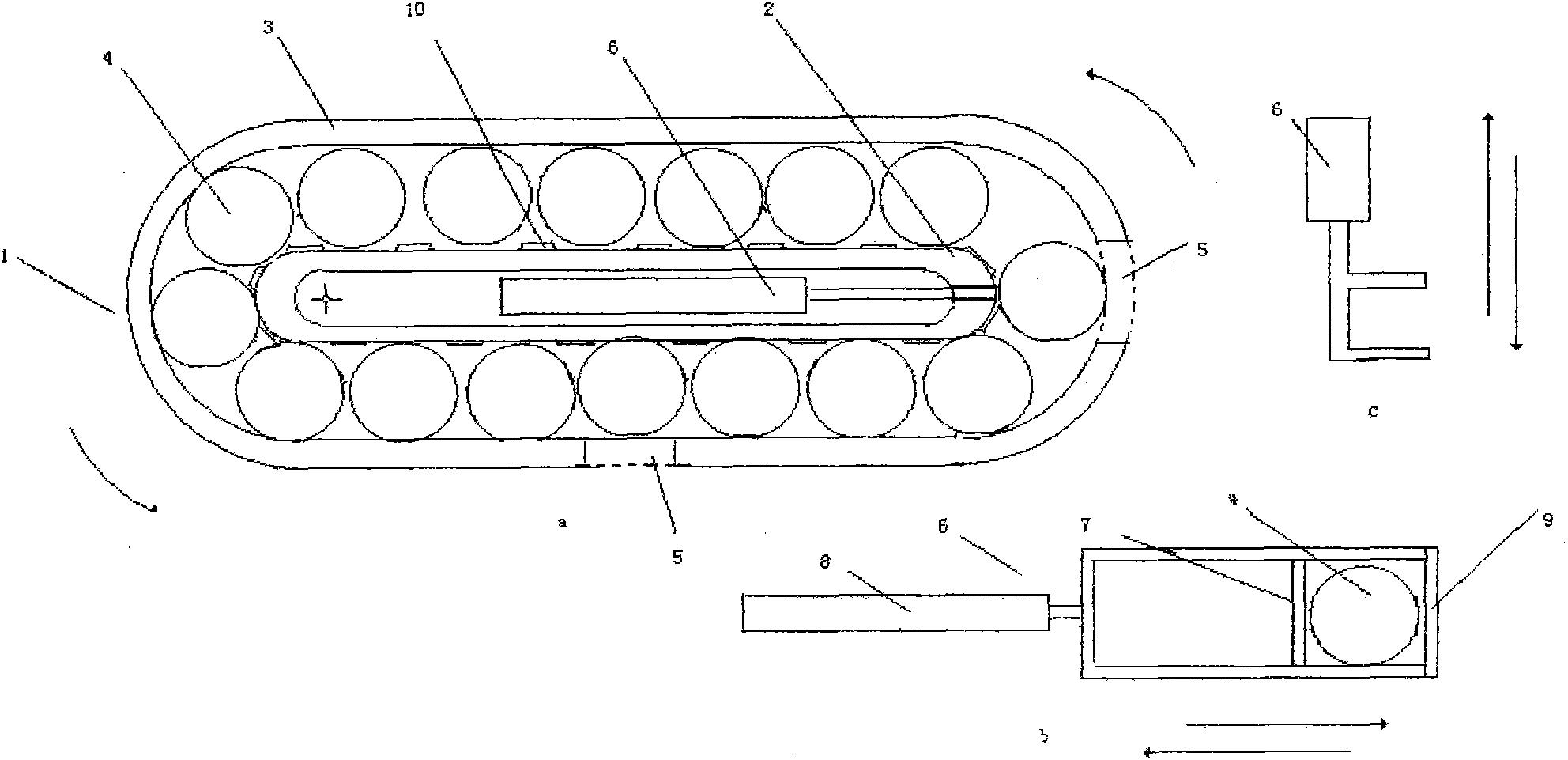

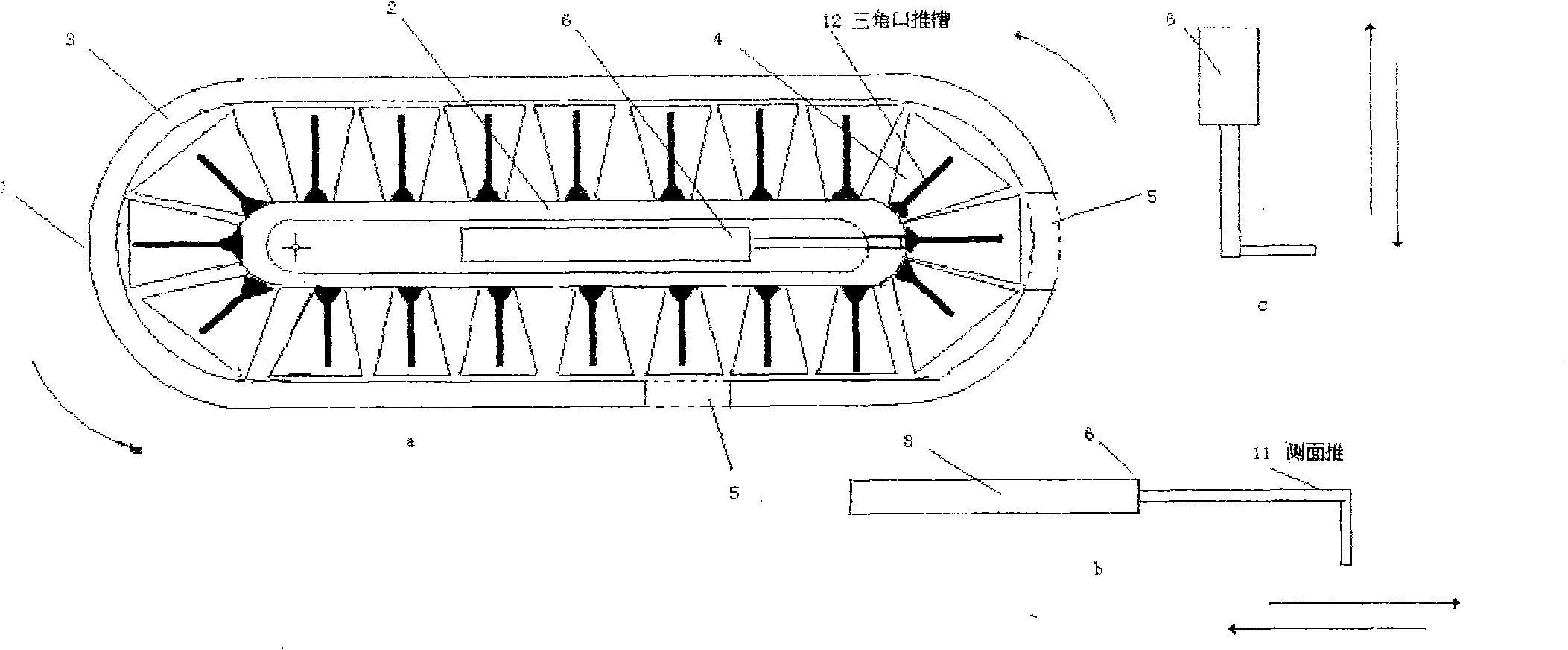

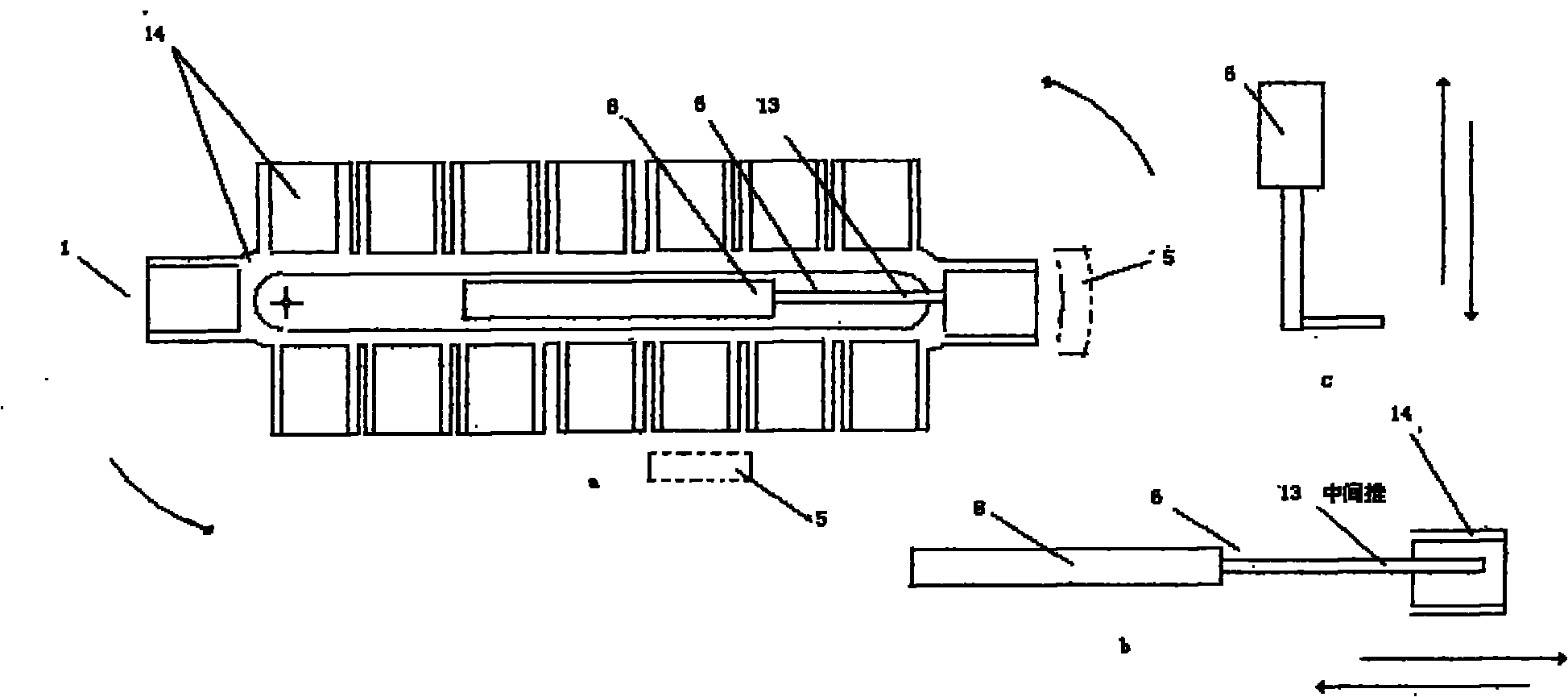

Vending machine capable of cyclically conveying commodity

InactiveCN102467776AEasy to buyFood hygieneCoin-freed apparatus detailsApparatus for dispensing discrete articlesProcess engineeringConveyor belt

For a vending machine used in the prior art, commodities can only be sequentially taken out. Therefore, a conveyor belt which can be stopped at a designated position is used for replacing a device for taking out and placing the commodities in the prior art, operation surfaces and commodity displaying surfaces are added on a plurality of surfaces of a cubic or rectangular solid vending machine, and the side surface of a cylindrical vending machine is divided into a plurality of user operation surfaces and commodity displaying surfaces.

Owner:李笑非

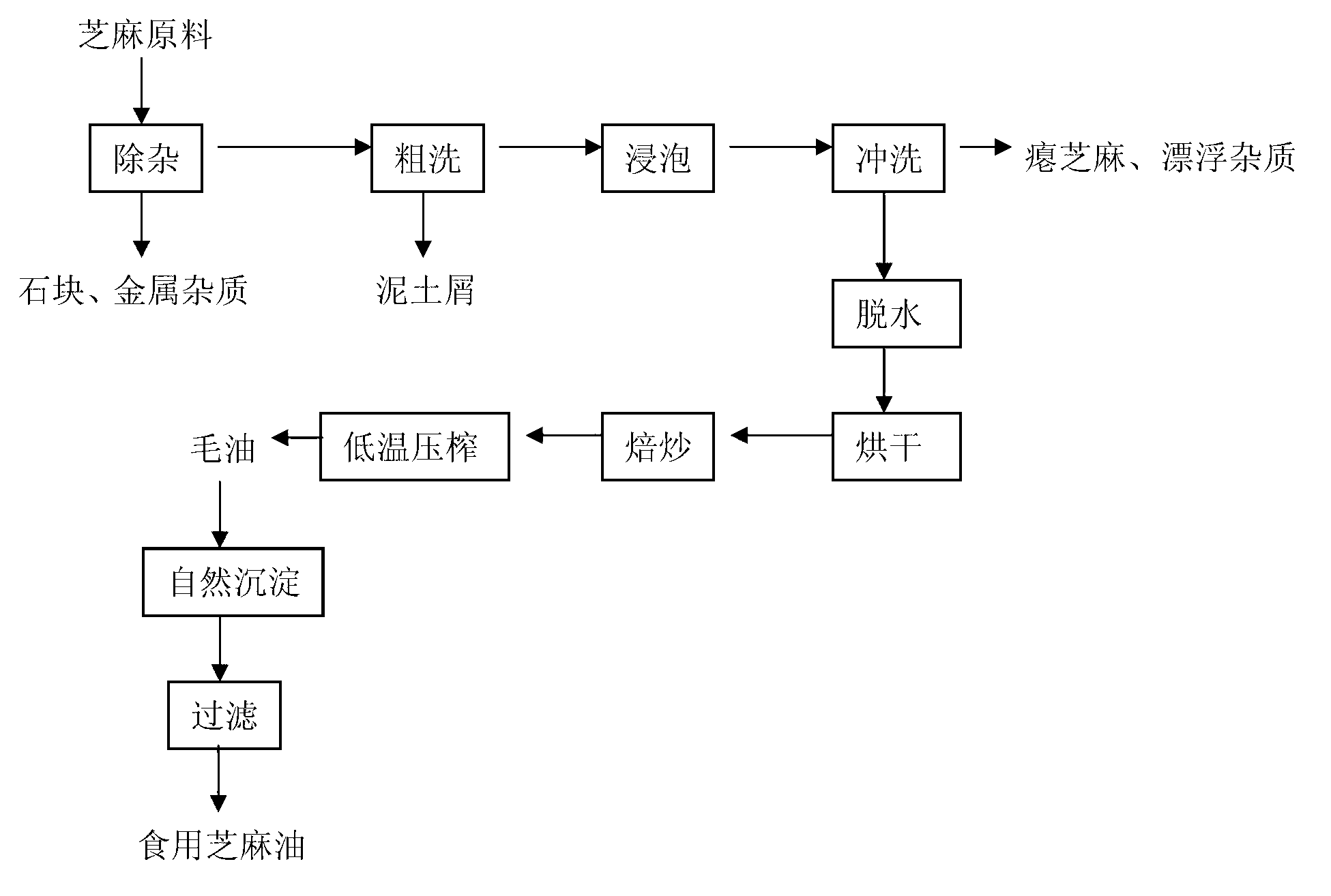

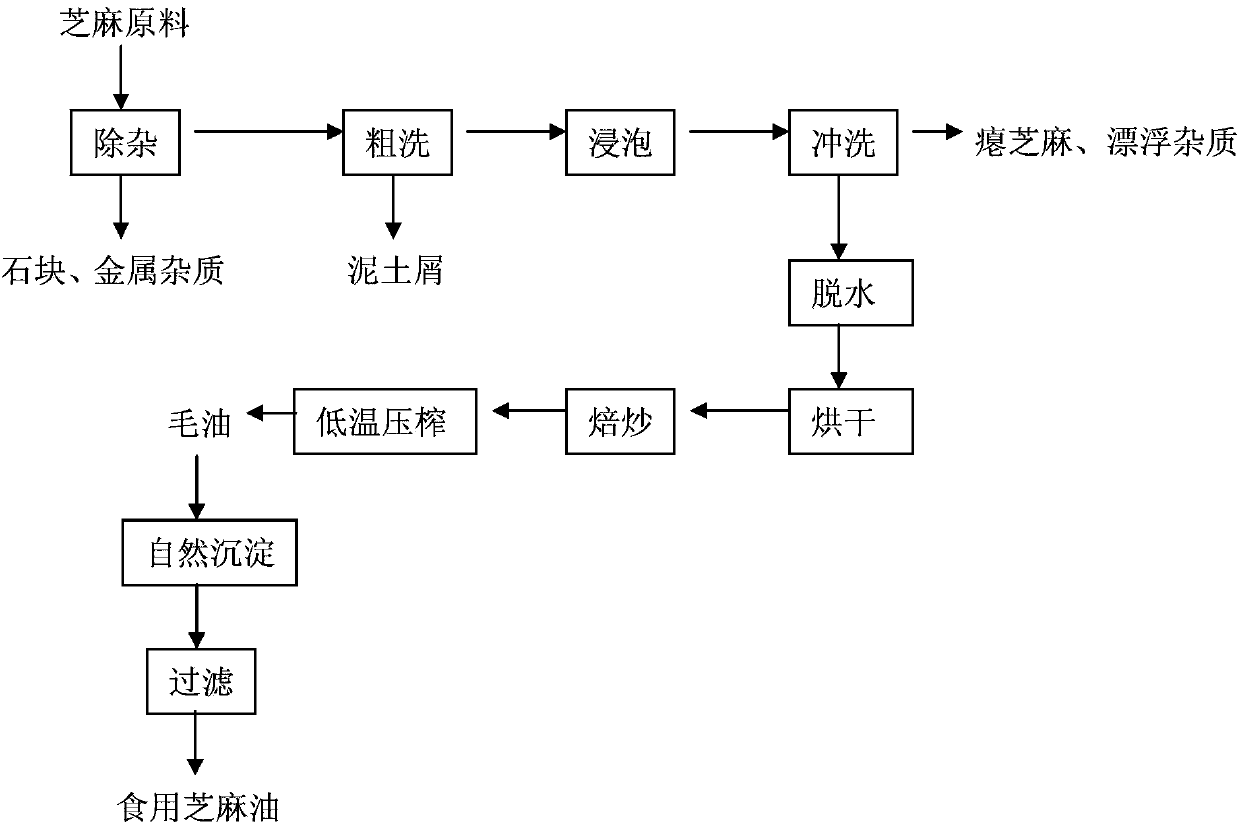

Process for preparing sesame oil

The invention relates to a process for preparing sesame oil. The process comprises the following steps of: removing impurities from sesame serving as a raw material, roughly washing the sesame, immersing and flushing the sesame, dehydrating and drying the sesame until the water content is reduced to 4.5 to 7wt%, then baking until the water content is reduced to below 2.5wt%, squeezing by a vertical type hydraulic squeezing machine at low temperature to obtain oil, and performing natural sedimentation and filtration on the squeezed rough oil to obtain the edible sesame oil. The technical steps are reasonable; the process is easy to operate; the prepared sesame oil has no rich sesame oil flavor; the flavor is natural and pure; the gloss is clear and crystal; the taste is mellow; and the original essence in the sesame can be retained to the maximum extent.

Owner:SHANGHAI LIANGYOU GRP +2

Wheat germ protein beverage and preparation method thereof

ActiveCN102008109AWide variety of sourcesLow costFood preparationMilk substitutesNutrientSodium cyclamate

The invention discloses a wheat germ protein beverage, which is prepared from the following raw materials in percentage by mass: 2 to 10 percent of wheat germ, 0.5 to 5 percent of peanuts, 0.1 to 2 percent of whole milk or whole milk powder, 0.001 to 0.2 percent of vanillin, 0.001 to 0.5 percent of wheat essence, 0.05 to 5 percent of stabilizing agent, 0 to 10 percent of white granulated sugar orcane sugar, 0 to 0.3 percent of sodium cyclamate or aspartame or stevioside, and the balance of water. The wheat germ protein beverage can be digested and absorbed easily, has rich nutrients, pure and rich flavor and sweat taste, and is unique; and the preparation method is simple, the process is strict and orderly, the raw materials have wide sources, and the cost is low.

Owner:晨光生物科技集团天津有限公司

Preparation technology for beef balls

The invention relates to a preparation technology for beef balls, which is characterized by comprising the following steps: (1) preprocessing: selecting and cleaning fresh rump steak and fresh chicken breast, wherein the weight ratio of the fresh rump steak to the fresh chicken breast is (3:1)-(3:2); (2) curing: curing the obtained beef and chicken in an aqueous solution of prickly ash and nitrite for 1-1.5 h at 0-4 DEG C; (3) meat grinding; (4) chopping and mixing; (5) beef ball shaping: extruding meat paste manually or mechanically into beef balls with diameters of 2-2.5 cm; (6) cooking and cooling; (7) vacuum packing and then sterilizing; (8) fast freezing. The preparation technology provided by the invention can be used for producing beef balls which contain rich nutrient substances, high-quality animal protein, mineral substances, vitamins and various amino acids necessary for human bodies, and the beef balls are convenient, fast, safe and sanitary to eat and are not required to be secondarily processed.

Owner:王婵

Production process for sweet potato vermicelli

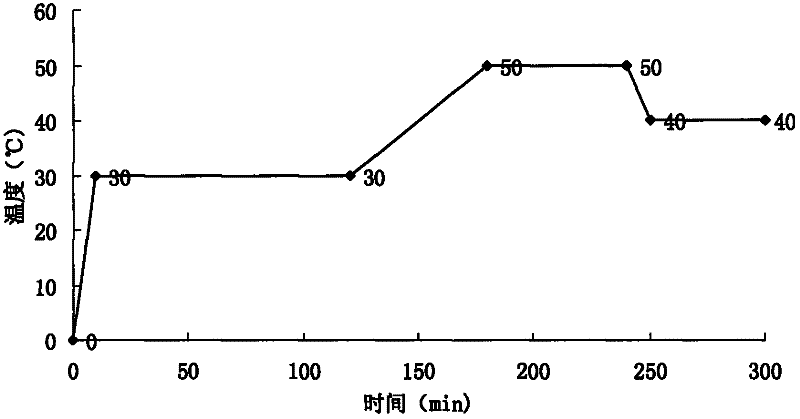

The invention relates to a production method for sweet potato vermicelli. The production process for sweet potato vermicelli comprises the processes of slurrying, forming, peel cooking, ageing, shredding and drying, wherein the slurrying process comprises the following steps: 1) preparing a cooked paste, namely, placing 2-3% of the total of starch in a basin, adding running water or warm water and uniformly stirring, then adding boiling water occupying 2-3% of the total of starch, rapidly stirring to a thick paste, and naturally cooling to 40-50 DEG C; 2) slurrying, namely, pouring the prepared and cooled cooked paste in a mixing-stirring bucket, adding water and uniformly stirring, then continuously adding the remainder starch in the mixing-stirring bucket, and adding water and uniformly stirring simultaneously; and 3) vacuumizing, namely, pumping the paste prepared in the step 2) in a slurry storage tank by a vacuum pump, vacuumizing, then opening a discharge valve of the slurry storage tank, and discharging to a forming mechanism. According to the production method for sweet potato vermicelli, which is disclosed by the invention, the produced vermicelli is good in impression, boilproof and not liable to break through the vacuumizing treatment in the slurrying process; moreover, other auxiliary materials such as alums and edible gum are not used in the production process, thus guaranteeing the safety and sanitation of the vermicelli.

Owner:河南新天豫食品有限公司

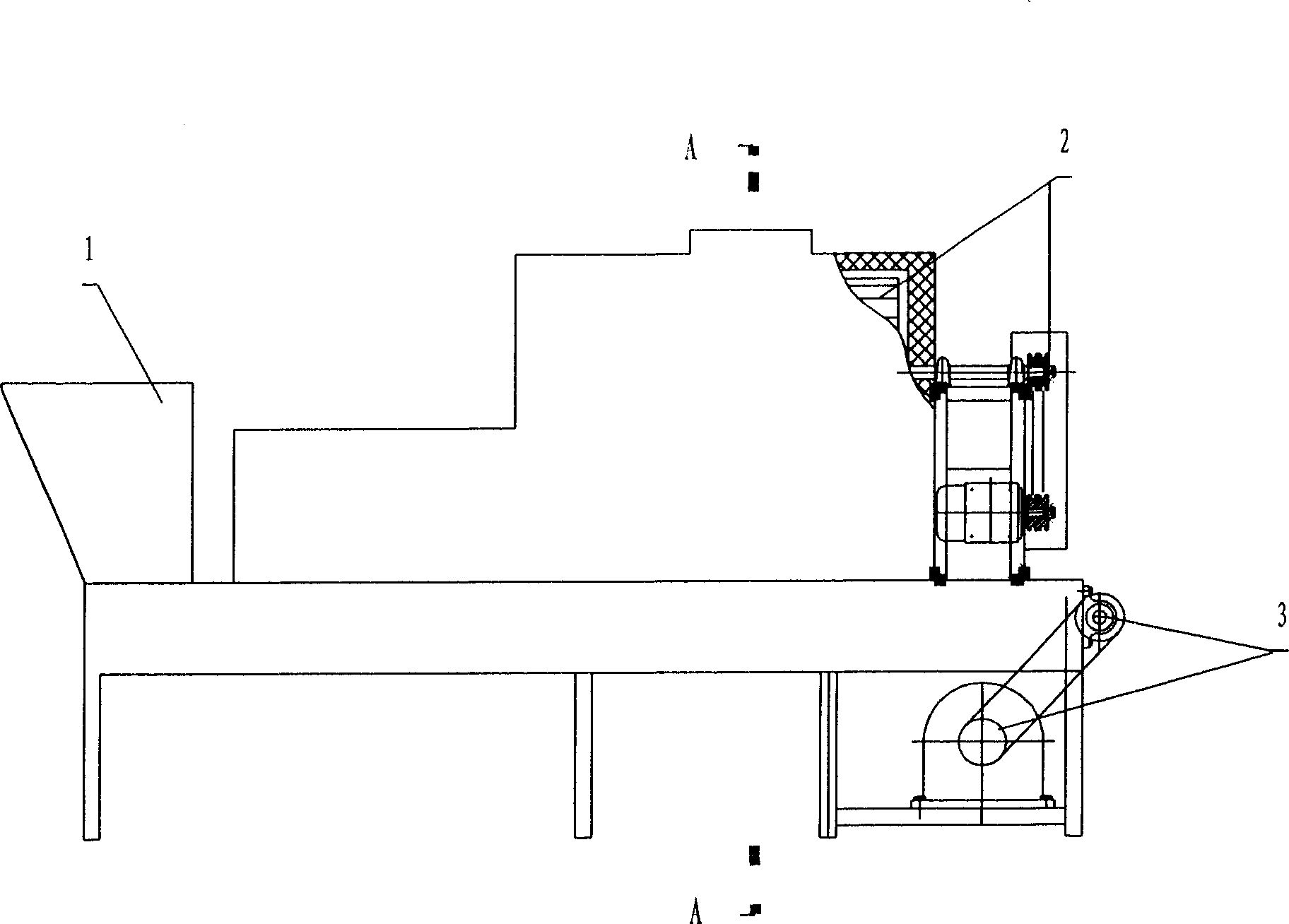

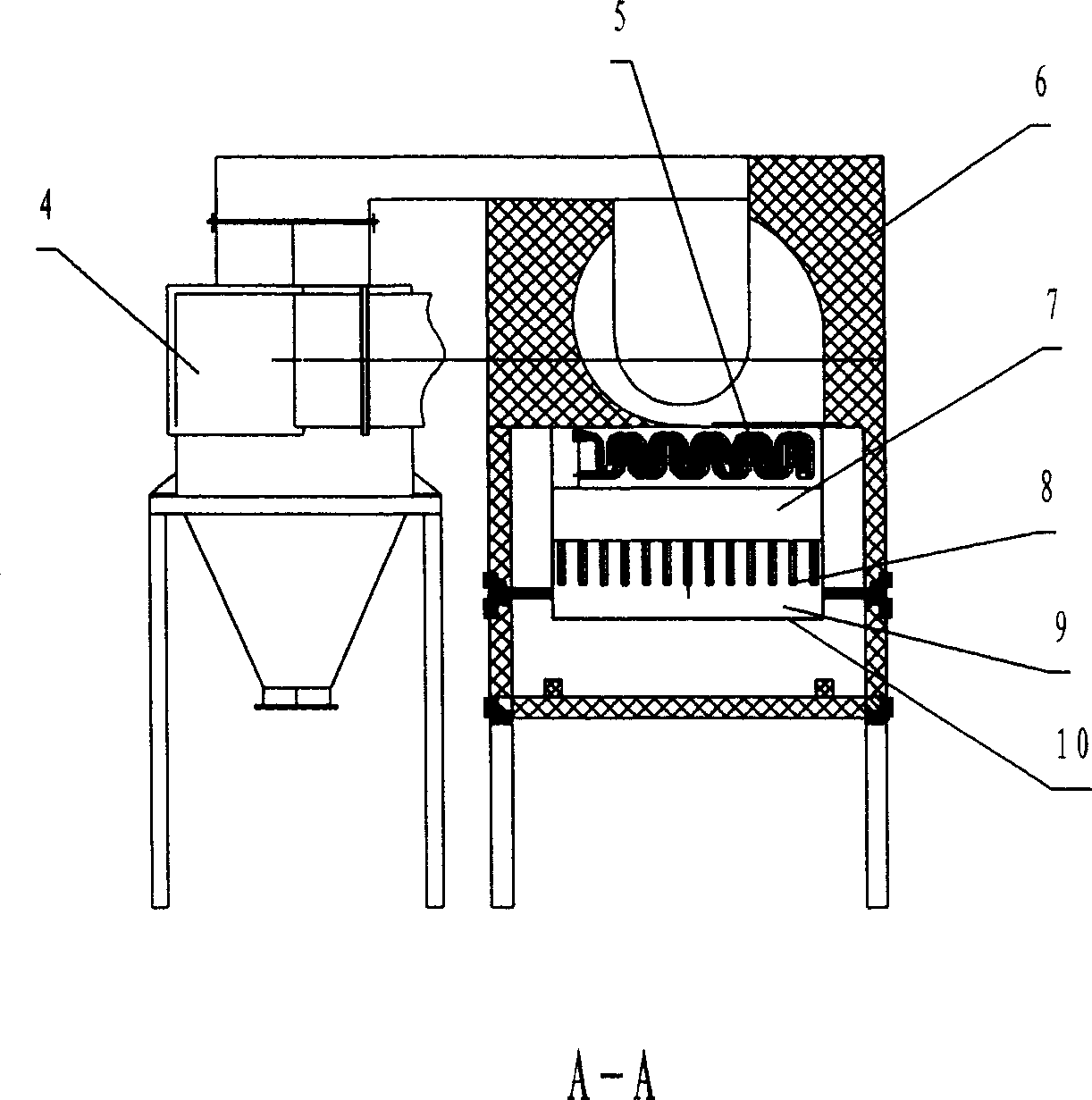

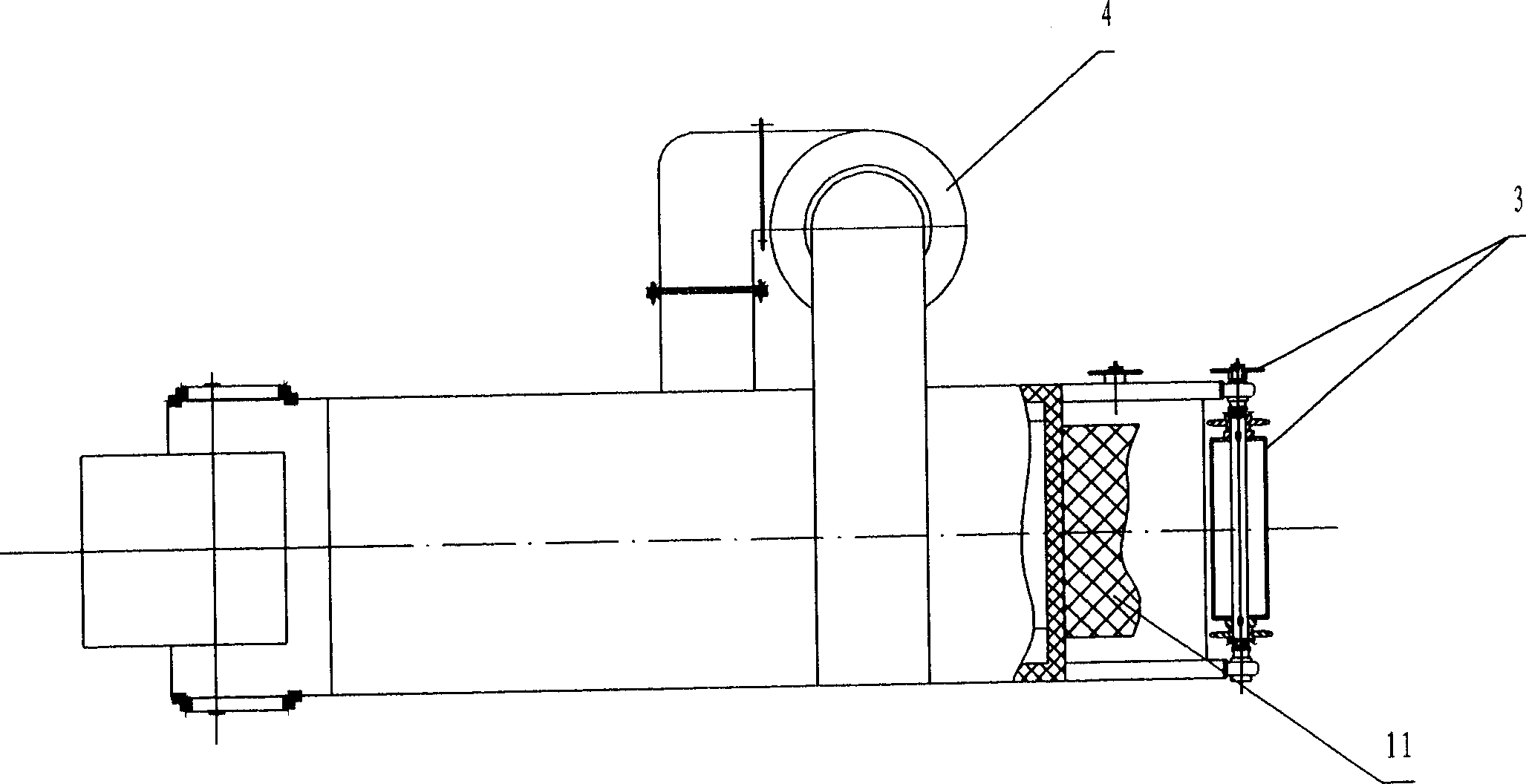

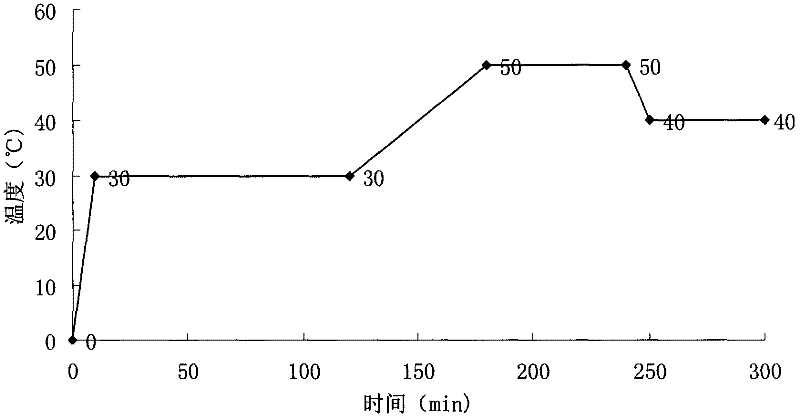

Chestnut shell crashing process and air jet impact chestnut crasher

The present invention discloses a kind of chestnut shell crushing process and air jet impact chestnut shell crusher. The chestnut shell crushing process includes washing, graidng, depurating, and shell cutting and features that after being cut with 1-5 cuts chestnut is impacted under air jet of 5-30 m / s speed and at 100-190 deg.c for 1-60 min inside air jet impact chestnut shell crusher, so that the chesnut shell is separated from its pulp by the steam pressure produced inside the chesnut. The present invention has increased air distributing chamber, air jet and air impact chamber. The present invention makes the shell and its red inner coating separated from its pulp through continuous mechanical operation.

Owner:CHINA AGRI UNIV

Jujube and ginger black sugar

InactiveCN1582747AAlso has an antiemetic effectRich in nutrientsConfectioneryUnknown materialsAdditive ingredientSugar

Owner:天津开发区兰德食品有限公司

Making method of crisp muscle and bone stick

The invention discloses a making method of a crisp muscle and bone stick. The making method of the crisp muscle and bone stick is characterized in that principal raw materials are cut into dices first, matched in a balance mode according to a proportion, subjected to the processes of stirring, pickling, syrup adding and flour wrapping to enrich taste, prefrying, coloring, shaping, cooking and the like, and then quickly frozen and packaged to form a finished product. The making method of the crisp muscle and bone stick organically combines a traditional catering technology and a food engineering technology, exquisite technological operation is conducted, the crisp muscle and bone stick contains no preservative, and the quality guarantee period is one year under the condition of refrigerated storage; the crisp muscle and bone stick is novel, crisp in taste, balanced in nutrition, ready to eat, convenient to eat and healthy. The crisp muscle and bone stick is convenient to eat, delicious, and capable of being eaten after being heated simply.

Owner:河南省淇县永达食业有限公司

Health white spirit containing beneficial functional component

ActiveCN101007992ADoes not change colorDoes not affect the tasteOrganic active ingredientsMetabolism disorderBisulfideDaidzein

The invention discloses a health- caring wine containing good effective element. The wine with alcohol degree being 15- 75 (V / V %) comprises maltol, borneo camphor, cedrol, dimethyl trisulfide, dimethyl bisulfide, ligustrazine, daidzein, crust and puerarin, which not only changes wine color, but aslo does not influence waste, no toxic action. The health- care wine can improve bloos circulation, reduce blood pressure, reduce blood fat and promote circulation of qi and relieve pain, resist tumor and cause head pain after excessive drink.

Owner:SICHUAN TUOPAI SHEDE WINE

Freeze-drying deep-fried dough sticks and production process thereof

ActiveCN102232404AGuaranteed deliciousExtended shelf lifeDough treatmentBakery productsFreeze-dryingAlum

The invention relates to freeze-drying deep-fried dough sticks and a production process thereof, in particular to deep-fried dough sticks. The deep-fried dough sticks do not contain alum or other aluminum-containing additives which have a puffing function, the moisture content of the deep-fried dough sticks is between 5 and 20 percent, an acid value is between 0.1 and 4 mg / g, and a peroxide valueis between 0.005 and 0.25 g / 100g. The production method for the deep-fried dough sticks basically comprises the following steps of: blending, making dough, proofing for forming, frying, freezing and drying. The deep-fried dough sticks are high in forming stability and fragility, low in grease content and long in shelf life, and can be packaged to be stored.

Owner:BEIJING YUSHIYUAN FOOD

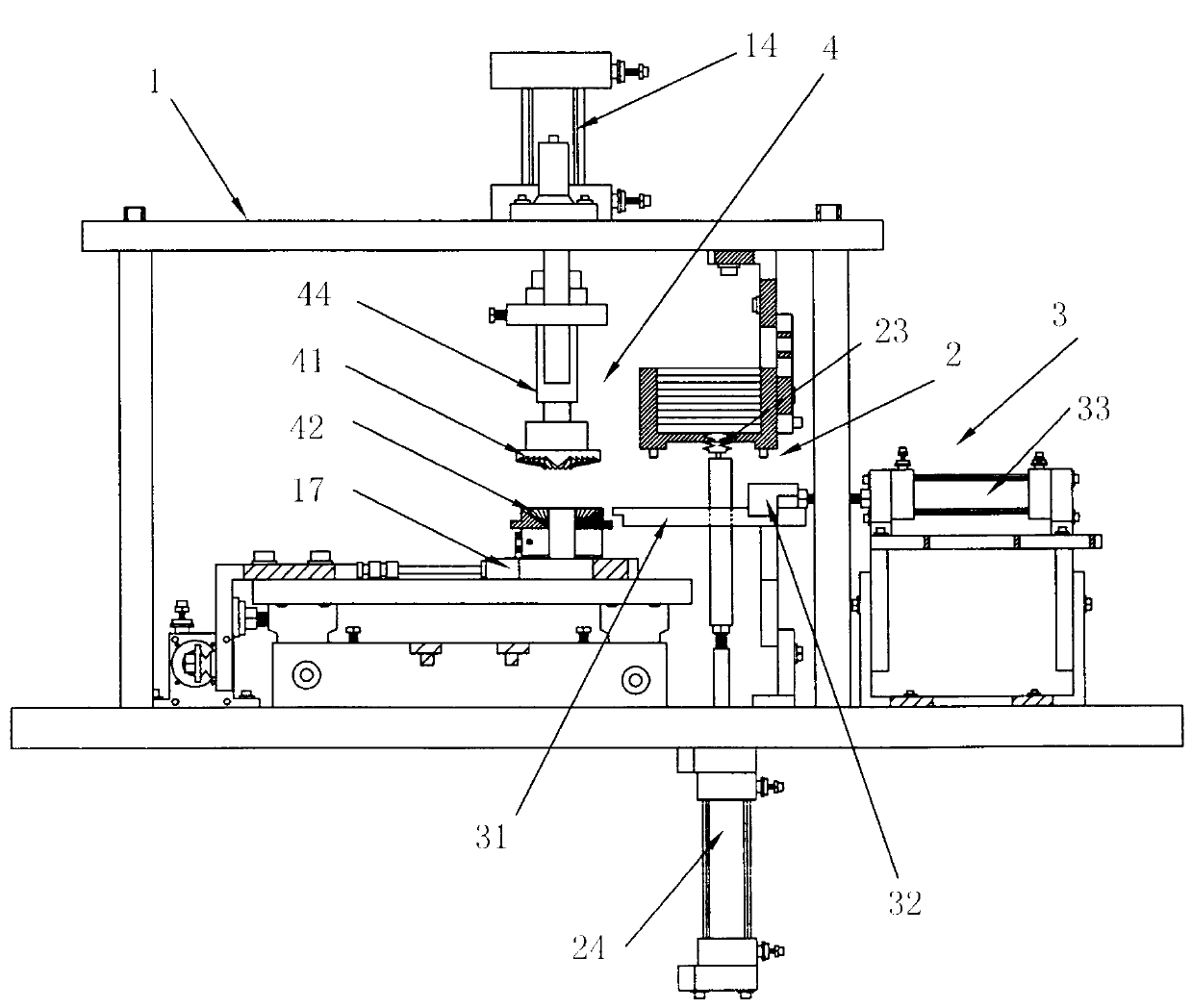

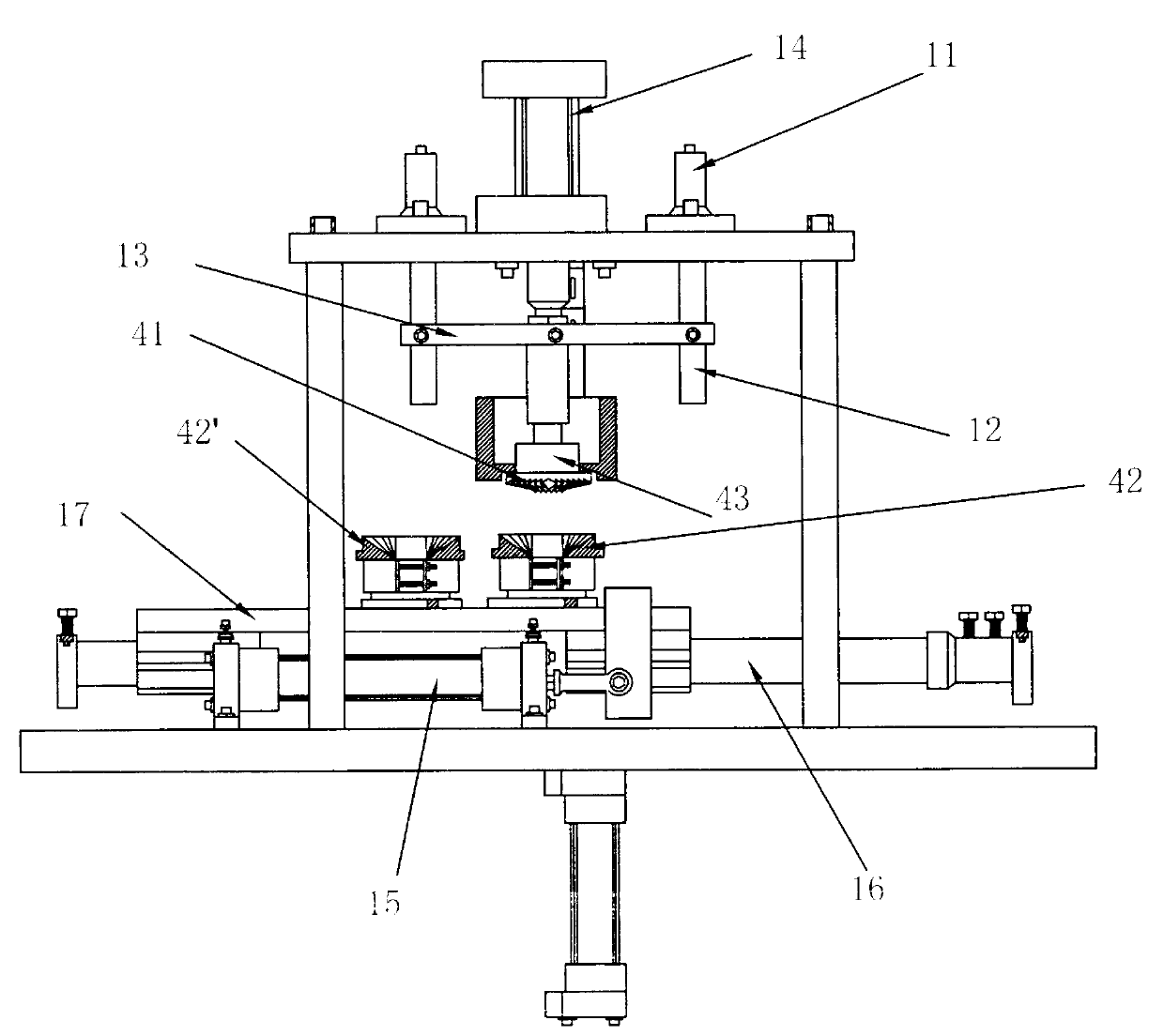

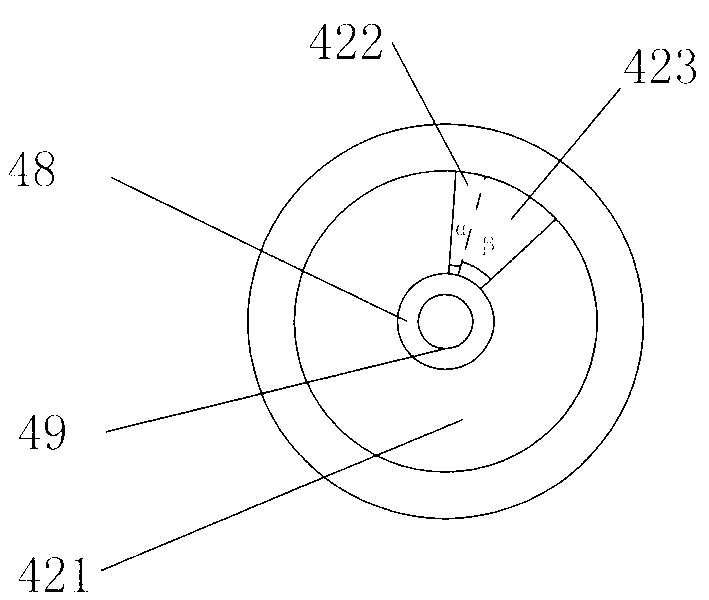

Cake baking paper support forming machine

ActiveCN103342006AEasy to eatFood hygieneEnvelopes/bags making machineryCooking & bakingPulp and paper industry

The invention relates to a cake baking paper support forming machine, in particular to machines for manufacturing bowl-shaped cake baking paper supports. A paper feeding mechanism, a paper conveying mechanism and a paper support punching forming mechanism are arranged on a machine frame of the cake baking paper support forming machine. The paper support punching forming mechanism comprises an upper die and a lower die. The upper die is sleeved outside an ejector rod through an upper die seat. Limiting bosses are respectively arranged inside the upper die seat and outside the ejector rod. The ejector rod and a power source are in transmission connection and movably arranged on the machine frame in an upper-and-down mode. The lower end of the ejector rod is provided with an ejector rod head. The lower die is arranged on the machine frame through a lower die seat. The upper die and the lower die correspond to each other in position in the vertical direction. A cavity is formed in the position of the axis of the lower die and the lower die seat. An inner die is arranged inside the cavity. The inner die is matched with the ejector rod head. A step is arranged between the ejector rod head and the ejector rod. The paper feeding mechanism and the paper conveying mechanism are jointed. The paper conveying mechanism and the lower die are jointed. The cake baking paper support forming machine can manufacture cake baking paper supports full-automatically. Due to the fact that flanging wings are formed at the opening edges of the cup wall of the paper support and used as handheld parts in order to pull open the paper support, the paper support is convenient and hygienic to use.

Owner:RUIAN ZHENGDA MACHINERY CO LTD

A kind of preparation method of aromatherapy leg steak

The invention discloses a method for preparing fragrant smoked leg chops, which comprises the following steps of: pricking peeled chicken thigh meat, adding materials, kneading, pre-cooling, flattening, and sizing; and steaming, baking and curing in a steam box, quickly freezing and packaging. On the basis of catering fragrant smoked leg chops, the conventional catering technology is integrated with a food engineering technology, and pricking and flattening processes are adopted, so that products are deeply tasty, fresh and tender in meat quality and nutritious and have the shelf life of one year when stored in a refrigerator; and the fragrant smoked leg chops are fragrant, tender and juicy in metal quality, refreshing and palatable, unique in flavor, ready to eat, convenient, sanitary, convenient to eat, and delicious, and can be eaten after being simply heated.

Owner:河南省淇县永达食业有限公司

Kidney bean leisure foods and preparation method thereof

The invention discloses kidney bean leisure foods and a preparation method thereof. The kidney bean leisure foods are prepared from kidney beans serving as main raw materials through a process of the combination of soaking, boiling, soaking and roasting. The special production technology of the combination of soaking, boiling, soaking and roasting is adopted, so that the original shapes of the kidney beans and nutrient substances of beans are retained, the foods have soft, sweet and moist mouthfeel, and the selection space of leisure diet of people is enriched.

Owner:BEIJING YUSHIYUAN FOOD

Skin care composition

InactiveCN102764228AInhibition formationSynergistic freckle removal is goodCosmetic preparationsToilet preparationsWrinkle skinCo enzyme q10

The invention discloses a skin care composition. The skin care composition comprises raw materials of, by mass, 1.0-60.0 % of coenzyme Q10, 0.1-20.0 % of lily extracts, 0-60.0% of natural vitamins E, 0-5.0 % of rose essential oil, 9.5-90.0 % of olive oil and 0-25.0% of bee wax, and the percentage of the raw materials totals 100%. The skin care composition not only can be used externally, but also can be taken orally and has obvious effects of removing freckles, whitening skins and preventing wrinkles.

Owner:GUANGZHOU LEEHE HEALTH PRODS TECH

Meat of instant Chinese hamburger and industrialization manufacturing method thereof

The invention relates to meat of instant Chinese hamburger and an industrialized manufacturing method thereof, which is meat of instant Chinese hamburgers bagged, bowled or quality guaranteed at ordinary temperature, can be eaten instantly and heated in a short time, thereby enabling Chinese hamburgers to be a convenient and rapid food. The invention comprises the following components (by the weight part): 90 to 110 parts of streaky pork, 2 to 6 parts of cooking wine, 0.8 to 2.2 parts of scallion, 0.8 to 2.1 parts of ginger, 0.6 to 0.9 part of crystal sugar, 2 to 12 parts of soy sauce, 2 to 5 parts of salt, 0.03 to 0.1 part of fennel, 0.1 to 0.5 part of schisandra, 0.8 to 2.2 part of aniseed, 0.12 to 0.8 part of cassia bark, 0.12 to 0.3 part of prickly ash, 0.12 to 0.3 part of spiceleaf, 0.12 to 0.2 part of clove, 0.08 to 0.12 part of tsaoko cardamom, 0.12 to 0.4 part of amomum, 0.12 to 0.4 part of long pepper, 0.001 to 0.2 part of nutmeg, 0.1 to 0.15 part of hexyl malt powder, 0.6 part of gourmet powder, 100 parts of water and soup stock in proper amount.

Owner:刘建才

Novel sausage- roasting device

The invention relates to a novel sausage roasting device, comprising an insulation shell, a heating body and a sausage containing cavity body, which is characterized in that the sausage containing cavity body is arranged in the heating body which is internally provided with an encryption charcoal layer, and the charcoal layer is provided with a heating pipe used for containing solid heating agents, and the sausage containing cavity body is a cylindrical space with a hollow sausage containing pipe inside. When in use, articles that need to be roasted are put in the sausage containing pipe and the solid heating agents are put in the heating pipe. At last, the procedure is finished with a cover covered and the device is ignited from a lower opening of the heating pipe. The invention has the advantages of facilitating heating sausage in a unique design manner, healthy eating, and containing other food in the sausage containing pipe.

Owner:天津金秦实业发展有限公司

Production process of chili beef fat

The invention discloses a production process of chili beef fat. The production process is characterized by comprising the following steps: step 1, preparing chilies into glutinous rice cake chilies; step 2, putting beef fat, broad bean paste and the glutinous rice cake chilies into a wok to be stir-fried, wherein the stir-frying temperature is controlled to be 100-120 DEG C, and the stir-frying time is controlled to be 15-120min; step 3, performing filtration or centrifugation; step 4, performing flavoring; and step 5, sterilizing internal packaging materials with ultraviolet light for 3h or more, and then, performing packaging after sterilizing. The chili beef fat produced by the production process disclosed by the invention takes the beef fat as a raw material, can not influence the bodyhealth of people, has effects of resisting cancers and the like, has excellent taste and fragrance, and can be easily accepted by consumers.

Owner:GUANGHAN HANGJIA FOOD CO LTD

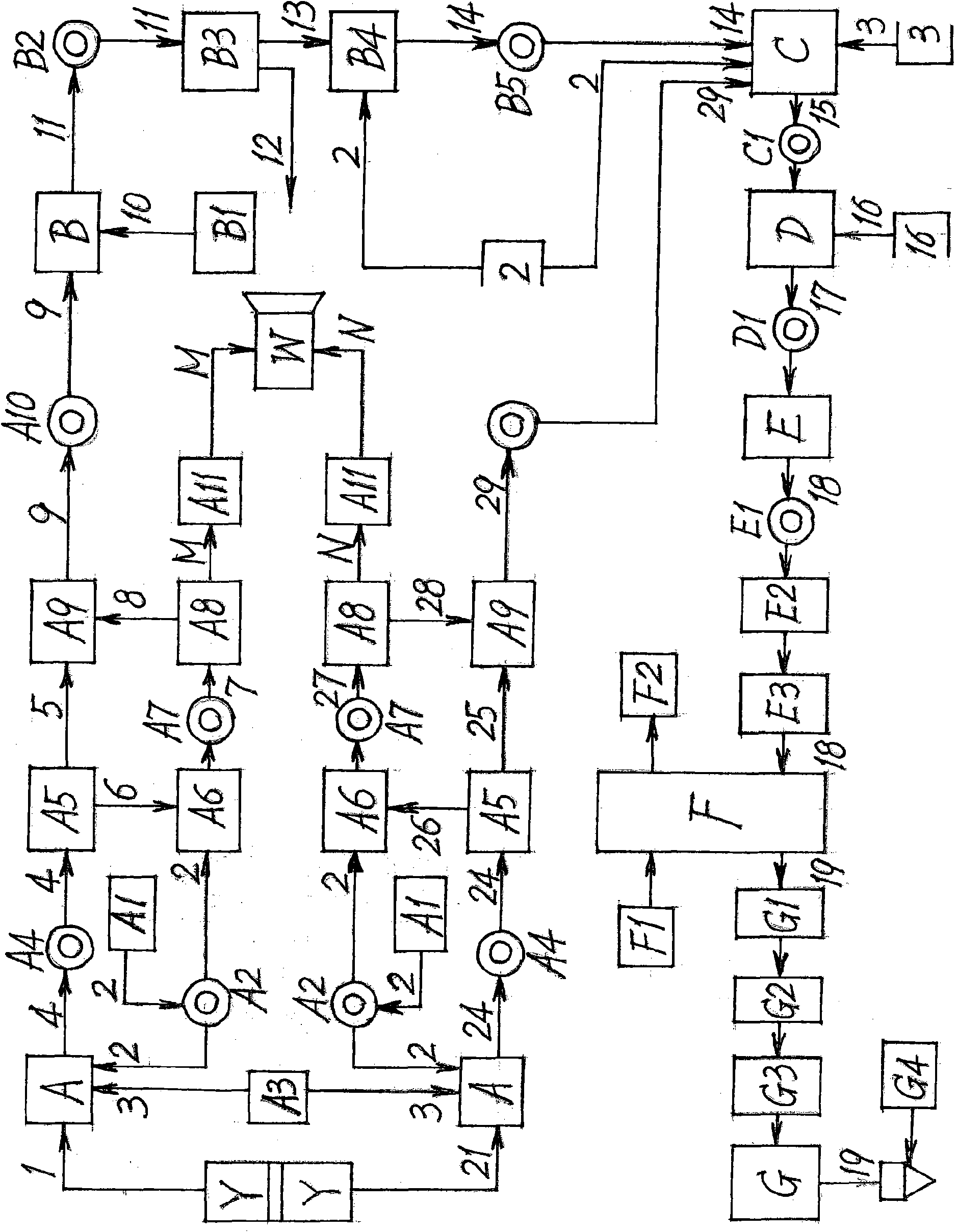

Production technology of dual-crop compound protein isolates

ActiveCN101558814AReasonable process routeClosely connectedProtein composition from vegetable seedsFood preparationProtein isolateProtein C

The invention relates to a production technology of dual-crop compound protein isolates, which comprises the followings: low-temperature soybean meals (1) are prepared into soybean emulsion of acid sediment (14) through extraction and acid sediment procedures; peanut flour (21) can be prepared into peanut extractive and mixed emulsion (29) through an extraction procedure; the soybean emulsion of acid sediment (14) and the peanut extractive and mixed emulsion (29) are added into a neutralization tank (C) based on the proportion for mixing, stirring and confecting; the emulsions are prepared into neutralized solution (15) through a neutralization procedure; the neutralized solution (15) is prepared into enzyme solution (17) through an enzymolysis procedure; the enzyme solution (17) is prepared into flashing liquid (18) through a sterilization procedure; the flashing liquid (18) is prepared into compound protein isolates (19) with protein content more than or equal to 90% through a drying procedure and finally the compound protein isolates (19) enter warehouses after being packed and detected through packing and detecting procedures. The production technology features compact procedure linkage and complete device configuration, can fit the demand of scale serial production, promotes the increase of deep processing conversion rate and utilization factor of farm products and conduces to optimizing industrial structures and product structures of soybeans and peanuts to realize industrialization. The prepared product combines the characteristics of both soybean protein isolates and peanut protein isolates and has rich nutrition, wide application and high added value of products.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Processing method for freezing chives

InactiveCN104082398ALong storage timeSimple preparation processFruit and vegetables preservationPreservativeEngineering

Owner:LIJIANG SANCHUAN IND GRP

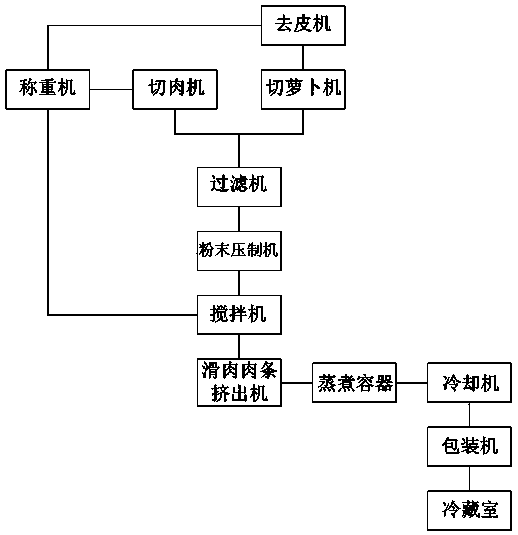

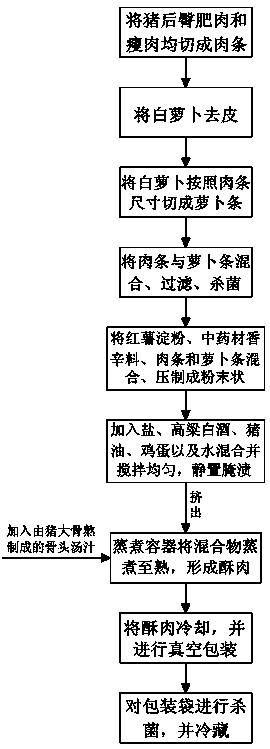

Crispy meat as well as preparation method and equipment thereof

InactiveCN103859426AReasonable collocationReasonable dosageFood preservationFood preparationBiotechnologyLean meat

The invention discloses crispy meat as well as preparation method and equipment thereof, and solves the problem that existing crispy meat difficultly meets the requirements of people on mouth feel, nutrition and safety. The crispy meat comprises the following raw materials: 300g-500g of sweet potato starch, 300g-600g of a big pig bone, 80g-110g of pig rump fat meat, 180g-200g of pig rump lean meat, 80g-100g of white radish, 40g-60g of salt, 40g-50g of sorghum liquor, 40g-60g of lard, 90g-100g of eggs and 0.46g-0.64g of Chinese herbal medicine spice. The crispy meat is delicious in taste, smooth in mouth feel and fat but not greasy, the quantity of heat and content of fat and cholesterol can be effectively controlled, and no hormone or preservative is added to the crispy meat, so that the crispy meat is safe and nontoxic, and has the advantages of being rich in nutrition, healthy and safe to eat and is very suitable for popularization and application.

Owner:杨田

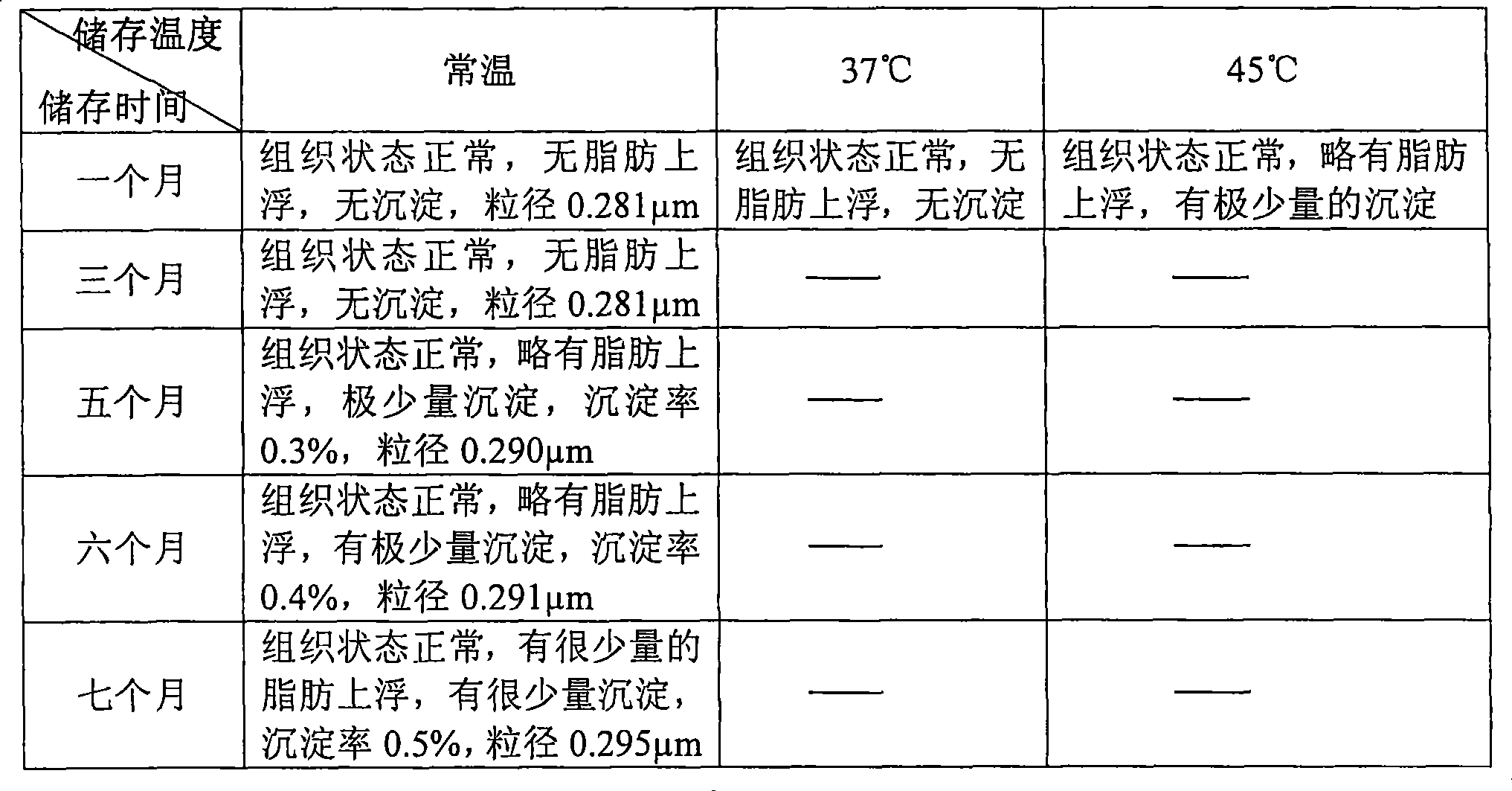

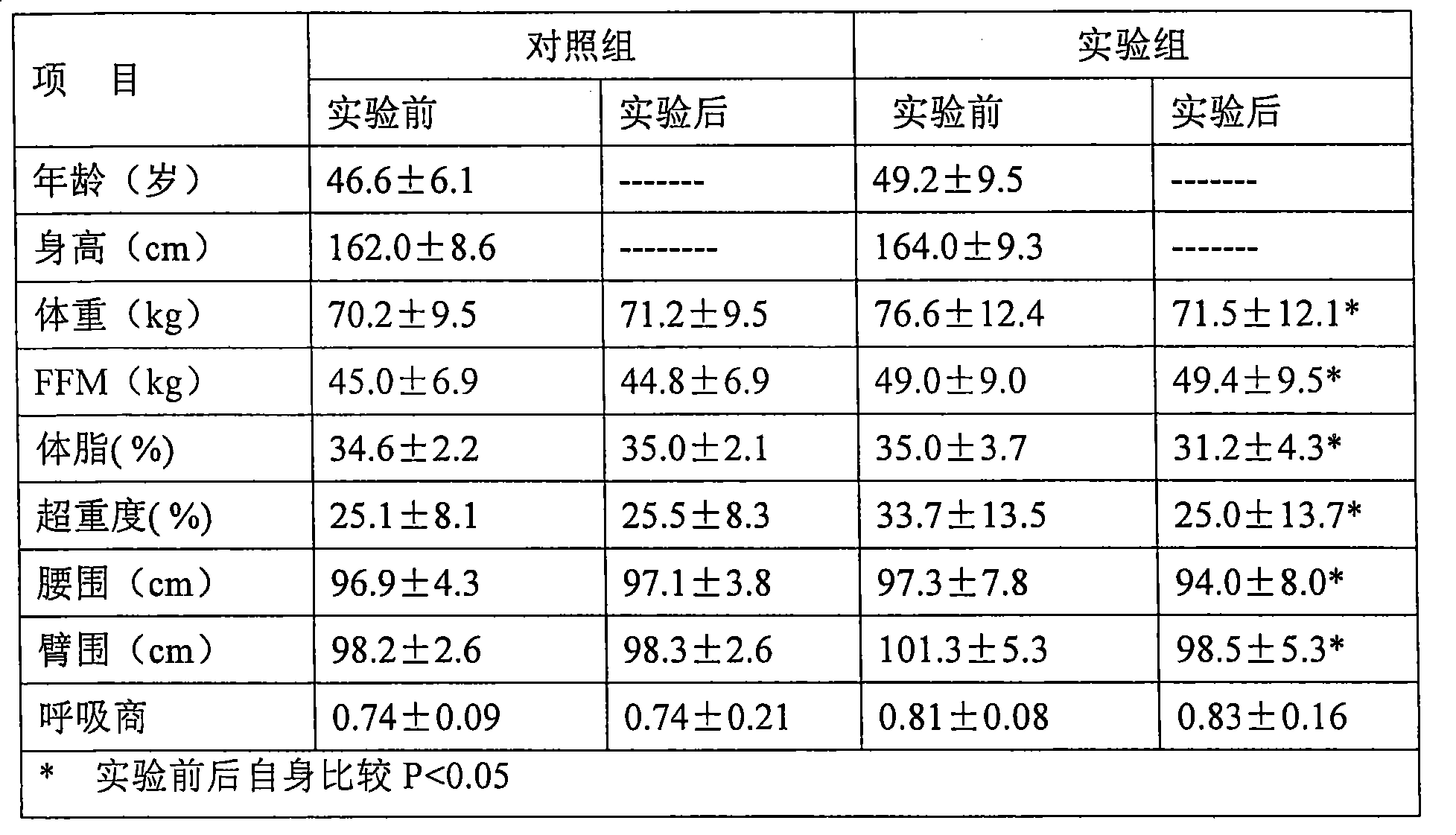

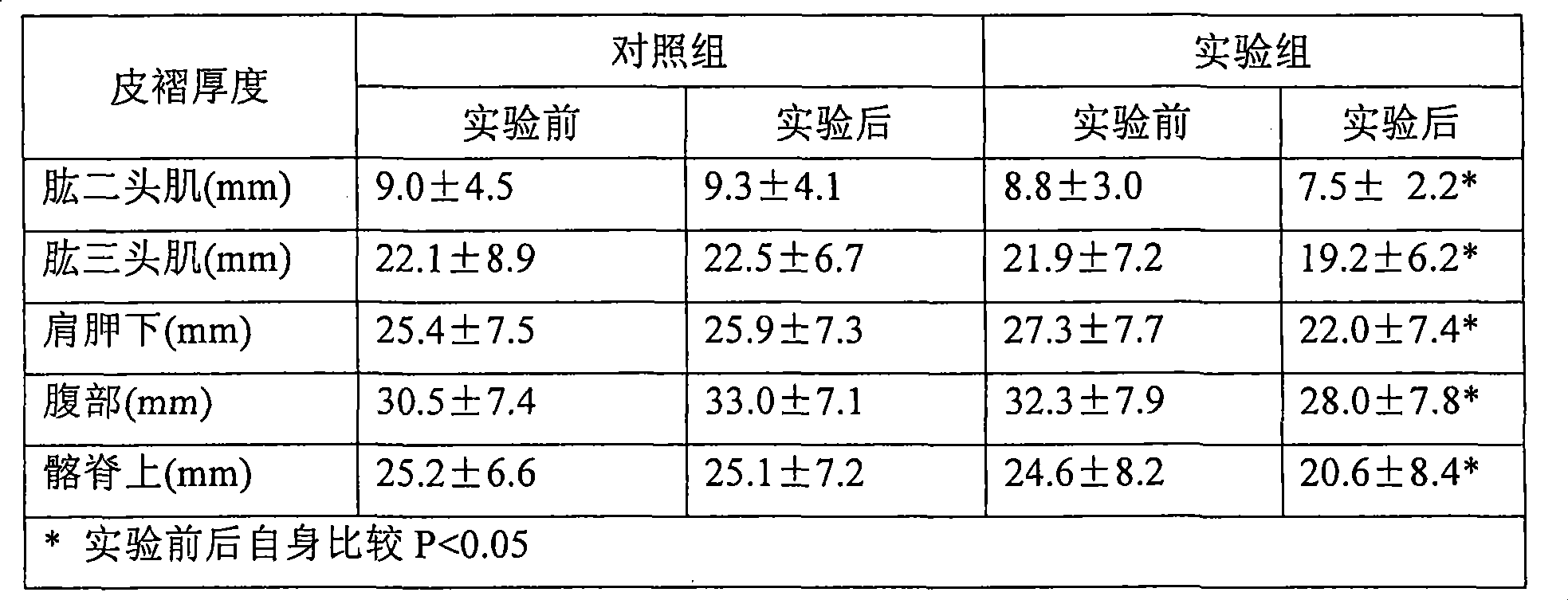

Liquid milk product added with levorotation carnitine and producing method thereof

ActiveCN101427708AWide and popular drinkingEasy to drinkMilk preparationFood preparationLiquid productLiquid milk

The invention provides a liquid milk and production method thereof, wherein the ram material of the liquid milk comprises: equal to or more than 80wt% of milk, 0.06wt%-0.5wt% of L-carnitine, 0.05wt%-0.2wt% of emulsifier. The L-carnitine of specific amount and the normal milk are mixed together, therefore the obtain milk has weight-reduction function and is convenient for drinking at any moment therefore the body weight can be controlled after long-time continuous drinking and the liquid milk has good shelf-life stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Toona sinensis sprout pickling method

InactiveCN104187505AMaintain nutritional valueGreat tasteFruits/vegetable preservation using acidsFood preparationToona sinensisMouthfeel

The invention discloses a toona sinensis sprout pickling method belonging to the technical field of food processing. Specific machining process includes recovery-cleaning-blanching-cooling-pickling-packaging, the toona sinensis sprout pickling method effectively solves the problems that toona sinensis sprout is short in fresh eating time, and not resistant to storage, the beneficial effects are that: the pickled toona sinensis sprout can be stored for more than 2 years, can effectively maintain the emerald green color of the toona sinensis sprout, shows a natural color, can keep the original nutritional value, tastes good, always maintains the fresh, sweet, fat and crisp characteristics, and is resistant to store, convenient to carry and healthy to eat.

Owner:黄振忠

Onion bactericidal fermented chicken food bag and preparation method thereof

InactiveCN106307144ABeneficial tasteGreat tasteFood ingredient as taste affecting agentNatural extract food ingredientsNutritive valuesBiotechnology

The invention discloses an onion bactericidal fermented chicken food bag. The food bag is prepared from, by weight, 200-210 parts of chicken, 40-45 parts of onions, 21-24 parts of dried small shrimps, 20-30 parts of pumpkin seeds, 2-3 parts of dendrobium officinale, a proper amount of lactic acid bacteria, a proper amount of seasoning, a proper amount of soybean oil and a proper amount of water. Rich processing raw materials are adopted for the food bag, the main material chicken is pickled and fermented with lactic acid and then is reasonably matched with various auxiliary materials such as onions and dried small shrimps, and then sauce-frying processing is carried out, so that rich nutrients are contained in the food bag, the nutritive value is improved, and the food bag has a bactericidal effect when eaten, can whet the appetite and is nutritional, sanitary and convenient to eat.

Owner:安徽兆味源食品科技有限公司

Sour murraya euchrestifolia processing method

InactiveCN104686969ARemove fishy smellUnique flavorClimate change adaptationFood preparationBiotechnologyEngineering

The invention discloses a sour murraya euchrestifolia processing method, and belongs to the technical field of food processing. The specific processing process includes the seven steps of picking at proper time, cleaning and screening, airing, blanching, pit extruding, pickling, canning and exposure. The method effectively solves the problems that sour murraya euchrestifolia manufacturing is complex in procedure and sour murraya euchrestifolia is not easy to store. The method has the advantages that sour murraya euchrestifolia is completely manufactured with hands, the processed sour murraya euchrestifolia can keep natural color of murraya euchrestifolia, is uniform, can be stored over 3 years, does not contain preservatives, is unique in flavor and sour in taste, can effectively eliminate stink odor of some meat, can help digestion, reduces fat, invigorates the stomach and the spleen, increases appetite and is convenient to carry and hygienic to eat, and the method is easy and convenient to use and easy to operate.

Owner:黄振忠

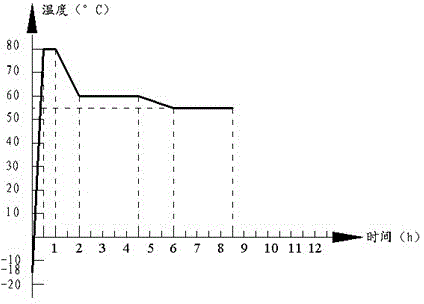

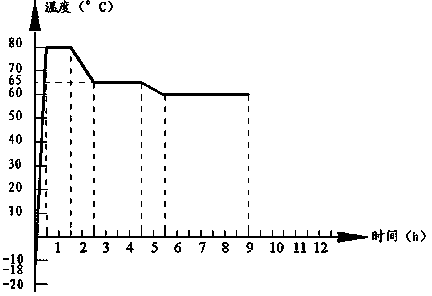

Frozen processing method for pignolia

InactiveCN104068100AThe production process is simpleLong storage timeFruits/vegetable preservation by freezing/coolingNutrientProcess engineering

The invention relates to the field of food processing, in particular to a frozen processing method for pignolia. The frozen processing method comprises the following steps: selecting fresh pignolia, drying and slicing after cleaning; freezing pignolia quickly; drying the quick-frozen pignolia. The frozen processing method is simple in technique, and the obtained pignolia effectively retains the various nutrients, color, smell and taste of pignolia; the pignolia is free of the addition of any grace agents or preservatives in the preparing process and healthier and safer to eat, can be stored at room temperature for a long time, and has wide market prospects.

Owner:LIJIANG SANCHUAN IND GRP

Process for extracting sesame oil

InactiveCN106635386AReduce pollutantsAvoid harmFatty-oils/fats refiningFatty-oils/fats productionSesamumPesticide residue

A process for extracting sesame oil comprises the steps of screening, ultrasonic cleaning, seed frying, grinding into thick liquid, static settlement and filling and the like. The screening and ultrasonic cleaning technology is adopted, pollutants of sesame raw material are reduced to the largest extent; particularly, harm to the human body caused by heavy metals and pesticide residue can be avoided fundamentally, so that he sesame oil is eaten more hygienically and safely; a pure physical extraction process is adopted, specific natural nutrient substances and performances of sesame are reserved to the largest extent, and substances harmful to the human body are not generated; the prepared edible sesame oil has no thick sesame oil smell, is natural and pure in taste, sparkling and crystal-clear in color, mellow and normal in taste and more suitable for high-temperature vegetable cooking and has distinct characteristics.

Owner:安徽新创智能科技有限公司

Hot pepper paste and method for making the same

InactiveCN101116496AEasy to carry and eatChange the way of eatingFood preparationZanthoxylum bungeanumMaterials science

The present invention relates to a capsicum paste and the fabrication method thereof, wherein the capsicum paste mainly consists of components as follows: capsicum (10-20 shares), vegetable oil (5-10 shares), rock candy (2-6 shares), vegetable mud and / or fruits mud (20-25 shares), salt (4-8 shares), fennel powder (0.1-0.2 shares), powder of Zanthoxylum Bungeanum Maxin (0.1-0.2 shares), sauce (2-5 shares), and fresh ginger powder (0.2-0.4 shares), and the fabrication method is as follows: the fresh capsicum or the dried capsicum is grinded into powder more than 80 meshes, added with vegetable oil, rock sugar, salt, fennel powder, powder of Zanthoxylum Bungeanum Maxin, sauce, fresh ginger powder and vegetable mud and / or fruits mud, as well as the water as the adjuvant material, to obtain a paste, which is stirred evenly and heated under 100 DEG C for 10 minutes, sealed for 1 hour, cooled down to obtain the capsicum paste. The capsicum paste provided by the present invention is not only easy to carry, but also convenient for eating with sanitation and convenience.

Owner:王文军

Flavor egg garlic production technology

InactiveCN105077356ASuitable for industrial production operationsFor long-term storageFood preparationFlavorSugar

The invention discloses a flavor egg garlic production technology. Flavor egg garlic comprises unprocessed garlic flakes, cooked eggs, cooked corn kernels, salt, sesame oil and white granulated sugar. The proportioning design is improved, packaged egg garlic is produced, the processing flow is standardized, and therefore the flavor egg garlic production technology is suitable for industrial production operation. The flavor egg garlic can be stored for a long time and is hygienic to eat and easy to popularize. The exquisitely-packaged egg garlic is supplied to a market, and people can enjoy delicious egg garlic without hands-on operation.

Owner:江茗铭

Method for making space egg cake

The invention discloses a method for making a egg cake. The method comprises the following steps of: stirring egg liquid, putting the stirred egg liquid into a die for molding and roasting, putting fillings on the roasted egg sheets, freezing and packaging. On the basis of catering egg cakes, the conventional catering technology and the food engineering technology are combined organically; by strict process operation, original nutrition, such as rich proteins and the like, is retained basically; the egg cake does not contain chemical additives and preservatives; under the condition of refrigeration, the quality guarantee period lasts one year; the egg cake tastes soft and is smooth and delicious; and as the space egg cake is defrozen and instant, the egg cake is convenient and sanitary. The egg cake is convenient to eat, namely that the space egg cake can be enjoyed by simple heating.

Owner:河南省淇县永达食业有限公司

Process for preparing sesame oil

The invention relates to a process for preparing sesame oil. The process comprises the following steps of: removing impurities from sesame serving as a raw material, roughly washing the sesame, immersing and flushing the sesame, dehydrating and drying the sesame until the water content is reduced to 4.5 to 7wt%, then baking until the water content is reduced to below 2.5wt%, squeezing by a vertical type hydraulic squeezing machine at low temperature to obtain oil, and performing natural sedimentation and filtration on the squeezed rough oil to obtain the edible sesame oil. The technical steps are reasonable; the process is easy to operate; the prepared sesame oil has no rich sesame oil flavor; the flavor is natural and pure; the gloss is clear and crystal; the taste is mellow; and the original essence in the sesame can be retained to the maximum extent.

Owner:SHANGHAI LIANGYOU GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com