Chestnut shell crashing process and air jet impact chestnut crasher

A technology of gas jet and shell breaking machine, which is applied in the fields of shelling, food processing, pod removal, etc., can solve the problems of low production efficiency, insignificant economic benefits, and low depuration rate of red clothes, so as to improve labor productivity and ensure Quality and flavor, the effect of shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

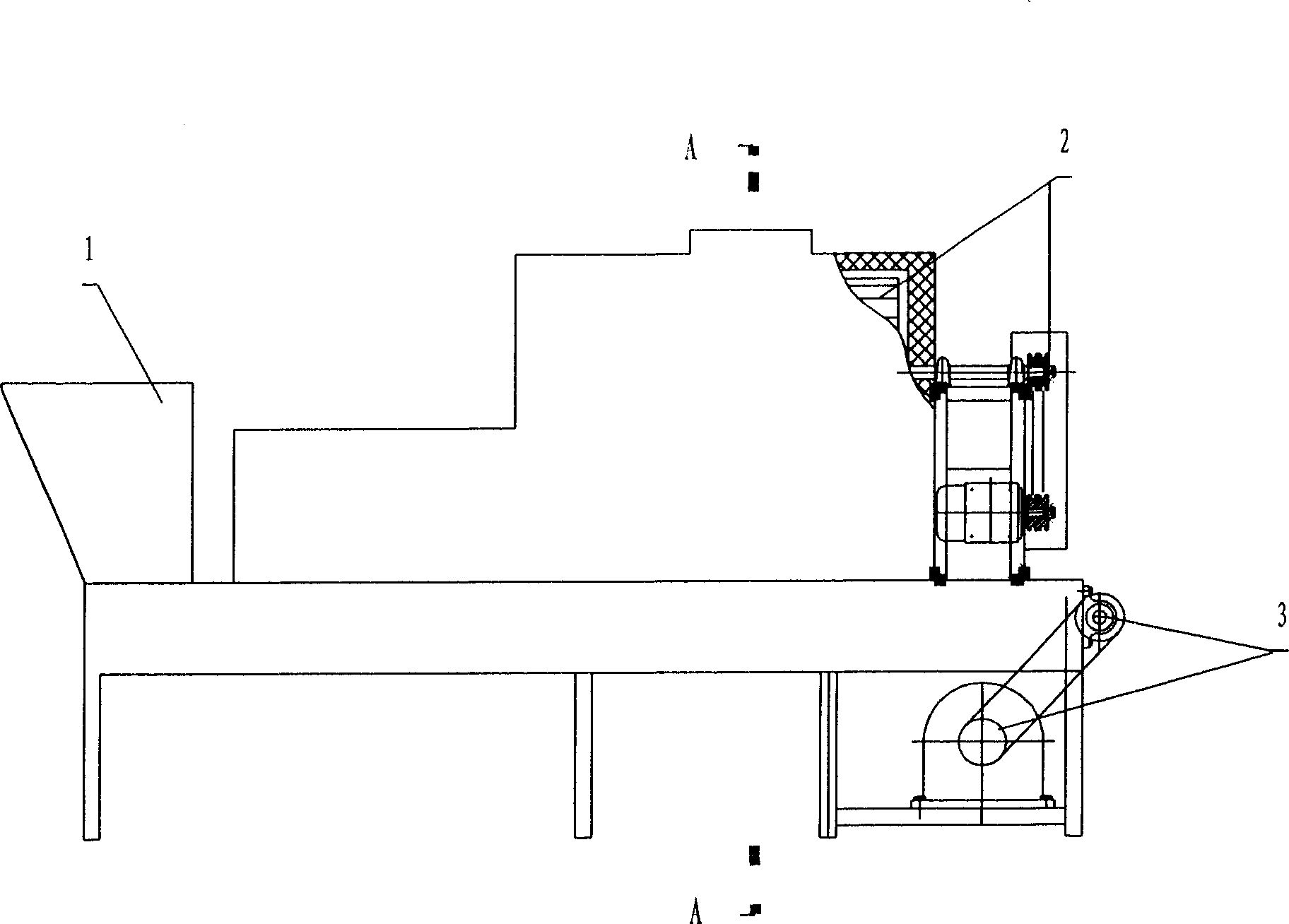

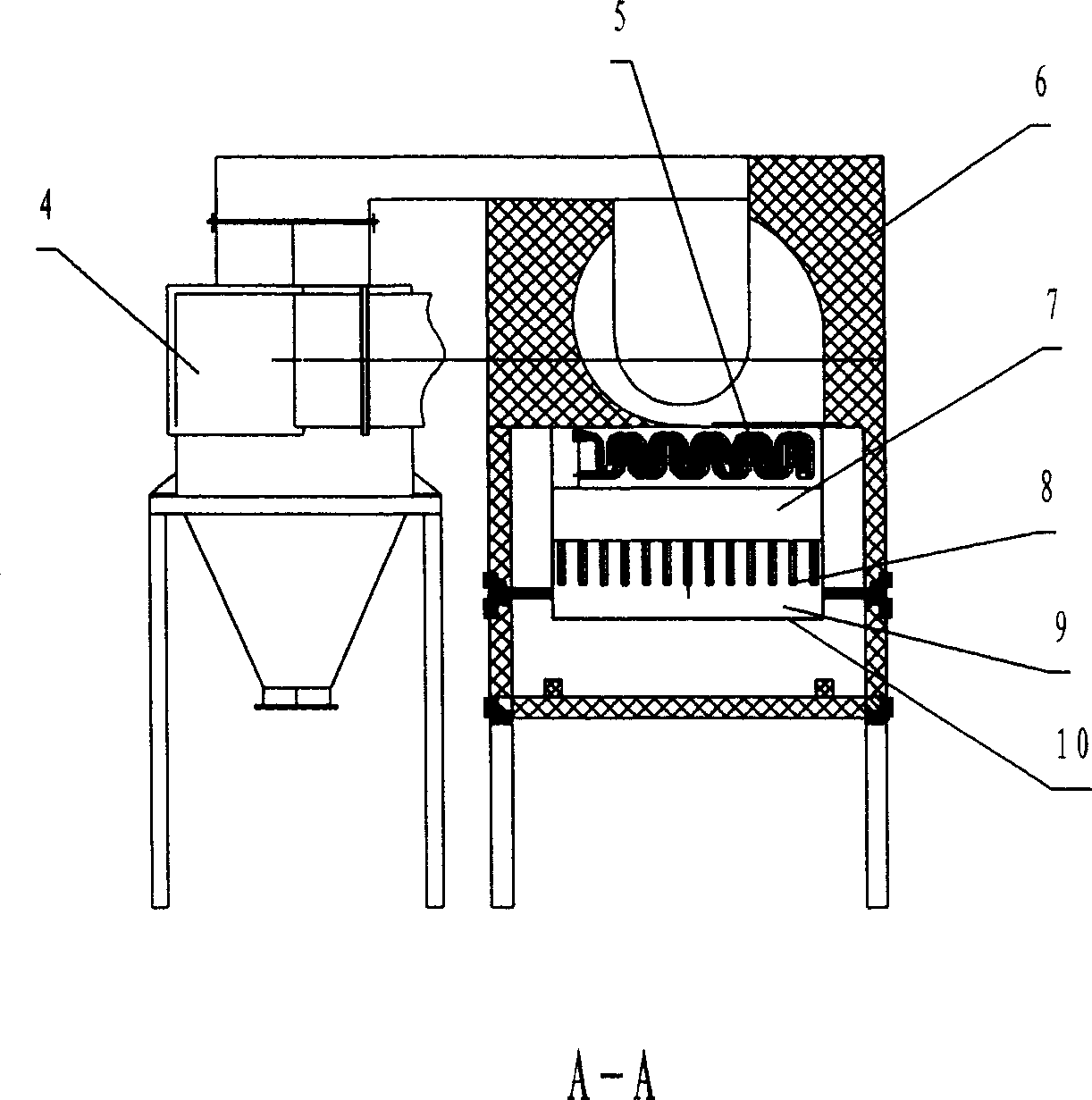

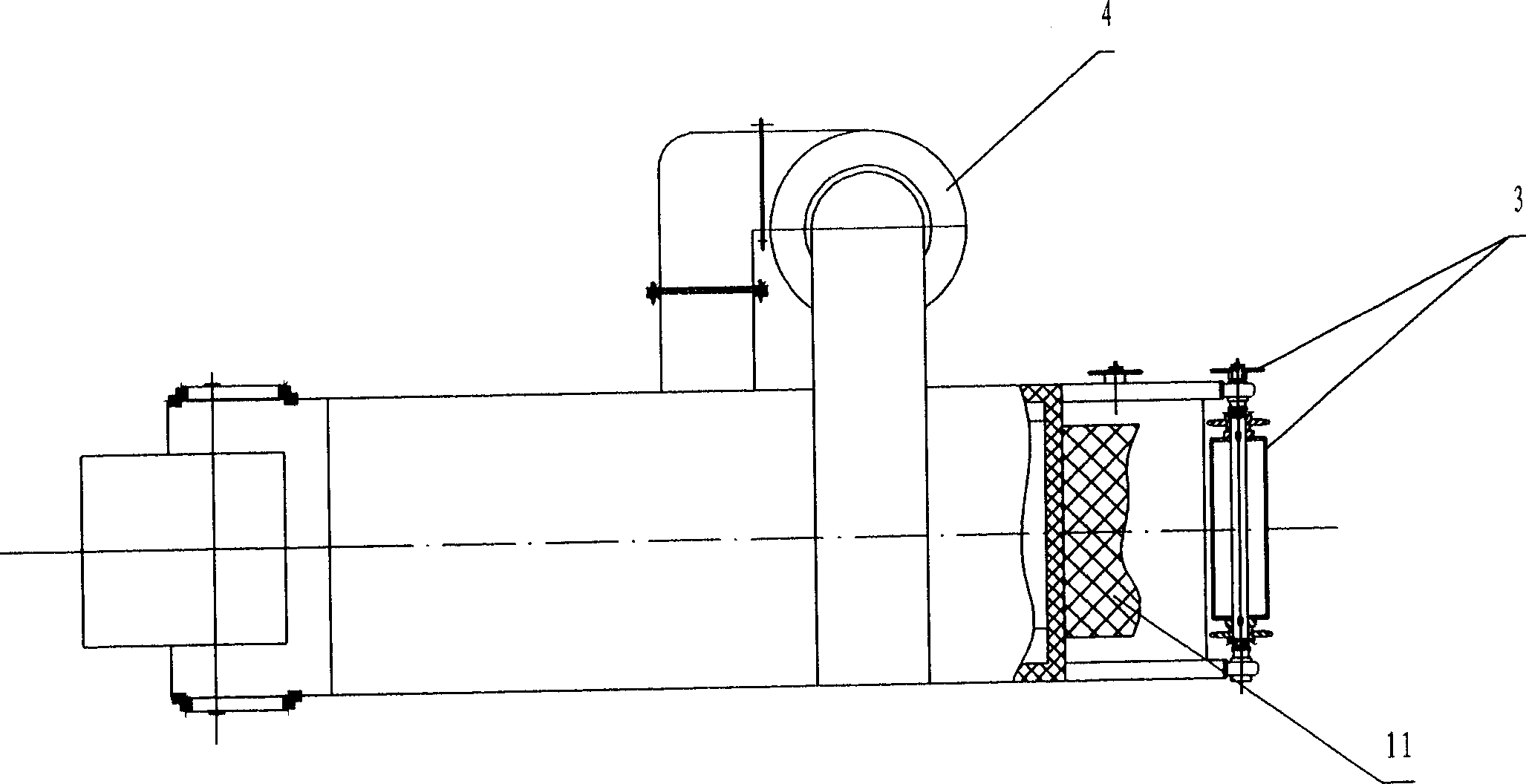

[0030] As shown in the figure, the present invention includes a feeding hopper 1 , a fan system 2 , a transmission device 3 , a heating device 5 , a material support device 11 , a bottom plate 10 and an insulation layer 6 . It is characterized in that a gas distribution chamber 7 is provided behind the heating device 5; a gas impact chamber 9 is provided above the material supporting device 11; the gas nozzle 8 is connected with the gas distribution chamber 7 through a pipeline. An exhaust gas recovery and dehumidification section 4 is provided above the side of the gas impingement chamber 9 . The installation angle of the gas nozzle 8 is 60-120 degrees to the horizontal plane. The material supporting device 11 is a grid-like movable conveyor belt.

[0031] Chestnuts after grading, cleaning, removing impurities, and cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com